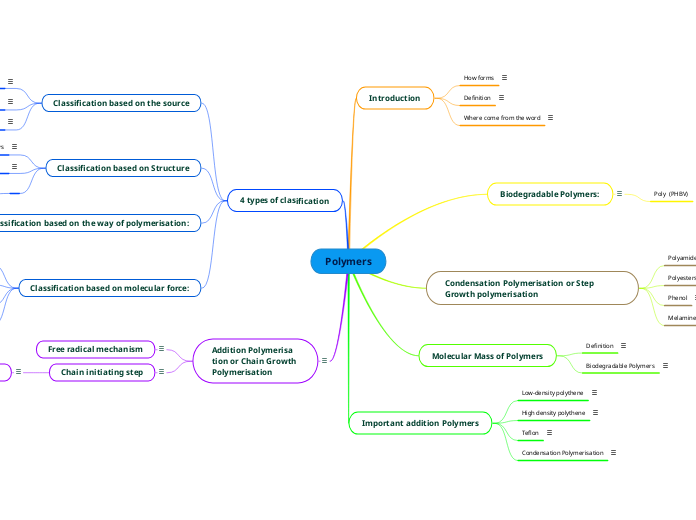

Polymers

Introduction

How forms

Are formed by joining of repeating structural units on a large scale.

Definition

Is any of a class of natural or synthetic substances that have really large molecules, formed by smaller molecules called monomers, that are joined toguere by something called covalent bond.polymer | Description, Examples, Types, Material, Uses, & Facts. (s. f.). Encyclopedia Britannica. https://www.britannica.com/science/polymer

Where come from the word

The word ‘polymer’ is coined from two Greek words: poly means many and mer means unit or part.

Biodegradable Polymers:

A large number of polymers are quite resistant to the environmental degradation processes and are thus responsible for the accumulation of polymeric solid waste materials.

Poly (PHBV)

It is obtained by the copolymerisation of 3-hydroxybutanoic acid and 3 - hydroxypentanoic acid. PHBV is used in speciality packaging, orthopaedic devices and in controlled release of drugs. PHBV undergoes bacterial degradation in the environment.

Condensation Polymerisation or Step Growth polymerisation

Polyamides

These polymers possessing amide linkages are important examples of synthetic fibres and are termed as nylons. The general method of preparation consists of the condensation polymerisation of diamines with dicarboxylic acids and also of amino acids and their lactams.

Polyesters

These are the polycondensation products of dicarboxylic acids and diols. Dacron or terylene is the best known example of polyesters. It is manufactured by heating a mixture of ethylene glycol and terephthalic acid at 420 to 460 K in the presence of zinc acetate antimony trioxide catalyst as per the reaction given earlier

Phenol

Phenol - formaldehyde polymers are the oldest synthetic polymers. These are obtained by the condensation reaction of phenol with formaldehyde in the presence of either an acid or a base catalyst.

Melamine

Melamine formaldehyde polymer is formed by the condensation polymerisation of melamine and formaldehyde.

Molecular Mass of Polymers

Definition

A polymer's molecular weight is the sum of the atomic weights of individual atoms that comprise a molecule.https://www.sciencedirect.com/topics/engineering/polymer-molecular-weight#:~:text=A%20polymer's%20molecular%20weight%20is,or%20distribution%20of%20molecular%20weights.

Biodegradable Polymers

Biodegradable polymers are defined as materials whose chemical and physical characteristics undergo deterioration and completely degrade when exposed to microorganisms, aerobic, and anaerobic processes.https://www.sciencedirect.com/topics/materials-science/biodegradable-polymer

Important addition Polymers

Low-density polythene

It is obtained by the polymerisation of ethene under high pressure of 1000 to 2000 atmospheres at a temperature of 350 K to 570 K in the presence of traces of dioxygen or a peroxide initiator.

High density polythene

It is formed when the addition polymerization of ethene takes place in a hydrocarbon solvent in the presence of a catalyst such as triethylaluminium and titanium tetrachloride (Ziegler-Natta catalyst) at a temperature of 333 K to 343 K and under a pressure of 6-7 atmospheres. It's used for manufacturing buckets, dustbins, bottles, pipes, etc.

Teflon

Teflon is manufactured by heating tetrafluoroethene with a free radical or persulphate catalyst at high pressures. It is chemically inert and resistant to attack by corrosive reagents. It is used in making oil seals and gaskets and also used for non – stick surface coated utensils.calvo lindo

Condensation Polymerisation

It is applied the division of two bi-functional monomers by condensation.

4 types of clasification

Classification based on the source

A variety of synthetic polymers as plastic (polythene), synthetic fibres (nylon 6,6) and synthetic rubbers (Buna - S) are examples of man made polymers extensively used in daily life as well as in industry.

Synthetic polymers

Semi-synthetic polymers

Cellulose derivatives as cellulose acetate (rayon) and cellulose nitrate.

Natural polymers

Are found in plants and animals.

Classification based on Structure

Linear polymers

These polymers consist of long and straight chains.

These polymers contain linear chains having some branches, e.g., low density polythene

Branched Chain Polymers

Cross-Linked or Network Polymers

These are usually formed from bi-functional and tri-functional monomers and contain strong covalent bonds between various linear polymer chains

Classification based on the way of polymerisation:

Addition polymers

The addition polymers are formed by the repeated addition ofmonomer molecules possessing double or triple bonds.

Condensation Polymers

polymers are formed by repeated condensation the reaction between two different bi-functional or tri-functional monomeric units.In this reaction the elimination of small molecules such as water, alcohol, hydrogen chloride

Classification based on molecular force:

Elastomers

These are rubber – like solids with elastic properties. The polymer chains are held together by the weakest intermolecular forces in these elastomeric polymers. These weak binding forces permit the polymer to be stretched.

Fibers

Fibers are thread-forming solids that possess high tensile strength and high modulus. These characteristics can be attributed to the strong intermolecular forces like hydrogen bonding. These strong forces also lead to close packing of chains and thus impart crystalline nature.Ex:polyamides (nylon 6, 6)

Thermoplastic

These are the linear or slightly branched long chain molecules capable of repeatedly softening on heating and hardening on cooling. These polymers possess intermolecular forces of attraction intermediate between elastomers and fibres.Ex:polythene

Thermosetting

These polymers are cross linked or heavily branched molecules, which on heating undergo extensive cross linking in moulds and again become infusible.

Addition Polymerisa

tion or Chain Growth

Polymerisation

In this type of polymerisation, the molecules of the same monomer or diferent monomers add together on a large scale to form a polymer.

Free radical mechanism

A variety of alkenes or dienes and their derivatives are polymerised in the presence of a free radical generating initiator (catalyst) like benzoyl peroxide, acetyl peroxide,tert-butyl peroxide, etc

Chain initiating step

As this radical reacts with another molecule of ethene, another bigger sized radical is formed.

Chain propagating step

at some stage the product radical thus formed reacts with another radical to form the polymerised product

Chain terminating step

For termination of the long chain, these free radicals can combine in different ways to form polythene