Gum and Stabilizers

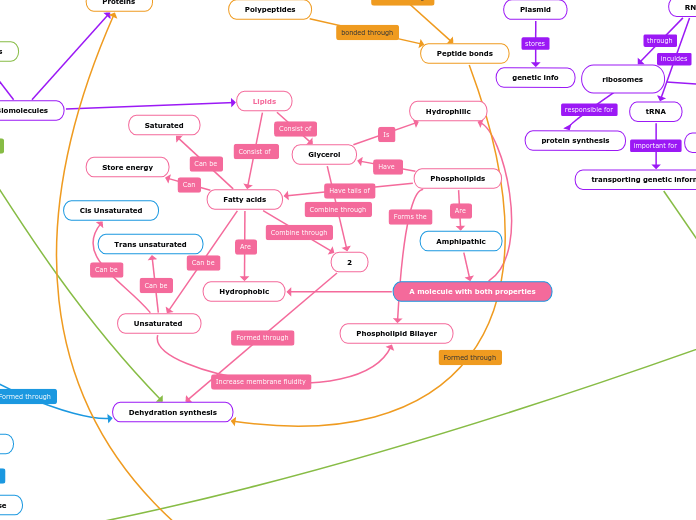

-A range of polysaccharides and protein.

-Usage level <2%

Types of hydrocolloids

Cellulose derivates

Batter

-Retard loss of moisture and improve adhesion

Fried foods

-Create a barrier to oil absorptio

Functions:

-thickening, suspending, stabilizing & modify flow characteristics

Optimum pH range: 4-10

Chemically modified cellulose into carboxymethylcellulose (CMC), hydroxypropylmethycellulose (HPMC) and methylcellulose (MC)

Xanthan gum

Functions:

-Thickening, suspending, and stabilizing effect

Optimum pH range: 1-13

Optimum soluble solids range: 0-80%

Solubility in water: soluble in cold and hot water

Gelling conditione: Gel at temperature below setting temperature

Polysaccharides produced from fermentation of CHO substrate with xanthomonas campestris.

Guar gum

Functions:

-Viscosity binder

-Stabilizer and water binder

Optimum pH range: 4-10

Optimum soluble solids range: 0-80%

Solubility in water: Soluble in both hot and cold water

Gelling conditions: Non-gelling

A linear chain of mannose with single galactose units attached as side chains.

Locust bean gum (LBG)

Meats

-Act as binder

Dairy products (such as ice cream)

-it protects against heat shock and imparts a desirable mouthfeel.

Optimum pH range: 4-10

Optimum soluble solids range: 0-80%

Does not form gel by itself, but can form gel when combined with xanthan gum.

Insoluble in cold water and must be heated to dissolve. The maximum viscosity develop when heated to 95C, then cooled.

Gum arabic

Soft drink emulsion

-As an emulsifier & stabilizer

Beverages such as beer

-promote the stabilization of foam

Volatile flavour compounds

-Act as encapsulation agent to encapsulate the volatile flavour

Confectionery products

-to retard sugar crystallisation and promote emulsification

Least viscous & most soluble

Dissolve easily in hot and cold water

Alginate

Applications

Emulsion like mayonnaise

-stabilizer in emulsion (Propylene glycol alginate)

Beverages

-As thickener & stabilizer

Ice cream

-to avoid crystallisation

Can form gel in cold water with the presence of Ca ion, and the gel is thermo-irreversible.

Made up of blocks of D-mannuronic acid & L-gluronic acid

Carrageenan

Applications:

a) Water dessert gel: Kappa+ Iota

b) Chocolate milk: Kappa, Lambda

c) Canned & processed meats: Kappa

Calcium and potassium ion can form bridges between adjacent double helices through an electrostatic binding to two adjacent sulfate groups, thus stabilizing the network.

Can be divided into:

a) Kappa carrageenan

-Able to form thermoreversible gel

b) Iota carrageenan

-Able to form thermoreversible gel

c) Lambda carrageenan

-Non-gelling

Composed of linear galactan polysaccharides with sulphate content of 15-40%

Pectin

Low methoxy pectin (LMP)

Can be further divided into:

a) Conventional low methoxyl pectin (LMP)

b) Amidated low methoxyl pectin (ALMP)

To form gel:

a) Soluble solid content: 0-80%

b) pH: 2.5-5.5

c) Presence of calcium ion

Heat reversible

DE<50%

High methoxy pectin (HMP)

Applications:

a) Jam with suspended fruits

b) Acid fruits

Can be further divided into:

a) Extra rapid set

b) Rapid set

c) Medium set

d) Slow set

Firm and short structure, clear and transparent, excellent flavour release

To form gel:

a) Soluble solid content: 55-85%

b) pH: 2.8-3.8

Not heat reversible

DE > 50%

Sources of hydrocolloids

Pectin: Peel of citrus fruits or apple pomace

Konjac glucomannan: Armophophallus konjac, K. Koch tuber

Locust bean gum: Seed of carob bean

Carrageenan: Seaweeds

Gum arabic: Acacia senegal L

Functions

Secondary Functions

Formation of film

Encapsulation

Control of crystallisation

Suspension of particulates

Stabilisation of emulsion

Primary Function

Gelling agents

Thickening agents

Factors which affect gum properties

Distribution of side chains

Number of side chains

Type of side chains

Monosaccharide composition

Molecular weight