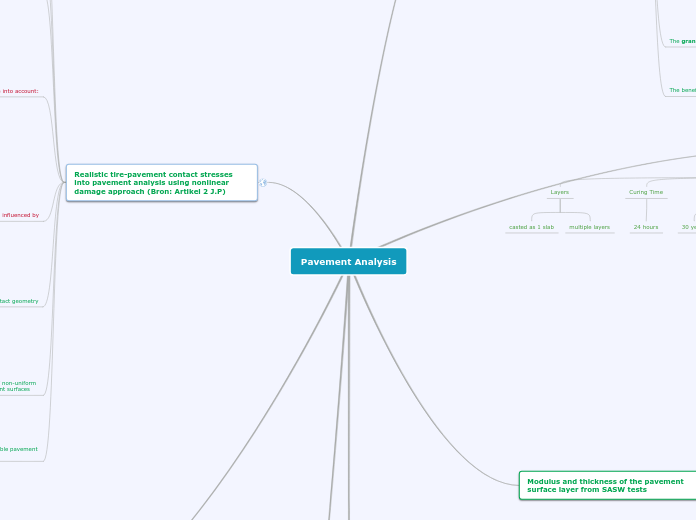

Pavement Analysis

usage of ground penetrating radar for pavement layer thickness analysis

multilayer pavement

radarwaves return an penetrate each junction between the layers

different layers are recognizable

types of ground that are tested

concrete

asphalt

reliability

very promising technique

still needs a lot of testing

radar

radar waves are transmitted then the amplitude and the time of each is collected

Effects of pavement thickness

Asphalt layer

vertical deformation will increase when layer gets thicker

Formula:

d=a(1 − b^h1), where a and b are both unknowns, d is the deformation and h is the thickness => non-linear!

Gravel base

vertical deformation will decrease when layer gets thicker

optimal thickness 60cm

Realistic tire-pavement contact stresses into pavement analysis using nonlinear damage approach (Bron: Artikel 2 J.P)

Solutions for stresses on flexible pavement response:

Distribution on pavement rutting potential

Vertical load shape

The effect of the increase of non-uniform contact stresses on pavement surfaces

Rutting

Near-surface cracking

Including topdown cracking

Pavement damage

Influence of the load contact geometry

Viscoplastic responces

The visco-elastic

The residence times

The stress distribution influences

Contact stresses caused by tires are influenced by

Slip rations

The condition of tire movement

Vehicle speed

Including the tire inflation pressure

Important parameters to take into account:

Speed from the user

The vehicle loading condition

Material properties

The pavement dimension

Rolling conditions

Vehicle speeds

Tire inflation pressures

Various applied loads

AC (Asphalt Concrete)

Exhibiting recoverable and irrecoverable deformations

Highly complex composite material

The different types of tires have different stresses at the pavement surface.

Reliable pavement responses

A accurate constituive relationschip of asphalt concrete

A realistic tire-pavement interface

Asphalt properties

influence of stiffness modulus and temperature to strain

the stiffness modulus of asphalt mix is significantly influenced by pavement temperatures

when the temperature changes from 25°c to 50°c

the asphalt strain will more than double

εv (275ms --> >600ms)

εr (80ms --> >180ms)

the stiffness will shall decrease 10 fold (3783 Mpa -->319.7Mpa)

elastic modulus

based on the recoverable strain under repeated loads

resilient modulus Mr

Mr= σd/εr

εr= the strain

σd= deviator stress

relationship between stiffness modulus and strain

The subgrade strain decreases as the asphalt thickness increases

Modulus and thickness of the pavement surface layer from SASW tests

Why use SASW?

-Up to 60m(!) deep

-Lot of different materials possible

-Quick results

-Non-destructive

How does SASW work?

Surface wave testing uses the dispersive characteristics of surface waves to determine the variation of the shear wave velocity (stiffness) of layered systems with depth.

Requirements for SASW

-The width between impact and each sensor limits the search dept (width = 1,5 or 2 x depth is rule of thumb)

-Flat surface

What is an SASW test?

"Spectral Analysis

of Surface Waves" test

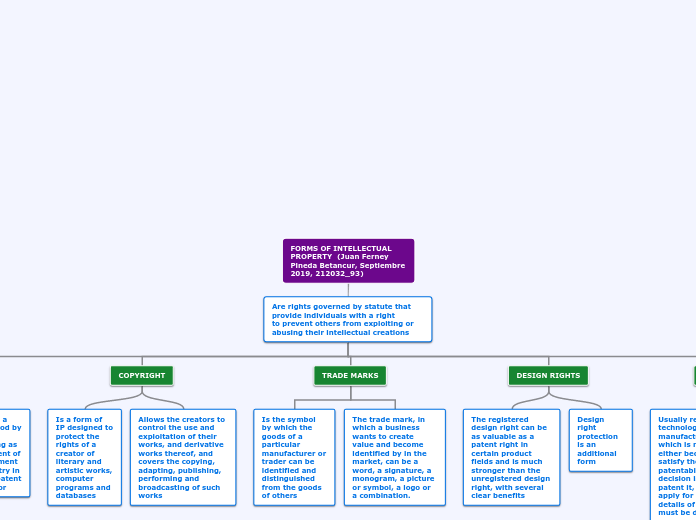

Difference Rigid pavement VS Flexible Pavement

Cost

Maintenace cost

Initial Cost

Less

More

composition

Binder ---> Bitumen

Binder ---> Cement

surface course

base course

subbase course

subgrade

Joints

Laid constantly ---> no joints

constructed in bays ---> joints needed

Lifespan

15 years

30 years

Curing Time

24 hours

Layers

multiple layers

casted as 1 slab

The effects of perpetual desing and Implementation of empirical pavement analysis. Bron [Artikel 1 J.P]

The benefits and the disaventige of perpetual design

Benefits

Perpetual paving avoids overstressing

The performance against surface distresses.

The initial cost are 20% higher than in other types of pavement

The granular materials are used for conventional designs

Influence of the asphalt layer on track information and rate of rutting

The best pavement is with a asphalt layer of 300 mm thickness

Below a thickness of 180 mm

The thickness has a clear effect on the rate of rutting

Test

Thin asphalt layers (80mm)

Always full-depth cracking in the hole layer

Thicker asphalt layers (290mm)

Only 28% of the sections showed cracking and that was confined to the top layers

Possible problems that needs to be considerd

Life-cycle cost analysis

International roughnes index

Total rutting depth

Alligator cracking

Longitudinal cracking

Use of the cement stabilised base

Perpetual pavement

Flexible-composite

Different materials for pavement are based on

Climate => different effects on the pavement analyse

The circumstances

The load

The country

The climate