af DS - 07SS 809293 Macville PS 12 måneder siden

176

Dredging in the Sumpter Valley

af DS - 07SS 809293 Macville PS 12 måneder siden

176

Mere som dette

It was later shut down later on in 1924 by the company.

3. The Winchman

2. The Rear Oiler

1. The Front Oiler

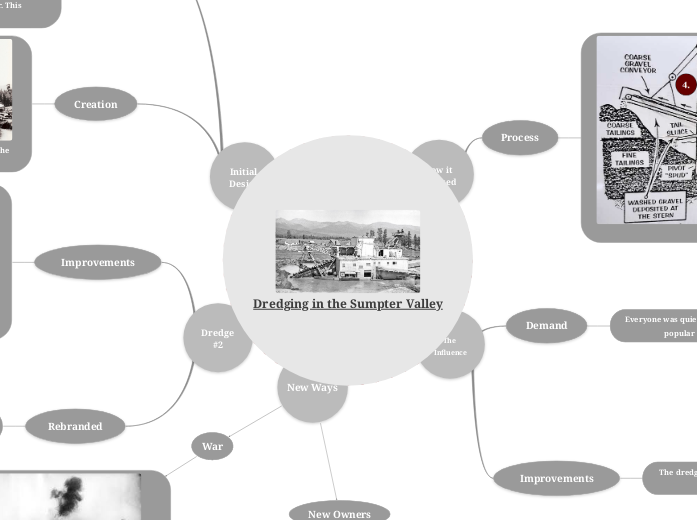

2. The buckets would then dump the gold-laden into a hopper at the top of the dredge, which would be flushed forward by 36 feet by water into a trommel (a metal drum which rotates).

3. As the the material turned, another water line would "wash" it. This would result in the smaller pieces of material to drop down to the trommel's shell, while larger pieces continued towards the stacker.

4. The larger pieces would then go to the end of the dredge to be put into the piles of tailings out back.

5. The smaller pieces would be flushed by sluice boxes that had slats called riffles which would cause heavy materials like gold to be trapped, while lighter opens would also go out back.

While being the owners of the dredge, they were able to make the efficiency of the gold recovery system go from having a 70% rate of recovery to 95% by using a jig system instead.

In 1950, Baker Dredging Company sold it to another company who went by the same name as the previous one, but are different, Powder Dredging Company.

Their goal was to catch more gold than the other dredges, but that goal backfired on them as they didn't achieve it and to run the operation become more pricey after the war.

The ended the dredging on August, 1954, and this entire project resulted in them being $100 000 in debt.