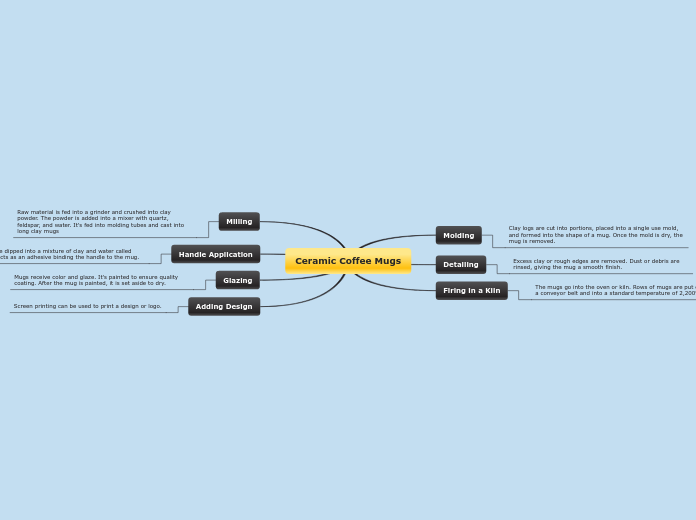

Ceramic Coffee Mugs

Molding

Clay logs are cut into portions, placed into a single use mold, and formed into the shape of a mug. Once the mold is dry, the mug is removed.

Detailing

Excess clay or rough edges are removed. Dust or debris are rinsed, giving the mug a smooth finish.

Firing in a Kiln

The mugs go into the oven or kiln. Rows of mugs are put onto a conveyor belt and into a standard temperature of 2,200º F.

Milling

Raw material is fed into a grinder and crushed into clay powder. The powder is added into a mixer with quartz, feldspar, and water. It's fed into molding tubes and cast into long clay mugs

Handle Application

Handles are dipped into a mixture of clay and water called Slip. This acts as an adhesive binding the handle to the mug.

Glazing

Mugs receive color and glaze. It's painted to ensure quality coating. After the mug is painted, it is set aside to dry.

Adding Design

Screen printing can be used to print a design or logo.