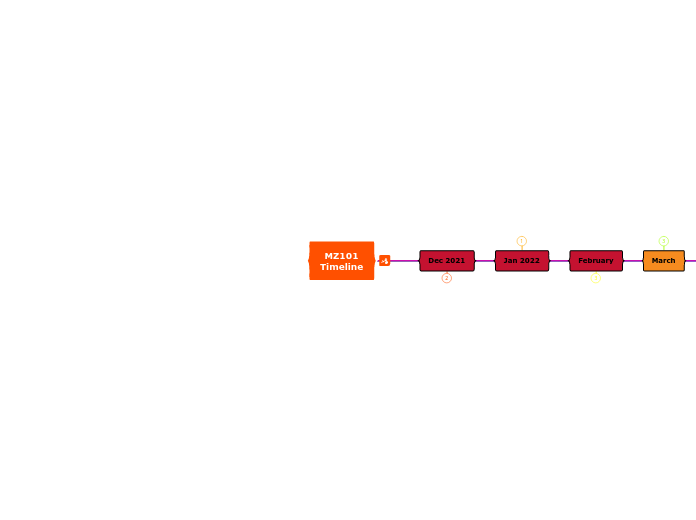

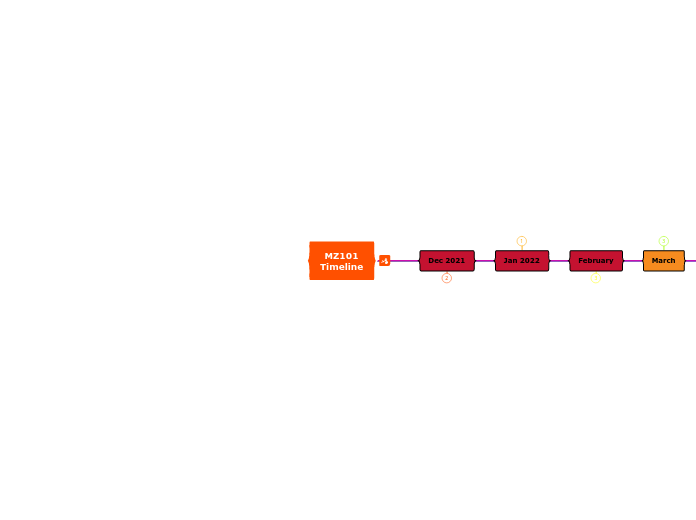

MZ101

Timeline

1st MZ101 production unit shipped

World of Concrete

Operations owns MZ101

manufacturing efforts

Jan 2023

CE certification plan complete

Final setup of manufacturing line

Handoff to operations to

execute on manufacturing

Final update and release of all

production drawings (Rev B)

December

Software validated

1st MZ101 pre-production unit assembled

and debugged

Assembly documentation for

manufacturing floor builds

Draft CE assessment complete

November

GUI complete

Pre-orders?

MZ101-P2A working unit?

Only necessary if there is a major learning from P1 build.

FEA and testing have shown no major issues, even at 30 degrees we still have almost a 5x factor of safety as a foreseeable misuse case.

Executable marketing plan

October

Show unit / marketing requirements?

Start system software validation

and debug for production

Draft risk assessment complete

Risk assessment complete

GUI requirements locked down

MZ101-P2A design release?

(Parts or machine)

Inhouse testing with real masons

Production software functions

locked down

Customer R&D design review

application meeting

Production design release for 1st

manufacturing test run (Rev A)

September

Working MZ101-P1B production

intent prototype

- As a result of the motor issue, further development was done on P1 in parallel to further de risk the need for a P2 build further.

GUI layout requirements

outlined

Customer facing spec sheet

Prepare customer design review

application presentation

Working MZ101-P1A production

intent prototype

Marketing pictures and videos???

Marcus on leave

Finalize complete software

validation plan

Validate production intent

motor controls w/ temperature

compensation complete

4/28:

- pending arrival of InMotion parts for testing on MZ2

August

MZ101 official production forecast

for vendors to protect supply chain

4/15

- Sales team requested a rough spec sheet and rough costing for pricing ROM to gauge volume market by.

4/28

- Had to push effort from April to May because fabrication parts not back from quote yet. Working to get rest of critical components in BOM updated in parallel.

Marketing strategy outline

Start ordering long lead electronics

to protect production supply

Executable manufacturing plan

for setup in new building

Work with vendors to get forecast

and lead time understood for long

lead electronics.

Setup electric gripper testing

on ML150 for application,

debug, and robustness

- testing completed and went well. Servos were programed to have self held safety limits independent of controller board.

- Johnathan is having issue with production intent board and cooked servo and/or board so had to take parts from working prototype for him to continue.

- Ordered more servos so we have spares, will also order a few metal gear servos as a backup in case we find plastic servos not to last.

Electrical documentation complete

with all critical components for

manufacturing MZ101

Perform second full FEA of production

intent design release

July

Validate critical functions

of wireless handle w/ gripper

Perform first full FEA of production

intent design release

Review FEA Results

June

Evaluate use cases of all current

ML150 accessories

Primary function testing

and debug

High level manufacturing strategy

outline for new building setup

Resolve motor & gearbox

supply chain issues

May

Benchmark MZ101 cost

- Waiting on quotes from vendors, drawings released mid April.

- Need quotes back so final design changes can be made to weldments for fabrication for prototype.

RT mobility application

study complete for JLG mobility

base requirements

Build MZ100-2 for testing critical

controls design changes

- Must push to till next month (May) because of vendors not providing parts. May come first week in May but working to verify since engineering is believed to be done on their end for production of parts to CR.

Release MZ101-P1 drawings for

fabrication

MZ101 application testing plan

MZ101 robustness testing plan

April

Dave L drastic hours cutback?

- Jake full time to resolve

- Minor handle tweaks

- Detailing still needs to be done

- Cover started but still needs a bit of design work

- Parts for 5 old handle weldments should be in soon

- No other tasks lingering for Dave L

Interior mobility application

study complete for JLG mobility

base requirements

Resolve battery and power

issues in cold weather

4/28

- Switching to inventus battery will simplify design and allow faster warm up with internal heating cells while charging / discharging.

MZ101 Production intent

prototype weldments

release for quoting

March

Resolve Fort Robotics issue

Resolve overturning moment

issues with MZ100

Design MZ101

February

Re-evaluate requirements and

design of MZ100

Resolve temperature

and motor feel issue

Perform initial application

study

Jan 2022

MZ100 design release

Dec 2021

Initial controls feel signoff

Handle wireless resolved