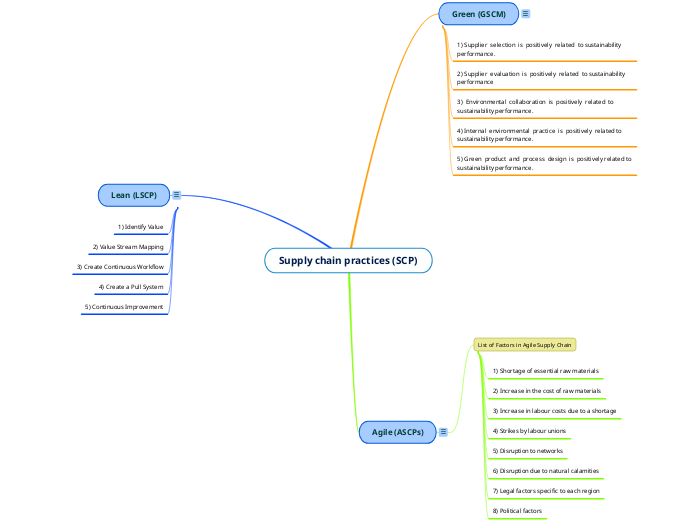

Supply chain practices (SCP)

Green (GSCM)

1) Supplier selection is positively related to sustainability performance.

2) Supplier evaluation is positively related to sustainability performance

3) Environmental collaboration is positively related to sustainability performance.

4) Internal environmental practice is positively related to sustainability performance.

5) Green product and process design is positively related to sustainability performance.

Agile (ASCPs)

List of Factors in Agile Supply Chain

1) Shortage of essential raw materials

2) Increase in the cost of raw materials

3) Increase in labour costs due to a shortage

4) Strikes by labour unions

5) Disruption to networks

6) Disruption due to natural calamities

7) Legal factors specific to each region

8) Political factors

Lean (LSCP)

1) Identify Value

2) Value Stream Mapping

3) Create Continuous Workflow

4) Create a Pull System

5) Continuous Improvement