Alex and Manroop

Company Background

The Beginning

Nike was founded in Eugene, Oregon, United States, by coach Bill Bowerman on the 25th of January 1964. The current CEO/ President is John Donahoe, and the headquarters is in Beaverton, Oregon. Nike products are manufactured in Vietnam, China, and Indonesia and their goods are distributed globally to 170 countries.

coach Bill Bowerman

Type of Business (Ownership)

/GettyImages-184826718-56a27df55f9b58b7d0cb45fc.jpg)

Nike has corporate ownership/general public ownership. This means that the business is owned by its shareholders. The general public holds a 12% stake in the company. Not all of this 12% own the company, the shareholders elect a board of directors to oversee the corporation's activities.

Size

Nike is a large multinational corporation due to its globalization/global brand divisions.

Brand Divisions

North America

Europe, Middle East & Africa

Greater China

Asia Pacific & Latin America

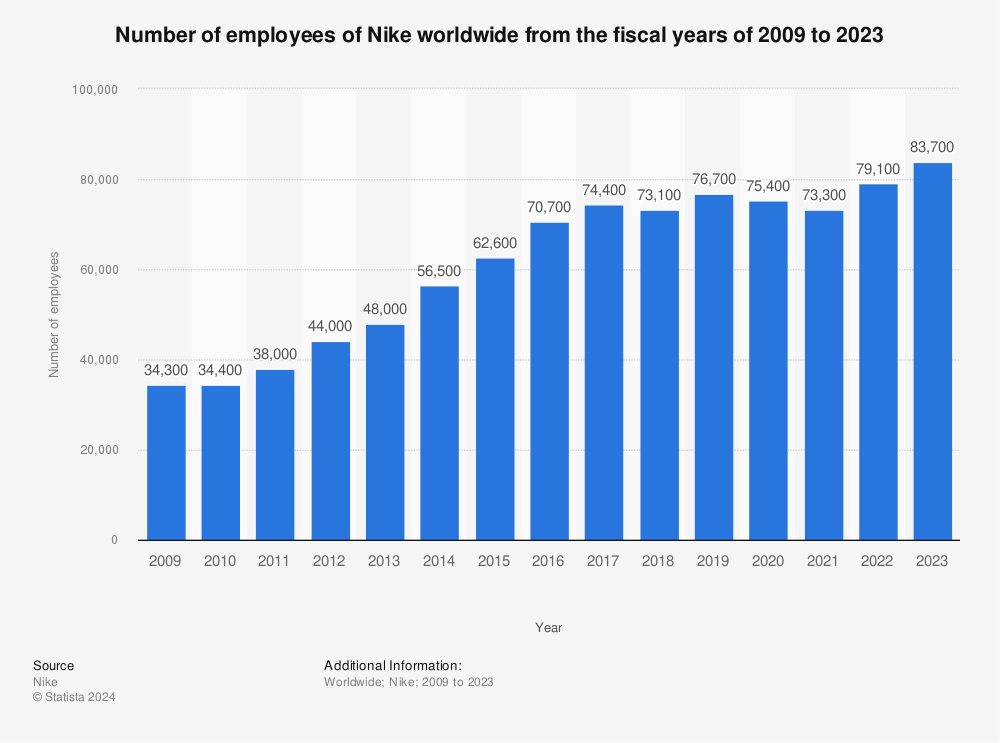

In the past five years, Nike, Inc.

employed over 70,000 people worldwide.

Goods/Products Sold

Neccessity or Need?

Nike’s biggest segments are clothing, footwear and equipment. I consider equipment to be a luxury good whilst clothing and footwear are essential goods. However, Nike's prices tend to be higher than other companies, this makes me consider it both essential and luxury goods.

Products Offered

dassdf

Slogan

Environment Initiatives

Nike is one of the most environmentally friendly shoe manufacturers because they have taken a massive step to reduce their carbon footprint by reusing/ recycling plastics, yarn, and textiles. Firstly, One hundred percent of cotton that the company uses in shoes is certified organic, recycled, or cotton from better initiatives. This benefits the environment because Nike recycles more than 1.5 million pounds of cotton each year, and their shoe soles consist of 50% recycled manufacturing waste. In addition, all of Nike's recycled polyester comes from plastic bottles that undergo processes to become high-quality yarn. Specifically, the bottles go through processes that start by being shredded into flakes, converted into pellets, and spun into the polyester. Furthermore, the recycled nylon yarn reduces carbon emissions by up to 50% compared to virgin nylon. It is transformed from various materials, like carpets and used fishnets. Notably, in 2020, all of Nike's air manufacturing innovation facilities in North America were powered by 100% renewable wind energy which is a massive achievement to becoming emissions free. In conclusion, Nike takes many steps to ensure that its manufacturing process has less environmental impact when compared to other major companies by recycling/ reusing materials.

Production equipment and materials

Natural resources

Nike utilizes a variety of natural resources

industries/sectors to produce its sneakers.

The two main ones are agriculture which

includes the animal resource and land

resource industry. The natural gas industry

is also important to shoe production.

Agricultural:

Plant Fibers - Plants that are farmed and

used in shoe production (agricultural

natural resource)

Cotton

Sustainable cotton: Nike’s goal is to use 100% sustainable cotton by 2020, which means only using certified organic

and recycled BCI licensed cotton.

Linen

Hemp

Bamboo

Ramie

Coconut

Rubber (Ruber Tree)

Animal Fibers - Naturally farmed animals that

later turn into raw materials used to produce

shoes

Cows - Leather

Silkworm Caterpillars - Silk

Sheep - Wool

Synthetic fibers:

These materials are the least sustainable because they do not exist in nature and come from oil (crude oil industry)

They are made of petroleum, the raw materials that come from this naturally produced petroleum include

Polyester

Nylon

Polyurethane

Acrylic

Raw materials/ ingredients

:

Rubber(nike shoes use 70% environmental friendly rubber)

Recycled polyester(Nike recycled 82 million plastic water bottles to make polyester

100% of cotton is certified organic, recycled, or cotton sourced through better initiatives

Recycled Nylon sourced from carpets and fishnets

EVA Foam (Ethylene Vinyl Acetate)

Eva Foam is one of the most efficient and cheap materials that Nike uses in their shoes

Synthetic leather(man made fabric that is more breathable and easier to clean)

Leather(LWG-certified)

Supplies

:

-Sewing machines

-Cutting presses

-Conveyor belt(assembly line)

-Outsole press

-Foot wear primer and cement

Types of Labour

Physical Labor

:

Occupations:

-Factory workers(assemblers)

-Product quality management(Tester, etc)

-Safety specialist

-Truck drivers

-Packers

Intellectual Labour

:

Occupations:

-Material manufacturing manager

-concept designer

-Footwear designer

-Art director

-Human Resources(HR)

-Customer Service

-Senior marketing analytics director

-Finance Manager.

-Senior project manager

Competition

Nike’s main competitor is Adidas. Even though Nike earned $29.538 billion more revenue than Adidas in 2021, Adidas is growing at a higher rate. They have a growth rate of 17.8%, while Nike has a 6.8% increase. Nike has to keep on introducing new designs to stay on top of the footwear market.

Trends

All of Nike's shoes are marketed as high-performance sports footwear. Alternatively, Adidas's current footwear marketing strategy is superior and markets its sportswear shoes to be used in casual settings as well as in sports. Adidas even partners with celebrities like Kanye West to make Yeezys, which is one of the trendiest and exclusive sneaker series with a revenue of over 1.7 billion.

Adidas(Casual)

Nike(Sport)

In order for Nike to continue growth, they must expand to different designs that are more appealing to a variety of ages, not just focus on youth.

New technologies

Nike air technology:

Shoes with this technology have less midsole foam and a large volume of pressurized air (nitrogen) filled bags for lighter weight and maximum cushioning. It’s like walking on air because the shoe absorbs impact.

Nike flyknit:

Made of strong and lightweight strands of yarn that have been woven into a one-piece upper, securing an athlete's foot to the shoe platform. The main benefit is that this helps to reduce manufacturing waste by 60% while being lightweight and breathable, which is perfect for athletes.

Nike react foam

The unique composition gives runners foam that is lighter, softer, and more responsive than ever.

Nike flyprint

Nike is now utilizing 3D printing technology to create the upper portion of the shoe. These 3D textiles allow the shoe to be more breathable because less material is used, resulting in it being lighter. A huge benefit of printed textiles is greater precision because there is no warp or weft of yarn.

Africa

The most appropriate leadership style for manufacturing Nike shoes would be Democratic. I believe that every employee should have a voice in the creation process, whether it is during designing or assembly. Getting feedback from factory workers can be essential to making the production line more efficient, and every one of the designer's ideas/concepts should be taken into consideration.