Metal Removal Process

By:- Shivam Naik

Anilkumar Patel

Aashish Sharmaundefined

Types of Technologies

Welding/Buring Technologies

Oxy-Fuel Welding

Process of welding or cutting metal workpice by means of fuel gases or oxygen.

Types of torches

Rose bud torch

Primarily used to heat materials to allow bending and straightnening.

Welding torch

Allows us to weld several materials, cracks and major fracturs in the metals. It consist of two pipes containg gaseoues fuels which are used to weld materials.

Injector torch

Consist of an oxygen flow with two gaseous fuels through the venturi effect along which allows to maintain an equilibriium between the amount of oxygen and gaseous fuels in the flow.

Cutting torch

Allows us to cut several materials. It consist of three pipes containg gaseoues fuels and an oxygen trigger which is used to cut materials.Element is preheated so as oxygen blast trigger is conducted, oxygen react with themetal forming metal oxides, reducing its strength and thereby cutting the worpiece.

Types of Fuels

Methylacetylene propadine gas (MPS) and MAPP

Butane, Propane and Propylene

Acetylene

Hydrogen

Gasoline

Plasma

Process of generating a direct flow of plasma from plasma jet which can be used for plasma cutting, sparying and plasma waste treatments. Plasma cutter generate high temperature and hence they are useful in generating thin and thick dimensions.

Laser

A Process of emmiting light through several loptical amplifiers on the metal surface primarily used for preciously cutting complex workpieces.

It mainly conists of stimulated emission of photon flow with certaing frequency,polarizationa and phase.

Machine Technologies

Broaching

Consist of toothed tool whcih is moved againsts the surface of workpiece. It allows better surfaces and dimensions

Types of Broaching Process

Surface Broaching

Methods consist of reciprocation of broachagainst the surface of the materials.

Internal Broaches

Method consist of broaching the internal surface of the holes in the workpiece

Rotary Broaching

Consist of roataing broach over the surface of the materials. It allows to construct complex and irregular holes over the surfaces without using broachnig machine.

Sawing

Circular saw

Roatating cutting balde used over workpiece

Band saw

Consist of a saw blade moving in continous loop over the workpiece

Hacksaw

Linear reciprocation of the blade over the workpiece

by a hydraulic drive frame.

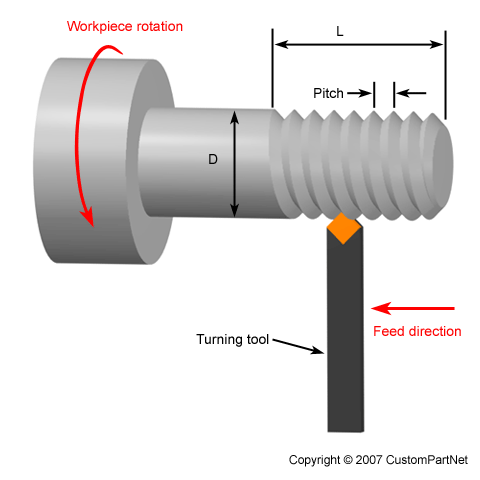

Turning

Types of Cuts

Contour Turing

A turinng process which consist of rotating metal part with a cutting tool following a contour path on the metal surface formig contour.

Chamfering

Consist of a Metal part rotated aginst a cuting tool with a sharp edge, cutting the surface at an angle causing a formation of a chamfer.

Threading

Consist of rotating metal part against the Pointed cuttng tool held parallel to the rotational axis causing threads in the work piece.

Facing

A method of rotating a metal part with a cutting tool held perpendicular to the rotational axis of the workpiece.

Cut Off

Radially holding a cutting tool to cut out the a part of the rotating workpiece

Workholding Method

Centre Drive

Face Plate

Chucks

Collet

Drilling

A method of contructing a holes with variable diameters, depths and shapes

Types of Processes

Deep hole Drilling

Conists of drawing holes with depth five times grreater than the diameter of the holes

Centre Drilling

Constructs a mark which represent the axis of rotation for the workpiece

Spot Drilliing

Constructs a hole as a mark which act as guide to conduct further drilling on the particularspot

Microdrilling

Conduct a process of drilling holes with diameter of less than 0.5mm

Gun Drilling

Consist of a special kind of cutting fluid compressed through the hollow structure of drill bit to the cutting metal surface.

Allows to drill hole with higher depth to diameter ratio.

Types of gun drilling

External chip removal type

Internal chip removal type

Trepanning

Allows to drill larger holes, whihc is usefull in making groves, and O rings.

Types of holes

Counter Boring

Through Holes

Blind holes

Reaming

Tapping

Milliing

A cutting process which consist of a milling cutter with mulitiple cutting edges held perpendincular to the direction of the workpiece fedding, which allows us to develop a planar surface, slots, grooves, and certain dimensional profiles

Types of milling processes

Peripheral Milling

A method which consist of axis of rotation of a milling cutter parallele to the workpiece feed. The proximity of the milling cutter teeth are at the periphery of the milling surface.

Types of Peripheral milling

Slab milling

Consist of a milling cutter with a width larger than the periphery of the workpiece. Allows to create a planar surface on the workpiece.

End milling

Consist of a cutting tool held vertically to the milling surface

with its diameter less than the width of workpiece causing a

slot in the part

Types of end milling

Pocket milling

Consist of a cutting tool creating a shallow feature

with certain depth.

Profile milling

Consist of rotating tool cutting on the periphery

of the workpiece.

Slotting

Consist of a milling cutter with a width smaller than the periphery of the workpiece. Allows to create a slots on the workpiece.

Face Milling

A process of milling consist of rotational axis of milling cutter perpendicular to the milling surface.

Types of face milling

Conventional Face milling

Surface countering

Consist of a cutting tool with a curved edge, which follows a curved path on the milling surface constructing a contour on the workpiece.

Types of milling machine

Ram type mill

Spindle can be allinged in both vertical and horizontal position

C-frame mill

Consist of more powerful hydraulic drive motors for integral power feeds

Column mill

Bench mounted mills

Turrent Mill

Spindle can be allinged at several posistion

Floor mill

Consist of a rotary table and horizontal running spindle parallel to the table

Bed mill

A conventional type of mill use in a industries

Mill Orientation

Horizontal mill

Consist of the rotational axis of cutting tool held horizontal

Vertical mill

Consist of the rotational axis of cutting tool held vertical

Boring

Consist of cutting the internal features of the drilled workpiece.

Types of Boring

Back Boring

Line boring

Erosion Technologies

Electric Discharge Machining (EDM)

A method of removing a part of the materials by conducting a a series of sub sequently occuring discharge (spark) on the workpiece. This process requires two electrodes seperated by a dielectric liquid which consist of intense electric fields.

Types of Process

Sinker (EDM)

Consist of workpiece and a electrode tool connected to a power supply which acts as anode and cathode in the system respectively. Dielectric fluid in the system act as ionizing channel which generates sparks as the apower supply is passed through in the operating system.

Wire (EDM)

A process of a drawing wire slowly on the surafce of the workpiece with a predetermined path. The system consist of a dielectric fluid between the wire and the workpiece acting as a plasmic channel in the gap developing million sparks per second. This Process allows to cut the workpiece with high thickness and construct most complicated structure preciously.

Water Jet

A process of removal of material by means of water jets running water at high velocity on the material workpiece.

Manual Technologies

Chisel

Shear

Snip

Saw

Final Product to be extracted

Design of the final product

Dimensional Accuracy

Length,Width,Height,Weight,Volume and Area

of the material to be extracted.

Internal and external thickness of the holes,

and pocket profiles

Limits and allowance

Complex profiles

Surface finishing

Clearance

Tolerance

Fittings

Edges

Material Requirements

Metal: Ferrous and non ferrous

Non-metals

Ceramics

Polymers

Alloys

Wood

Cutting Parameters

Design of the cutting Tool

Precise geometry according to product

requirements

Diameter to Depth Ratio

Radial Depths

Sharp Edges

Axial depths

Cutting Speed

Drill speed

Saw speed

Roational

Linear Reciprocating

Circular Loop

Milling Cutter speed

Water Jet speed

Broach Speed

Cutting feed

Reciprocating Feed

Feeds of workpiece in milling, drilling

Boring and Broaching operations

Roational Feed

Feeds of workpiece in turining operations

Cutting fluids

Required chemical properties

Higher visconsity

Lubricator

Fluid Film

Collant

Types of cutting fluids

Glysol-Water Emulsion

Water-Oil emulsions

Aerosal

Pastes

Gels

Oil

Machinability

Ease of chip disposal

Better Mechanical Properties

Thermal Stability

Surface Finshing

Strength

Ductility

Tool Life

Force and Power exerted on the Tool

Cutting temperature

Cutting speed

Tool wear

Crater Wear

Flank wear

Edge Wear

Tooling

Turining process requirements

Angle and sizes of cutting tool

Angle of cutting tool

Cutting edge angle

Nose radius angle

Side Rand angle

Relief angle

Rank angle

Sizes of Cutting tool

Square Shape

V- Shape

Workhold method tolling

Drive Centre

Face Plate

Chuck

Jawed chuks

Seld Centering

Independent Jaw

Drill Chuck

Electrostatic

Magnetic

Ferrous

Collet

Milling process requirements

Horizontal Milling cutters

Staggered Tooth

Form Relieved

Double angle

Helical

Vertical milling cutters

Flate End

Chamfer

Ball End

Reamer

Twist

Face

Tap

EDM Requirements

Sinker EDM

EDM fluid and filters

Orbiting cut system

Electrode Holder

Rotating Spindle

Magnetic Chuck

Wire EDM

Cleanre and Filters

Dielectric fluids

EDM wires

Machining

AutoCAD and 3D mechincal CAD softwares

Computer-Aided Design (CAM)

CNC drive operation

Direct Numerical Control (DNC) drives

Allows to network several CNC machines

operating in sequence. It provides larger

memory space in the control and can

transfer the amount of data to each operating

CNC system in a manufacturing process

Design for Manufacturablity (DFM) drives

Alllows to fix design flaws in the CNC operations

Milling machines

Base and columes

Table

Saddle

Knee

Lathe Machines

Head Stock

Lock Knob

Tail Stock

Tool Rest

Spindle

Centre

Revolving centre

Spring centre

Drive Centre

Dead Centre

Soft Centre

Pipe centre

Cup centre

Bed

Drill Presses

Gear Head Drill Press

Radial arm drill press

Mill Press

Costs

Material Costs

Shape and size of the stock

Quantity of stock per unit

Method of cutting

Production Costs

Time required for production

Total Production of stocks

Total replacement time

Set up time

Load time

Cut time

Idle time

Mainatainece Costs

Inspection of the cutting tools, machines, equipments and accessiories

Team management

Cleaning

Tolliing costs

Number of cutting tools required for the operations

Cutting speed

Life time of tools

Cutting speed

Cuttnig time

Posibilities of defects

Programming errors in CNC,DNC and DFM's

Defect in the machines, tooling

and equipments

Minor fractures in the face plates,chucks,collets

and drives.

Disallingment of rotaional axis of the cutters

Incorrect positioning of the workpiece

Errors in the design Structure

Incorrect cutting Parameters

Defective cutters

Human Errors