par Никита Шакирзянов Il y a 3 années

203

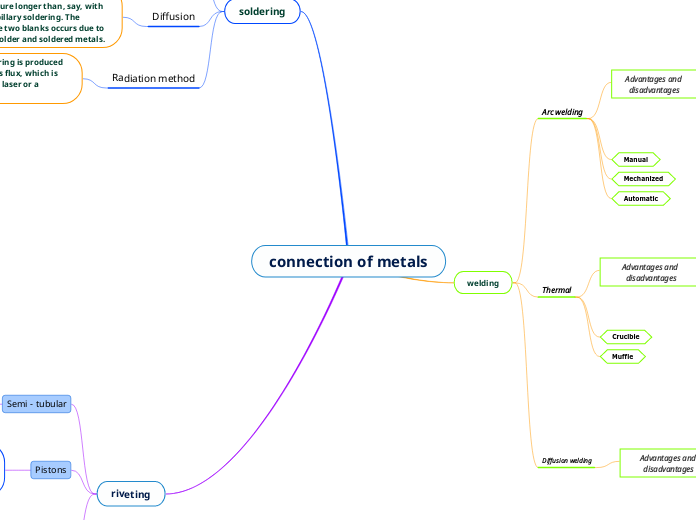

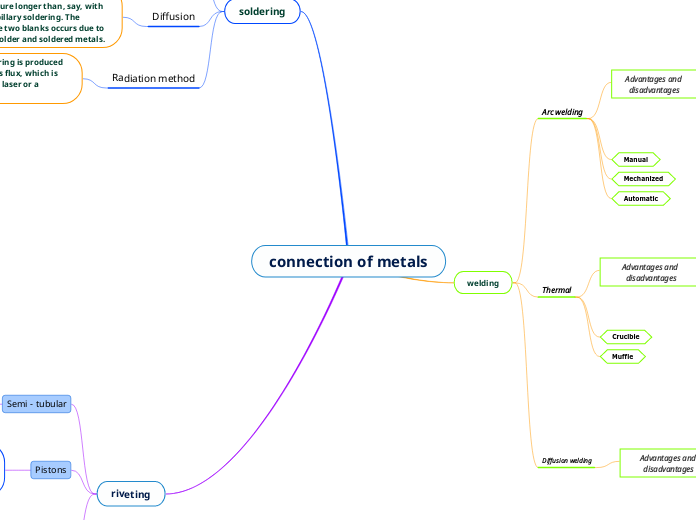

connection of metals

par Никита Шакирзянов Il y a 3 années

203

Plus de détails

+ to combine homogeneous and heterogeneous solids; + avoid deformation of parts; + do not use consumables in the form of solders and fluxes; + get waste-free production; + receive any area of the contact connection zone, limited only by the possibility of equipment; + ensure reliable electrical contact - the need to use specific expensive equipment; - the requirement to have special knowledge, skills and understanding of the work process; - time spent on thorough pre-processing of workpieces; - the difficulty of checking the quality of the seam without the need for its destruction.

+ excellent joint strength indicators. + low labor intensity of work. + low cost. + minimum metal consumption. - irregularities on the surface of the workpiece and the presence of an oxide film significantly impairs the quality of the joint. - thermal welding is possible only with metals that are close in terms of refractoriness

+ does not require complex training; + high process performance; + low cost of consumables (welding electrodes); + the simplicity of the process makes it easy to automate and mechanize it; + a small area of surface heating. - binding to the power grid; - inability to work without current converters (rectifiers, inverters) and transformers; - the presence of a preliminary stage of preparation of the welded surfaces.