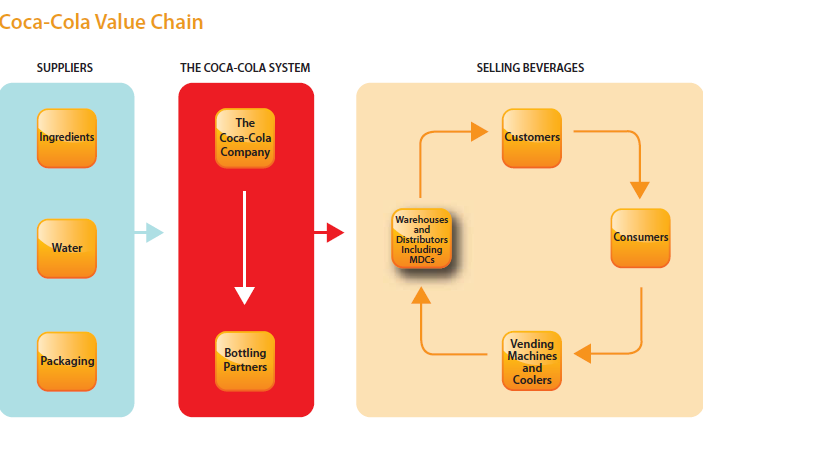

SUPPLIERS

FRANCHISE MODEL

LOCAL SOURCING OF SUPPLIERS KEEPS THE SUPPLY CHAIN SHORT AND FAST - HELPS TO KEEP UP WITH DEMAND

Coca Cola HELLENIC BOTTLING COMPANY

SUSTAINABILITY

PLANT BOTTLE PACKAGING

SUSTAINABLE PACKAGING

TOTAL QUALITY MANAGEMENT

MATCHING SUPPLY AND DEMAND

Coca-Cola works with its customers in what it calls “brand, pack, price, channel architecture,” determining what packages to order, what equipment to use and what service requirements will deliver the picture of success the client has in mind. “How you serve a hypermarket such as Carrefour or Wal-Mart is quite different to how you service a mom and pop in a rural area,” Buffington says. “Our supply chain starts at the shelf, and with customer service design, that is how we’re demand-driven. Planning supply is driven by forecasted customer demand input, seasonality and also by promotions or changes in merchandising in the store.”

Coke’s new mobile app allows proprietors to send order requests to local distributors, who then bid on the deal. A price is then promised along with a certain time frame for delivery, ranging from 45 minutes to 4 hours, compared to two or three days by traditional methods.

Coca Cola segments its supply chains in order to better match demand. The key reason for this is that each locality has different needs and customer preferences which then requires a different supply chain; for example an area that requires refrigerated distribution, has very different supply chain than an ambient type of product. Segmentation allows Coca-Cola to understand and implement best practices and meet its customers’ requirements in relation to their individual portfolios.

OPERATIONAL INNOVATION

Coca Cola's Recent Innovations

CUSTOMER EXPERIENCE MANAGEMENT

SMART LABEL

SIP AND SCAN

MASS CUSTOMISATION

FREE STYLE MACHINE

FREESTYLE MIXING

SHARE A COKE

Mass Customisation at Coca Cola both enhances the customer experience by making consumers feel more connected to the brand and product; as well as giving Coca Cola access to a wealth of customer data regarding preferences, locations, consumption patterns etc. that they can then use to further enhance customer experience and bring out new products in the future.

KEY TAKEAWAYS AND TRIPLE A

Coca Cola has implemented and deployed several strategies in creating innovative products, enhancing customer experience and improving efficiency throughout their operations around the world. I will now present you with my Key Takeaways through the Triple A Supply Chain.

AGILITY:

Agility is built in through mechanisms that continually match supply and demand such as the app.

Additionally, having a wide supplier network with local operations first minimises the chance that something goes wrong, but also allows for backup in case of any shocks.

ADAPTABILITY:

Building up a diverse supplier network builds adaptability to the various supply chains, as it allows Coca Cola to deal with any shocks due to expansive networks

ALIGNMENT

Coca Cola's Supplier Guiding Principles ensures that all of their partners align not only culturally but logistically - therefore maximising supply chain performance.