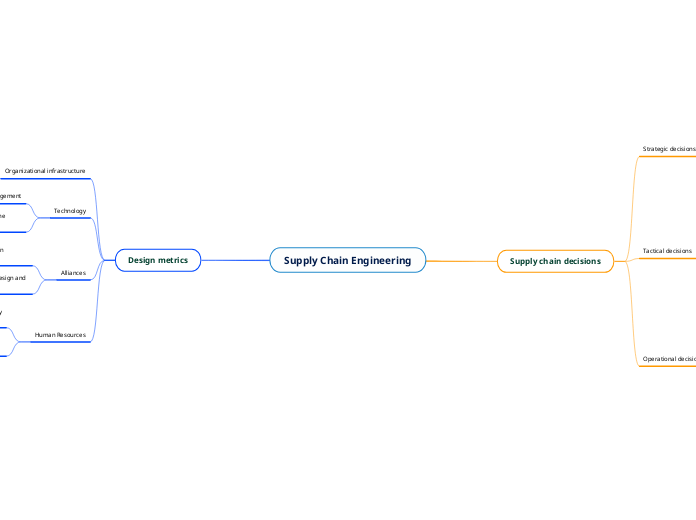

Supply Chain Engineering

Supply chain decisions

Strategic decisions

Supply chain network design (location of plants, distribution centers, warehouses, etc.)

Production and supply (in-house manufacturing or subcontracting, choice of suppliers and partners)

Information technology (supply chain coordination through internal software or commercial packages)

Tactical decisions

Purchases (quantity and time of purchase)

Production planning (quantity and time of production)

Inventory management (balancing between replenishment costs and shortage risks)

Transportation (choice of shipping modes and frequency)

Distribution (coordination of the replacement of distribution centers with production)

Operational decisions

Vendor delivery scheduling

Setting customer order due dates

Daily or weekly production schedule

Allocation of limited supplies between backorders and demand from new customers

Design metrics

Organizational infrastructure

Collaboration and coordination between companies in the supply chain

Technology

Information technology for supply chain management

Manufacturing technology that enables efficiencies in the supply chain

Alliances

Strategic collaboration with suppliers and supply chain partners

Assumption of responsibility by the suppliers in the design and manufacture of the product

Human Resources

Technical employees with skills in analysis and design of supply chain networks

Managerial employees with conceptual understanding of key issues