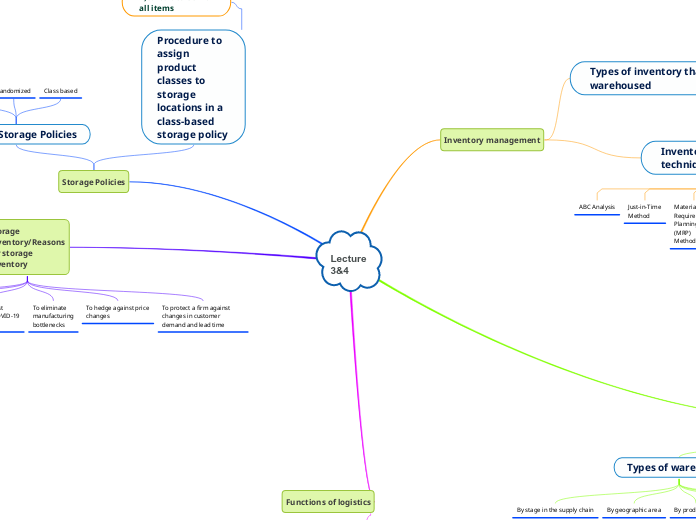

Lecture 3&4

Inventory management

Types of inventory that can be warehoused

Cycle stock

Safety stock

Transit inventory or pipeline inventory

Speculative stock

Seasonal stock

Dead stock

Inventory management techniques

ABC Analysis

Just-in-Time

Method

Material

Requirements

Planning

(MRP)

Method

Economic

Order

Quantity

(EOQ) Model

Minimum

Safety Stocks

VED Analysis

Fast, Slow

and Nonmoving

method

Warehouses

Types of warehouses

By stage in the supply chain

By geographic area

By product type

By function

By area

By systems

Flow of material in warehouse

1)Receiving: Goods

2)Inspection and quality control

3)Preparation for transportation

4)Put away

5)Order picking

6)Aggregation of

SKUs

7)Prepration for

transportation

8)Transportation

Order picking

Order-Picking Methods

Storage Policies

Types of Storage Policies

Dedicated

Randomized

Class based

Procedure to assign product classes to storage locations in a class-based storage policy

1)Calculate COI for

all items

2)Sort items in a

nondecreasing

order by their

COIs

3)Allocate the first

item in the list to

the storage

spaces that are

nearest to the

input-output

Storage Inventory/Reasons for storage

inventory

To take advantage of

economies of scale

when purchasing,

transporting and

To balance supply and

demand (to answer

demand as needed)

To hedge against

strikes, fires, COVID-19

etc

To eliminate

manufacturing

bottlenecks

To hedge against price

changes

To protect a firm against changes in customer demand and lead time

Functions of logistics

1. Order

processing

2. Inventory

control

3. Warehousing

4. Transportation

5. Material

handling and

storage

6. Logistical

packaging

7. Information