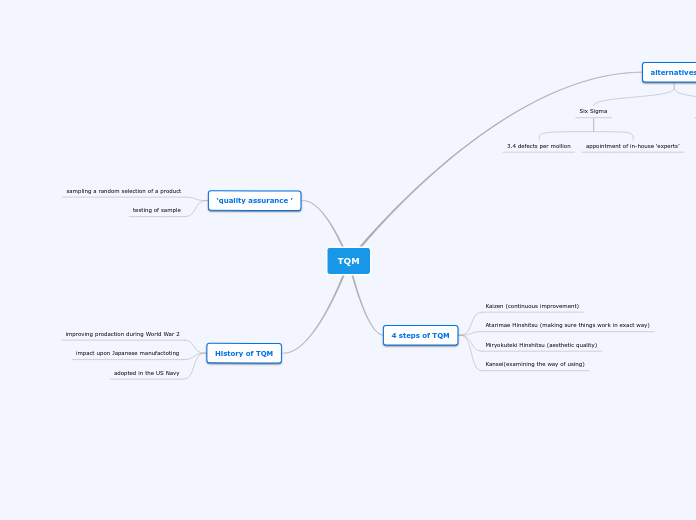

TQM

alternatives

Six Sigma

3.4 defects per mollion

appointment of in-house ‘experts’

lean manufactoring

Flexibility

Building a long-term relationship with suppliers

Continious improvement

Perfect first-time quality

Pull processing

4 steps of TQM

Kaizen (continuous improvement)

Atarimae Hinshitsu (making sure things work in exact way)

Miryokuteki Hinshitsu (aesthetic quality)

Kansei(examining the way of using)

‘quality assurance ’

sampling a random selection of a product

testing of sample

History of TQM

improving prodaction during World War 2

impact upon Japanese manufactoting

adopted in the US Navy