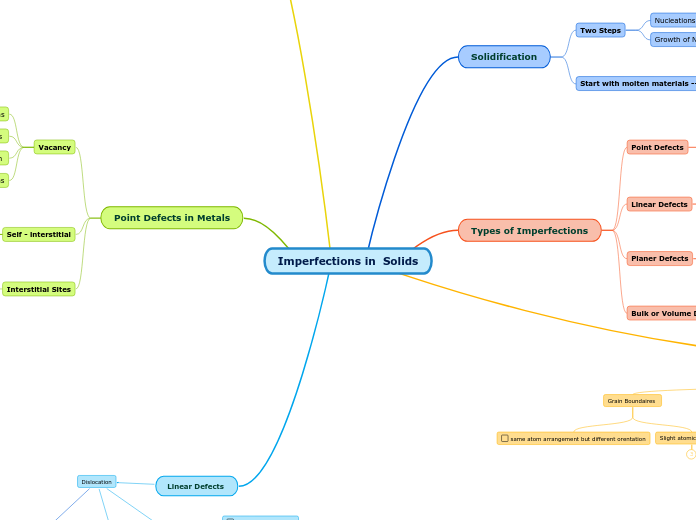

Imperfections in Solids

Solidification

Two Steps

Nucleations

Growth of Nuclei

Start with molten materials --- All liquid

Nuclei

Crystal growing

Grain Structure

Types of Imperfections

Point Defects

Involves 1 or 2 atomic/ionic positions

Vacancies; Interstitial; Atoms; Substitutional; Impurity Atoms

Linear Defects

Some atoms are misaligned; Occur along a line only

Edge/Screw/Mixed Dislocations

Planer Defects

Boundaries or planes separate a materials into region

Grain Boundaries; Twain Boundaries; Stacking Faults

Bulk or Volume Defects

Introduced during fabrication processes

Cracks; Pores; Voids; Precipitates; Foreign Inclusions

Planer Defecs

Grain Boundaires

same atom arrangement but different orentation

Slight atomic Disorder

Twain Boundaries

mirror reflections of atoms position across twin planes

Found in FCC(annealing) and BCC or HCP(mechanical0

Stacking

Found in FCC metal

Occur when errors present in the planer stacking sequence

Impurities in Metals

Metal Alloy

Mixture of a metal and a non-metal

can include multi-phase mixtures

Have enhanced properties

Solid Solutions

Substitutional Solid Solutions

Increase the strenght of metallics materials

Replace host ones in lattice sites

Different sizes disturb surronding crystal structures

Number of defects is independent of temperatures

Interstitial solid solutions

Extra atoms/ions placed in normally unoccupied positions

Impurity latoms smaller than hosts

max concentration of impurity is < 10%

Number of atoms remains constant with temperature

Point Defects in Metals

Vacancy

Result from missing atoms

Found in all crystalline materials

Computation of Equilibrium Concentration

Exchange position with neighboring atoms

Self - interstitial

Host atoms are crowded into interstitial sites

Found in crystal structures having low packing factor

Not occur naturally

Exist in very small concentrations

Interstitial Sites

Both FCC and BCC are octahedral and Tetrahedral

BCC Tetrahedral Sites

4* 1/2* 6 = 12 tetrahedral sites/cells

24 face sties

BCC Octahedral :

6 face-center sites & 12 edges sites

1/2* 6 + 1/4 *12 = 6 Octahedral sites/cell

Linear Defects

Dislocation

Screw

Form by shear stress

Burgers Vector : b

perpendicular to dislocation line slip direction

parallel to screw dislocation

Edge

Burgers Vecter : b

Perpendicular to edge dislocation, parallel to line slip dislocation

Shows atom slip, magnitude, and direction

Mixed Dislocation

Dislocation alters direction

Permanent Deformation

Move when stresses applied

Burgers stay constant

Nv= N exp = (-Qv/KT)