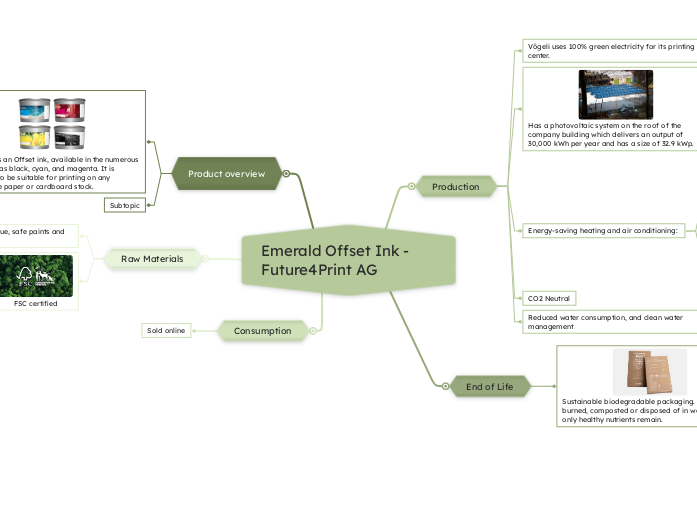

Emerald Offset Ink - Future4Print AG

Production

Vögeli uses 100% green electricity for its printing center.

Has a photovoltaic system on the roof of the company building which delivers an output of 30,000 kWh per year and has a size of 32.9 kWp.

Energy-saving heating and air conditioning:

Using two boreholes up to nine meters deep around the printing works, water is extracted from the ground and used to cool the printing machines and the printing room.

With the waste heat generated from production, machine cooling and air conditioning, the entire property can be heated without heating oil or other heat sources.

CO2 Neutral

Reduced water consumption, and clean water management

End of Life

Sustainable biodegradable packaging. Whether burned, composted or disposed of in waste paper, only healthy nutrients remain.

Product overview

Emerald is an Offset ink, available in the numerous hues such as black, cyan, and magenta. It is designed to be suitable for printing on any absorptive paper or cardboard stock.

Subtopic

Raw Materials

Ecological paper, non-toxic glue, safe paints and pigments, VOC-free products

FSC certified

Consumption

Sold online

Sun Chemical company

(historically)

Product overview

Sun Chemical Company is a provider of Inks and pressroom products, colour materials and advanced materials

Production

Uses both sustainable and unsustainable packaging

Paper, cardboard, cardstock

Plastic, metal, film

Hazards & environmental impact

Health risk: Petroleum based inks contain VOCs and contribute to long term health problems

Environmental risk: VOCs emersion contribute to air pollution and water contamination

End of life

Product gets thrown away

Recycling: limited recycling dues to petroleum contents. Some inks were recovered for reuse

Disposal: The product would have most likely landed in landfills, been incinerated or into the water

Market0specific disposal: newspaper were often recycled but packaging inks could persist in water waste

Raw material

Historically Sun Chemical company's ink included:

- Petroleum based solvents

- Pigments from chemical plants

- polymer-based resin

- Additives

Most raw materials were either sourced from crude oils or Chemical synthesis

To gain the crude oils they often used pipelines, tankers or trucks

Pigments and additives are shipped in bulk directly from Chemical plants

consumption

Market sold in

Packaging industry (food label, boxes etc.)

Publishing: newspaper, magazines)

Commercial printing (Advertisement)

Shipping & distribution

Transported via trucks, ships, and trains in steal or plastic containers

Packaging: historically they used non-recyclable plastic drums (modern day they used eco-friendly containers)

Price points

Petroleum-based inks were cheaper than soy or water based

price depended on ink type, quantity, and pigment composition