von Peter Kraft Vor 2 Jahren

264

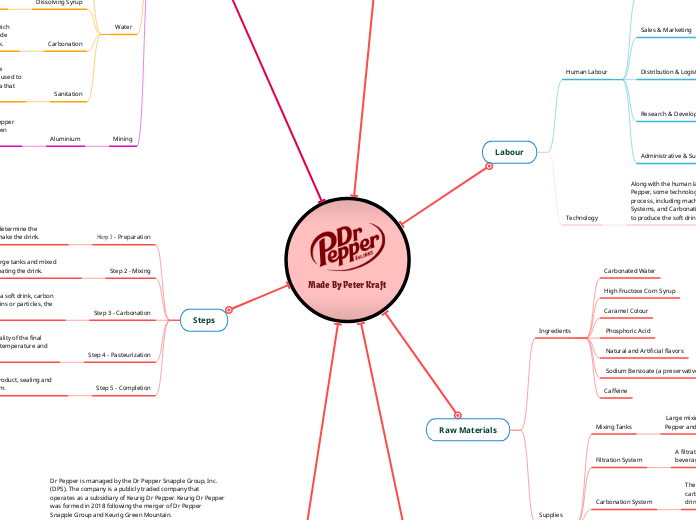

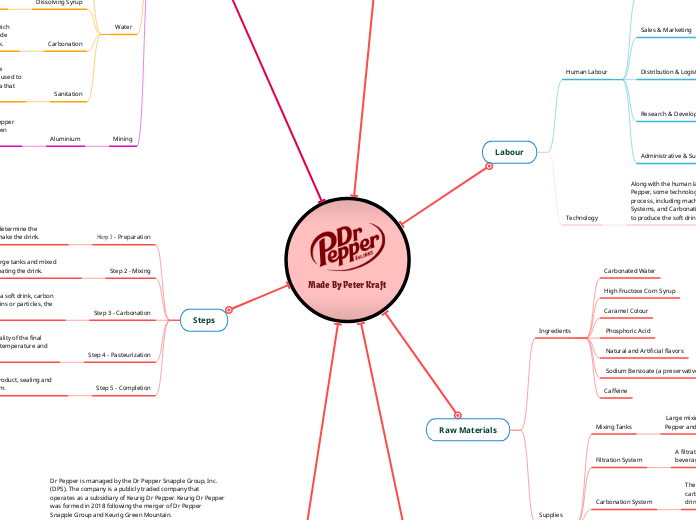

Made By Peter Kraft

von Peter Kraft Vor 2 Jahren

264

Mehr dazu

Aluminium is used to produce the cans in which the Dr Pepper drink is in. The Aluminium is mined from the earth and then used to create the cans that hold the drink.

Water is used for cleaning and sanitation throughout the production process to ensure that the equipment being used to produce the drink are free of contaminants and bacteria that may negatively affect the final product.

Water is also used to add carbonation to the beverage, which gives it its fizziness. The water is infused with carbon dioxide under pressure, which creates the carbonation in the drink.

Water is used to dissolve the high fructose corn syrup and cane sugar used to sweeten the beverage. The water is heated to help dissolve the sweeteners, forming a syrup.

Water is used to mix the ingredients used in the production of Dr Pepper, including the sweeteners, flavorings, and carbonation.

Dr Pepper contains a blend of natural and artificial flavors, including fruit juices and extracts such as cherry and vanilla.

Dr Pepper is also sweetened with cane sugar in some countries where the Soft Drink is produced and sold.

Corn is used to produce high fructose corn syrup, which is a sweetener used in the Dr. Pepper Soft Drinks.

Forklifts and other material handling machinery used in the manufacturing process are powered by propane.

Trucks and other vehicles used to transport raw materials and completed goods to and from the production plant are powered by diesel or gasoline.

The production process's boilers, which provide steam to heat and combine the components, are run on natural gas.

Electricity is needed for the production process to run a variety of machinery, including pumps, conveyors, and mixers. Fossil fuels, nuclear power, and renewable energy sources including solar, wind, and hydropower are commonly used to produce electricity needed for the production process of the Dr. Pepper Soft Drink.

To ensure the safety and quality of the final product, cleaning and sanitation equipment is needed to keep the production facility and equipment clean and free of contaminants or bacteria.

Dr Pepper is packaged in aluminum cans, plastic bottles, or glass bottles, which require filling and packaging equipment. This equipment includes filling machines, labeling machines, and packaging machines.

The Carbonation System gives the Dr Pepper drink its carbonation and fizzy taste by adding carbon dioxide to the drink.

A filtration system is used to remove any solids from the beverage before it is packaged.

Large mixing tanks are used to mix the ingredients for Dr Pepper and are made of stainless steel.

Dr Pepper employs workers in administrative and support roles, such as accounting, human resources, and customer service.

Dr Pepper employs scientists, engineers, and other professionals in research and development to develop new products and improve existing ones.

Dr Pepper employs workers to manage its distribution and logistics operations, including drivers, warehouse workers, and supply chain specialists.

Dr Pepper employs sales representatives and marketing professionals to promote its products and build relationships with retailers and distributors.

Dr Pepper employs workers in its production and manufacturing facilities to operate machinery, assemble and package products, and ensure quality control.