door victoria townsend 15 jaren geleden

368

Capstone Discussion Fri Jan 14

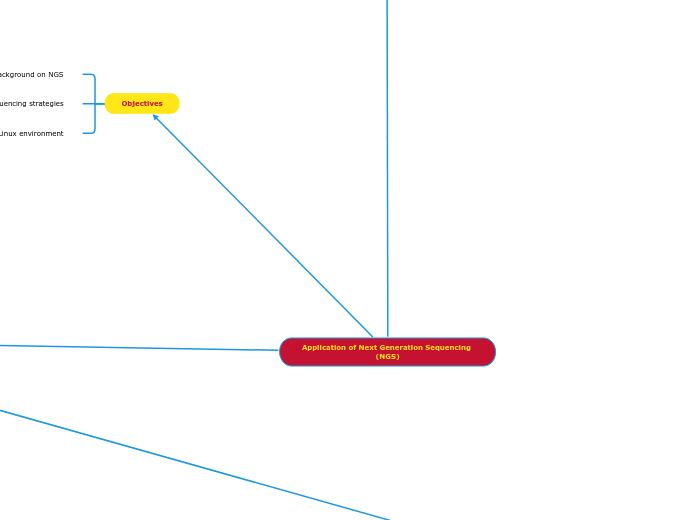

The following mindmap is from the group discussion in the industrial engineering capstone class on the morning of Friday January 14. The topic of discussion was on "engineering specifications" -- what are they? What are some examples? How do we define them? Etc.