Granulation

Dry

Two specialy grooved rolls,

which rotate toward each other

(moving in oppositedirection)

Chilsonator

Spray

Single punch tablet machines

This method employing moist granules

and dry them in one operation

Fluidized bed granulator

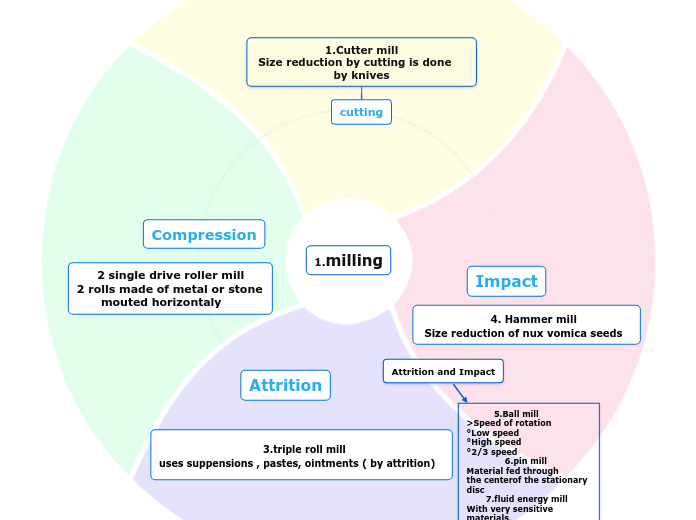

Attrition and Impact

5.Ball mill

>Speed of rotation

°Low speed

°High speed

°2/3 speed

6.pin mill

Material fed through

the centerof the stationary disc

7.fluid energy mill

With very sensitive materials,

inert gas may be used

8.colloid mill

Colloid mill not used for

size reductionofsolids

2.MIxing

Liquid

mixing

Air jets

These symptoms use pressurized air or gas

paddles mixers

impeller mixers

use for liquid of low viscosity

propeller mixers

propeller shift may be mouted at the angle

Semi

solid

mixing rolls

l. Roto feed mixer

The matenial is fed into

the end of the chomber

mix - Extuders

l. sigma arm mixer

can be single or double arm

kneaders

l.planetary mixer

contain tow can

Beaters

powder

mixing

Tumbling mixers

3.Vertical Impeller mixer

It's required little floorspace

2. High sheer mixer

The particles movement tends

to quickly mix the powder

1.Sigma blade mixer

The rotation of the sigma blades

couses the materialtomix

Agitation mixer

2 single drive roller mill

2 rolls made of metal or stone mouted horizontaly

4. Hammer mill

Size reduction of nux vomica seeds

3.triple roll mill

uses suppensions , pastes, ointments ( by attrition)

Compression

Attrition

Enter the name for this step.

You can add subtopics to each step selecting it and pressing Insert. Subtopics can provide more detail about the step.

Impact

You can rearrange the step topics as required to fit your diagram.

cutting

Enter the name for each step.

You can add subtopics to each step selecting it and pressing Insert. Subtopics can provide more detail about the step.

1.Cutter mill

Size reduction by cutting is done by knives

1.milling

Type the name of this cycle and press Enter.