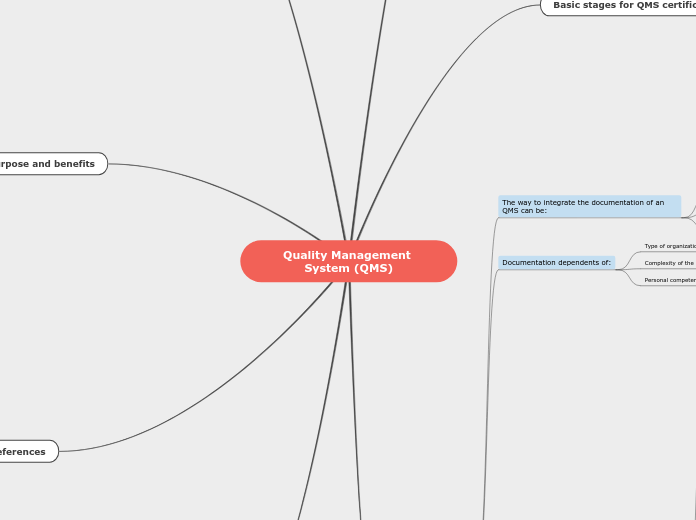

Quality Management System (QMS)

Quality management

Define as:

It comprises all activities that are required to plan for quality in an organization and the activities to satisty quality objectives.

It has four elements

Quality planning

Are the activities that are performed to establish quality objetivesn identify quality requirements, plan for a QMS and plan for process execution.

Quality control

Activities to fulfill requirements for quality. It focuses on the product.

Quality assurance

Is comprises all the planned and systematic activities implemented within the quality system that can be demostrated to provide confidence that a product or service will fulfill requirements quality.

Quality improvement

Enhancement in the effectiveness and efficiency of process and enhacement in the extent to which a product satisfies applicable requirements. It includes The Deming cycle (Plan, Do, Check and Act).

Basic stages for QMS certification

In includes:

Request

It´s a kind of contract where specifies size company, the company scope and the specific time to certificate.

Documentation review

The main document that a the organization review is the quality manual in order to know a general point of view of the company or organization.

Previous evaluation

It´s a first visit to the company installations with the objective to know how much well-prepared the company is. No all companies need a previous evaluation.

Evaluation

It is determined when quality system documentation agrees to norm requirements. Two or three auditors stay in installation for two or five days, but the audit time depends of comañy size.

Certification

There are three results:

Approval

It agrees with all the requirements.

Provisional approval

It agrees with almost all the requirements, they give you time to make need changes.

Disapproval

When it disagrees with the requirements, the quality system documentation is not present in the compañy.

Supervision

Certifications have a validity time. when this time is about to run out, auditors must go back to the compañy to verify if it still agrees with the requirements.

Documentation

The way to integrate the documentation of an QMS can be:

Own organization procedures itself.

Structure of the standard norm used.

A mix of them.

Documentation dependents of:

Type of organization and its activities.

Complexity of the processes.

Personal competence.

What kind of documentation can I find in the QMS?

Quality policies.

It tells the global intation of an organization made by high direction. it relates to an organization or company´s mission and vision.

Its principles are:

Customer focus.

Leadership.

Commitment to people.

Process focus.

Continuous improvement.

Decision making

Relation management.

Quality manual

It´s a document that specifies the QMS. The manual adjusts to the complexity of the organization.

The content of the quality manual is:

Organization for quality.

Quality function planning.

Project and design control

Relationship with providers.

Process control.

Final control.

Special process

Handling, storage and dispatch.

Service and assistance.

Non-conforming materials.

Quality cost.

QMS audits.

Note: no all the companies have the same content.

Document procedures

It´s the document tha show you the way of carrying out a set of systematized activities with start and end dates.

Work instructions

Those are detailed description of how to perform and document a task. It describes the

material, equipment and documentation used

A work instruction can be:

Written detailed description.

Flowcharts.

Templates and Notes.

Drawings.

Videos.

Check lists.

Forms and records

Used to write down the results.

Quality plans

Specification of the procedures and associated resources to apply. It relates to strategic planning.

Specification

It´s the document stipulating requirements.

Can be relate to:

Activities

Like: procedure, process and test specification.

Products

Like: product specification and performance.

External documents

Those documents that contain information related to products and services contracted externally. It also includes new laws and norms established by the nation.

Definition

It is a kind of management system to lead and control an organization regarding quality.

Purpose and benefits

To show the QMS´s structure.

Groups information and their functions.

To show the compromise of the high direction with quality.

To help employees to know what de need to do inside of an organization

To ease the understanding between employees and direction.

To keep a base of expectations work.

To declare activities.

To generate records of achieving goals.

Database of employees information.

To maintain order and balance.

Operation coherence.

To work in a continuous improvement process.

To provide customer confidence.

Suppliers requirements.

To establish a way to audit the QMS.

References

ISO 9000:2005

ISO 10013

Vivek Nanda (2005). Quality management system handbook for product development companies. A CRC press book.

Peach, Robert W. (1999). Manual de ISO 9000. Distrito Federal, México. Editorial: McGraw-Hill Interamericana editores.

Pola Maseda, Ángel (1988). Gestión de la calidad. Barcelona, España. Editorial: Marcombo Boixareu Editores.

Información

Where can I store the information

Paper

Electronic media

Advantages:

Available at all times.

Changes and accesses are faster and controlled.

We can print any document whatever we want.

We can access to a document wherever we want.

Deleting a document is easier.

Reduces pollutants.