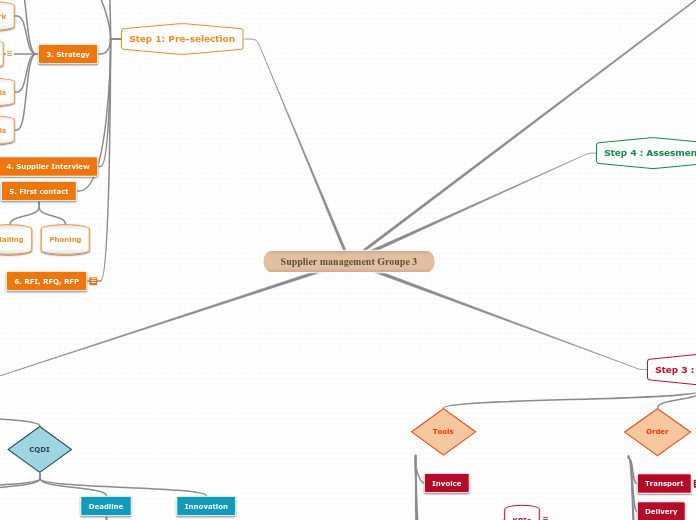

Supplier management Groupe 3

Step 5 : Partnership

Cooperation

Co-conception

Co-development

Joint actions

Communication

Relation

Longterm relation

Association

Loyalty

Framework contract

Step 4 : Assesment

Tools

PARETO

Dashboard

Ishikawa diagram

Indicators

KPIs

OTDs

OTQs

PPM

Means

Currative actions

Corrective actions

Financial Analysis

Results

Continuous improvement

Partnership

Results

Step 3 : Follow up

Tools

Invoice

Indicators

KPIs

OTDs

OTQs

Reject

Number of issues / year

Service scorecard

Assesment grid

Reporting

Dashboard

Order

Transport

Delivery

Issues

Forecast

Actions

Penalty

Corrective actions

Treatment purchase request

COPIL

Stock

Stock rotation

Advance of stocks

Critical stock coverage

Step 1: Pre-selection

1. Market research

PESTEL

PORTER

SWOT

2. Sourcing

Location

Certifications

Réputation

Core business

Experience

Client reference

Subcontracting

3. Strategy

Purchasing Strategy

Benchmark

Specifications

Financial Analysis

Risk Analysis

4. Supplier Interview

5. First contact

Mailing

Phoning

6. RFI, RFQ, RFP

Step 2 : Selection

Tools

Scoring grid

Supplier SWOT

Total cost of ownership

Selection process

Consultation

Bid analysis

Bid presentation

Negociation

Selection

Contracting

CQDI

Cost

Quality

Services

No Quality

Goods

PPM

Deadline

Schedules

OTD

Innovation