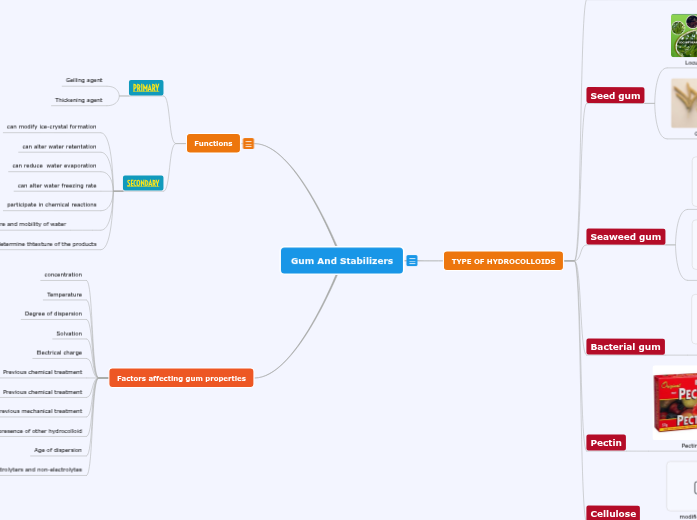

Gum And Stabilizers

What is Gum?-Is a polysaccharides chains contain hydroxyl group which can bind to water.- Also have side chains such as ester, sulfates and acetyl. - Some gums are react strongly in presence of other ingredients. Example : sodium alginate does react actively with calcium.

TYPE OF HYDROCOLLOIDS

Plant exudates

Gum arabic

GUM ARABIC - from Acacia senegal L STRUCTURE:- D-galactose, L-arabinose, L- rhamnose, D- glucurunic acid - Molecular weight : 250,000 to 1,000,000- Very complex structureADVANTAGES:- High water solubility- Flavor encapsulationsAPPLICATION:- Emulsification (w/o or o/w) in salad dressing- Flavor fixation in powder drinks milk- Crystallization control in ice-cream

aSeed gum

Locus Bean Gum

LOCUS BEAN GUM (SOURCE : CAROB TREE (ceretonia siliqua)STRUCTURE:- A galactomannan ( man : gal = 4:1)- Molecular weight = 300,000 to 360,000*contain long stretches of bare mannose backbone which responsible for synergismSOLUBILITY:-Partially soluble in cold water but only under strong agitations. Totally soluble in hot water.SYNERGIES:- Good synergism with xanthan gum for every elastic chewy gum. Can built up quite strong gels. Useful in mayonnaise which required strong gels.APPLICATION:- Used in ice-cream, cheese productions and meat productADVANTAGE:- Have strong interaction with K-caraggenan -Good flavor release

Guar gum

GUAR GUM(SOURCE: cyamopsis tetragonolobus)- hydrates rapidly in cold water to give highly viscous dispersion.-Totally soluble in cold and hot water, and gives slimy solutions.-Good synergism with xanthan gum for extra high viscosity solutions. STRUCTURE:- Galactomannans which containing mannose and galactose monomers (ratio= 2:1)- Molecular weight : 1,000,000 to 2,000,000 daltons.Uses:-Processed cheese-Ice-cream-Baked goods-Meat- Dressing and sauce-Beverages

aSeaweed gum

CARRAGEENAN (SOURCE: chondrus crispus)3 TYPES:- kappa-carrageenan-lambda-carrageenan-iota-carrageenanSTRUCTURE:- A complex mixture of sulphated polysaccharides.CARRAGEENAN GELATION PROPERTIES:1) strongest gel - Kappa : with K+ ion-Iota : with Ca+ ion-Lambda: No gel2) Gel Texture -Kappa : Brittle-Iota : Elastic-Lambda: No gel3) Regeal after shear-Kappa : No-Iota : Yes-Lambda : No4) Syneresis-Kappa : Yes-Iota : No- Lambda: No5) Freeze-thaw stability-Kappa : No-Iota : Yes-Lambda : Yes6)Synergy locus bean gum (LBG)-Kappa : Yes-Iota : No-Lambda : No*Kappa, Iota and Lambda are all differentCARRAGEENAN PROPERTIES: In water- thickens (pseudoplastics) and gels-In milk- Thickens, gel, and reacts with milk proteins to stabilize the colloidial system-Kappa forms a thermally reversible gel in the prsence of K+ ions- gels are normally brittle and prone to synersis. Can be remedied by addition of small amount of LBG..USES:1) Puddings- eggless custard2) Chocolate milk-particles suspensions3) Cheese products-Prevent whey seperations4) Ice-cream- Crystallizations control5) Meat-Protective coating to prevent oxidative rincidity6) Salad dressing -Stabilizers

Alginates

ALGINATE ( Source = brown seaweed, Macrocystis pyrifera)STRUCTURE:- D- mannuric acid, L- guluronic acid-Poly M blocks-Poly G blocks-Alternating M-G blocksPROPERTIES:-Low molecular weight fractions-Non-newtonian behavior increase with: -Increasing degree of polymerizations (DP) - Increasing concentrations - Presence of Ca+ instead of Na+-As temperature increase, viscosity decrease-Good stability in the pH range 5-10 -maximum viscosity occur between pH 6-8 -Degradation occurs at low pH 1-4-Alginate is fairy resistant to microorganismALGINATE GELATION:-Ca+ gels-Acid gels-Combination gels*can form heat stable gel*Sodium alginate react strong with calcium produce alginate thick when mixed in water, but if calcium was added it will form a cold water gel.USES:1) Ice-cream2) Bakery icing3) Bakery jelly4) Meringues5) Salad dressing6) Pimento stuffe olives7) Frozen reformed onion rings

Bacterial gum

Xanthan gum

XANTHAN GUM -polysaccharides produced from fermentation of CHO substrate with Xanthomonas CampestrisSTRUCTURE:-Basically a derivative celluloseXANTHAN PROPERTIES:-Xanthan is soluble in hot or cold water to produce dispersion of high viscosity at low concentration-The dispersion are highly pseudo-plastic (shear-thickening)USES:1)Beverages-good flavor release ( due to shear-thickening)-Cloud stabilizers2) Frozen food-Pie filling-Increase freeze-thaw stability3) Relishes-Good acids stability 4) Xanthan -LBG gels and puddings-Instant gels and pudding

Pectin

Pectin

PECTIN derived from peel of citrus fruitsSTRUCTURE:-Chain of polygalacturonic acid units Molecular weight up to 150,000TYPES:-HMP (High methoxyl pectin)- DE>50%:To form gels, soluble solid content : 55-58%, pH 2.8-3.8:Used in jams:Not heat reversible: Gels at high solids and low pH-LMP(Low methoxyl pectin)-DE<50%:DE < 50 %:LM are heat reversible:-Conventional low methoxyl pectin (LMP) -Amidiate low methoxyl pectin (ALMP): The presence of Ca2+ needed to form gels with low solid content and wide pH range 1-7 :ALMP is very reactive than Conventional low methoxyl pectinUSES:-Jams-Jellies

Cellulose

modified cellulose

CELLULOSE: -Derived using alkaline treatment which convert cellulose into an ether (e.g: CMC - sodium carboxythylcellulose and HPMC-Hydroxypropylmethylcellulose.CMC::Monovalent salts, soluble:Divalent salt, hazy:Trivalent salts, gel or precipitate:React with proteins to increase viscosity of dispersionsCMC PROPERTIES:Water soluble:Pseudoplastic dispersions:Stable at pH 5-10, best pH 7-9CMC USAGE: Pie filling-to prevent synersis: Breads- Has an anti-staling effect: Dietatic food- to provide bulk and body replacer that normally given by sucrose*MC and HPMC formed gel when heated and return to it original liquid viscosity when cooled.

Functions

Functions & Applications1- Adhesive - Bakery glaze2- Crystallization - Ice- cream3- Cloud Agent - Fruit juice4- Emulsifier - Salad Dressing5- Film former - Sausage casing6- Foam stabilizers - Beer, Whipped topping7- Geling agent -Puddings8-Suspending agent - Chocolate milk9-Syneresis in inhibitor - Cheese, frozen foods10- Thickening agent- sauces and gravies

PRIMARY

Gelling agent

Thickening agent

SECONDARY

can modify ice-crystal formation

can alter water retentation

can reduce water evaporation

can alter water freezing rate

participate in chemical reactions

can controlled the structure and mobility of water

can control or determine thtexture of the products

Factors affecting gum properties

concentration

Temperature

Degree of dispersion

Solvation

Electrical charge

Previous chemical treatment

Previous chemical treatment

Previous mechanical treatment

The presence of other hydrocolloid

Age of dispersion

Presence of electrolyters and non-electrolytes