Since a young kid, I have always been interested in cars. Moreover, I have followed closely Tesla's development since their entry in the automative industry. Tesla is the disruptive actor in this industry because they have creating full electric cars as well as they have added so many technology in their cars (i.e., self driving cars).Besides, after dealing with 2 business case about car manufacturing companies (Toyota and BMW) I feel that I could discover the O&SCM inside a disruptive company in this mature industry and the how Tesla does it differently.

References

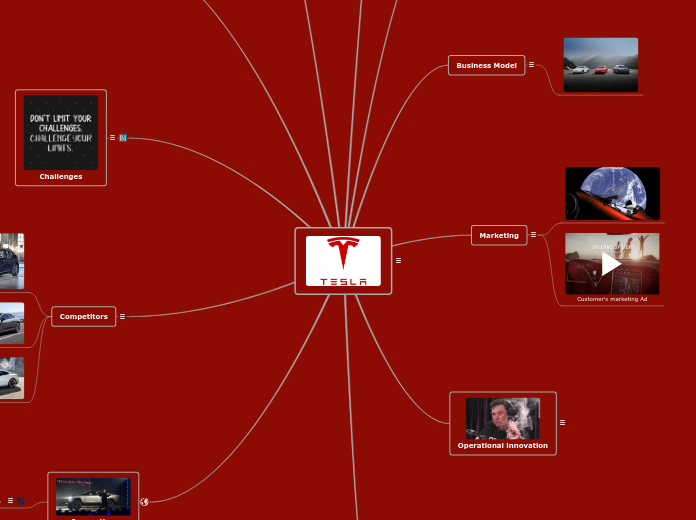

to construct my MindMap on Tesla,I have used different articles and videos on internet, which are:How Tesla Model S is made:https://www.youtube.com/watch?v=8_lfxPI5ObMBCG Top 10 innovative companies in 2019:https://www.teslarati.com/tesla-most-innovative-companies-in-2019-ranking/ https://electrek.co/2019/10/09/tesla-panasonic-relationship-hits-hard-times-tesla-make-own-batteries/https://www.businessinsider.com/brandenburg-berlin-germany-where-teslas-gigafactory-will-be-built-2019-11?IR=Thttps://www.industryweek.com/operations/article/22025252/tesla-vs-tps-seeking-the-soul-in-the-new-machinehttps://www.statista.com/statistics/314863/research-and-development-expenses-of-tesla/https://cleantechnica.com/2019/04/28/non-stop-engineering-innovation-are-the-lifeblood-of-tesla/https://electrek.co/2019/09/13/tesla-patent-battery-cell-better-performance-cheaper/http://panmore.com/tesla-motors-inc-operations-management-10-decisions-areas-productivityhttps://www.washingtonpost.com/technology/2019/11/01/federal-safety-officials-probe-alleged-tesla-battery-defects/https://www.procurehere.com/what-tesla-can-teach-us-about-procurement-best-practices/

History

Tesla was founded by Elon Musk in 2003 after seing that General Motors was unable to create their first full-electric vehicle.

Business Model

Tesla's business model was at the beginning to develop high-end all electric sports car at an expensive price.Today, they have developed economies of scale thanks to its new manufacturing process and the acquisition of a "gigafactory" to build their own batteries. Therefore, Tesla's is now building high-end cars at a different price range starting from $35,000 to more than $100,000.

Marketing

Operations and Marketing are related as both departments want to break down silos, which is the first step to be a customer centric organization. As we saw during Session 11, the 5C's model (Communication, Coordination, Cooperation, Confidence and Common and mutual knowledge) help to break down silos.Therefore, coordination and communication between Marketing & O&SCM (as well as other departments) are key for Tesla.This is where Tesla and Elon Musk's genius comes into place. Comparing with other car manufacturers, who spend hundreds of thousand (if not million) on advertising on TV, Tesla makes none!Tesla marketing strategy is first made on word-of-mouth. Also, Tesla's CEO, Elon Musk, is thanks to his twitter account the new type of Marketing director.In addition, Tesla doesn't spend a penny on advertisement but customers are making ads on YouTube for Tesla.

Customer's marketing Ad

Operational innovation

As we saw during Session 1, Operational Innovation means to re-think the way of working and it can be developed at any steps of the activities associated to O&SCM. In this part I will mention some Operational Innovation applied by TeslaTesla has a new way of taking orders compared to the rest of the industry. To order Tesla today, customers need to make a down payment (from $1,000 to $3,000) right after they have personalized their cars and agreed to terms of the company.Before, when someone wanted a car, they will sign a document and pay the car when it arrives. The customer could at least see the "real" car before paying anything. At Tesla, customers don't see their car but still pay for the manufacturing process to begin.The interesting thing here is that it doesn't stop customers to by new Tesla cars as the demand for cars is increasingIn terms of procurement, Tesla maybe owns the biggest building in the world (over 15 million square feet or 1,40 kilometers squared). Therefore, Tesla's goal is to provide enough batteries when the demand for it will increase.Starting with a sedan, Tesla has developed two other products, a more affordable car (the Model 3) and an SUV (the Model X). It doesn't here, the company has released two months ago, its new pickup (the Cybertruck) and want to create the first electric truck.Tesla has established very ambitious goals, but Elon Musk, the board of directors and investors believe that they will be able to reach their goals.

Recommendations & conclusion

Tesla has created an amazing company which is creative, innovative and sustainableTesla needs to reduce its cost per unit because competitors cars are less costly (it might decrease the demand for Tesla's cars).It has developed a strong employees confidence.Technology and innovation are one of their main strengthsTesla breaks down silos because of cooperation and sharing mutual knowledge. Elon Musk plays a substantial role in it.The company might want to invest in R&D for hydrogen cars (as company are devoting a great amount of their budget into R&D for hydrogen cars that could be an alternative to fuel cars)Tesla needs to continue with their strategy to remain the leader of Electric Vehicle's industryTesla has disrupted the automative industry with heavy investment in R&D and technology. They are now the leader in Electric Vehicles. The company thinks out of the box and is looking to the future. They want to create the car of the future, in terms of design (look at the picture of Tesla's Cybertruck in innovation, and compare it with another pick-up car) and in term of renewable development.

Manufacturing process

Tesla's cars, as nearly all the automative industry, is Make-to-order. This means that customers are able to design the vehicle and choose from a wide variety of options availableMoreover, when a customer order a car at Tesla, he or she has to give a down payment of $1,000 for the Model 3 (the price is much more for Model S & X).Customers can wait more than 18 months to get they car. This high waiting time was due supply chain delays. In the lean 6 sigma: Tesla's biggest waster was the wasted waiting time for the next step in the process.In the beginning, Panasonic supplied batteries to Tesla. As demand increased for the automative company, Panasonic was unable to meet this new demand and they also had quality problem within their batteries, which slowed down Panasonic manufacturing plant.

Other GigaFactory

Tesla has three Gigafactories, the most famous one in Nevada, another one in New York State and a third one in ShanghaiTesla is planning to open it fourth Gigafactory in Germany by the end of 2021. Here is an article about this new plant. It is very interesting to see how with this Gigafactory, Tesla will be able to reach better the European market with the creation of batteries and the next SUV of the company, the Model Y

Lean 6 sigma

To avoid the waiting time with its partnership with Panasonic, Tesla is planning to manufacture batteries itself.This could ensure Tesla to meet demand and would be able to increase their supply chain!Takt time

Just-in-time

For some materials that is not built by the company, such as some raw material, Tesla uses Just-In-Time manufacturing process. Therefore, as soon as materials arrive, employers and machines work directly on them to create work-in-progress inventory.

Takt time?

Does Tesla uses Takt time for the production of their cars?As a new company in the automative industry, people could believe that the electric company relies their production model on Ford's and Toyota's model, which is takt time (which comes from the German). Takt time is the pace a company should have to match demand.Nevertheless, Tesla is not using takt time as their reference while manufacturing their products. Right now, they are trying to have the quickest assembly line (while only being able to produce 7,000 Model 3 per week; a low number compared to the rest of the industry).

Triple-A supply chain

Agility: Tesla wants to increase their production to have the quickest assembly line. For the past years, they are reducing their numbers of suppliers and to develop most of their product by themselves, which makes them company more agile if they have to increase their production to catch up with a higher demandAdaptability: With the new Gigafactory in Germany, Tesla is able to spot new supply bases as well as increase they presence in Europe. Alignment: In terms of the Triple-A supply chain, Tesla doesn't have the alignment part. As Tesla constantly rebased patents regarding their batteries, they don't release informations regarding those products to their suppliers or competitors. In addition, Tesla has had a lot of delay in their production of the Model 3 and they didn't do any discounts to their customers.

Challenges

Challenges for Tesla are the following:Car manufacturers are starting to develop and introduce to the market their own electric vehicle. Companies such as Toyota, Audi, Mercedes invested (with their free cash flow) in R&D to build their own car of the future. Therefore, it could curb Tesla's demand.Hydrogen cars might be the new trend in a near future. Hydrogen is a 100% renewable energy that could be used instead of petrol. Therefore, Tesla needs to do something about those two challenges, if not, it could curb its demand.

Competitors

By disrupting the automative industry thanks to innovation in Electric Vehicles, Tesla has created a Blue Ocean. Nevertheless, it might transform into a Red Ocean as competitors are investing heavily in electric cars and are gaining market shares in this particular segment. But, as of today, Tesla has still a competitive advantage due to their innovation and operations efficiency.Tesla's competitors are all car manufacturers that are heavily investing in Electric Vehicle (EV). In the market in terms of cars, competitors are:For the Model 3:BMW i3Nissan LeafFor the Model X:Jaguar i-PaceAudi e-tronIn terms of size, the Model S did have any competition regarding sedans cars.Nevertheless, the 2020 Porsche Taycan might be the biggest Model S' rival.

Investment in R&D

Here is a very interesting article on Tesla's investment on R&D from 2010 to 2018In addition, when talking about R&D, we could link it to Session 13's new product development. Companies invest heavily on R&D because they want to decrease Time to Market, while taking into account Time to Perfection. Tesla has only three cars (very low compared to other car manufacturer) today in the market but has already announced two other vehicles that will enter production in the next two years. Therefore, it is crucial for Tesla to reduce Time to Market.

Technical issues

Technical issues at Tesla could be link to Session 16: "Building a Resilient Supply Chain". During this session we saw the framework: Redundancy, Flexibility and Culture. Redundacy is substantial for Tesla in terms of technical issues. It will help to react better from shocks described below for example. Tesla has had numerous problems with its vehicles.First, the autopilot sometimes didn't work accordingly to plan after Tesla realized a software updates resulting in crashes.Also, numerous cars caught fire after after their batteries started to catch fire.In total, 14 vehicles caught fire since 2013. Comparing to the rest of the industry, this number is quite high as Tesla has sold around 900,000 units since 2012 (Toyota sold 9.6 millions cars in 2019 alone).

/arc-anglerfish-arc2-prod-infobae.s3.amazonaws.com/public/3OFYUKL3ZJAJZF44SJW5QB42UE.jpg)