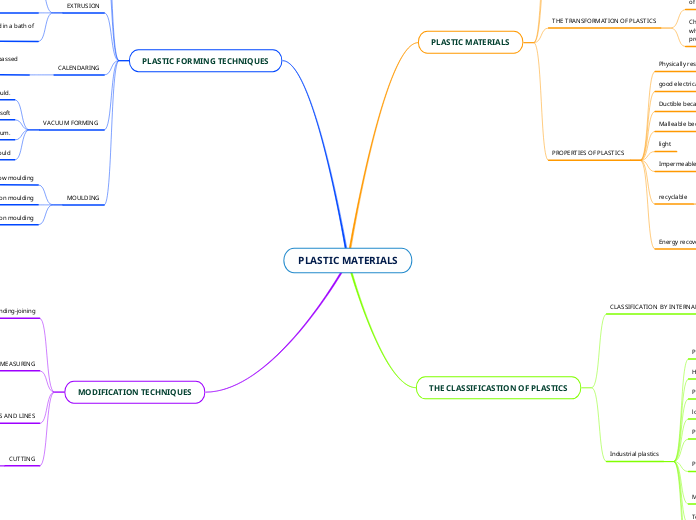

PLASTIC MATERIALS

PLASTIC MATERIALS

Consists of long chains of molecules, mostly made of the element carbon

THE ORIGIN OF PLASTICS

NATURAL PLASTICS

SYNTHETIC PLASTICS

THE TRANSFORMATION OF PLASTICS

During the manufacturing process, fillers may be added to reduce the cost of production and enhance certain properties of the raw materials

Chemical additives can aslso be used, such as plasticizers which increase the flexibility and the resistance of the final product.

PROPERTIES OF PLASTICS

Physically resistant

good electrical, thermal and acoustic insulators

Ductible because they can be pulled to make theads

Malleable because they can be pressed into the sheets

light

Impermeable

recyclable

Chemical recycling

mechanical recycling

Energy recovery

Non-biodegradable plastic

biodegradable plastic

THE CLASSIFICASTION OF PLASTICS

CLASSIFICATION BY INTERNAL STRUCTURE

Thermoplastics

Thermosetting plastics

Elastomers

Industrial plastics

Polyethylene terephthalate

High-density polyethylene

Polyvinyl chloride

low-density polyethylene

Polypropylene

Polystryrene

Moulded

Expanded

Methacrylate

Teflon

Cellophane

Nylon

PLASTIC FORMING TECHNIQUES

Plastics products are typically made from powder, pallets, or resins.

Various techniques can be used to form plastic products, but the most important ones are extrusion, calendaring, vacuum forming and moulding

EXTRUSION

Thermoplastic material, usually in the form of pallets, is added to an extursion machine

Inside the cylinder, there is a screw that turns and pushes and pushes the plastic out through a die.

When the plastic leaves the machine, it is hardened in a bath of cool water

CALENDARING

In the calendering process, thermoplastic material is passed betwween rollers to make thin sheets.

VACUUM FORMING

A sheet of thermoplastic material is placed over a mould.

The sheet of plastic is heated until it becomes soft

The air under the sheet is sucked out to create a vacuum.

The sheet is cooled and removed from the mould

MOULDING

Blow moulding

Injection moulding

Compression moulding

MODIFICATION TECHNIQUES

measuring-marking-cutting-drilling-filling and sanding-joining

MEASURING

Carpenter´s square

measuring tape

ruler

Protactor

DRAWING MARKS AND LINES

CUTTING

Scissors

HACKSAW

utility knife