par qusyairi abas Il y a 5 années

489

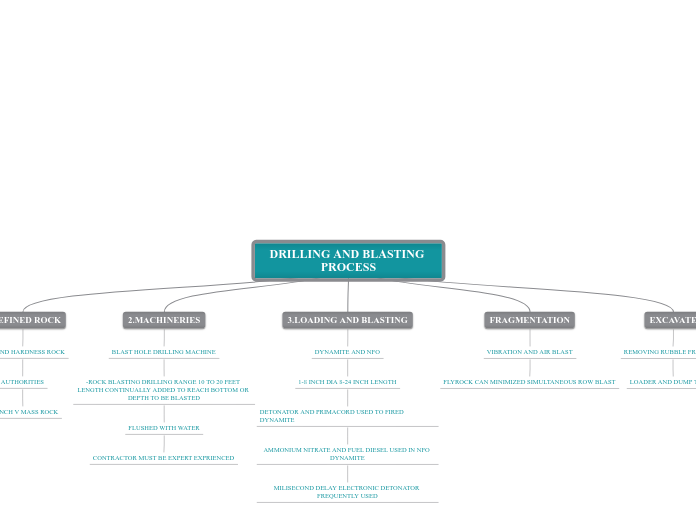

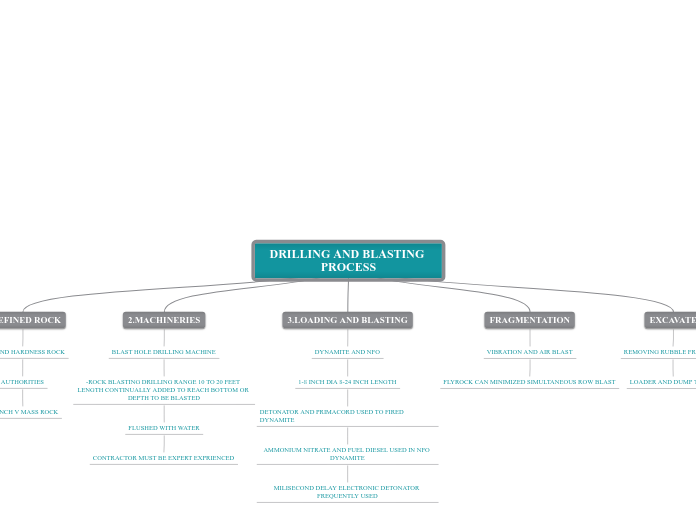

DRILLING AND BLASTING PROCESS

par qusyairi abas Il y a 5 années

489

Plus de détails

DETONATOR AND PRIMACORD USED TO FIRED DYNAMITE

AMMONIUM NITRATE AND FUEL DIESEL USED IN NFO DYNAMITE

MILISECOND DELAY ELECTRONIC DETONATOR FREQUENTLY USED

FLUSHED WITH WATER

CONTRACTOR MUST BE EXPERT EXPRIENCED

TRENCH V MASS ROCK