Economic Resources Activity

By: Sanjayan Sivapatham and Soham Chakrabarty

Natural Resources

It starts with the mining of resources. Materials are extracted from all over the world.

Lithium Cobalt oxide and carbon graphite are materials used for batteries in phones.

Gold and Copper are used for the wiring of the phone.

Platinum and tungsten are also used for the circuitry of a phone.

Aluminum oxide and silicon dioxide with an ultra-thin layer of indium tin oxide is used for the screen.

Plastic is also used as it makes the phone more resistant to damage. The back of newer models of an Iphone, usualy have glass on the back which is usually prone to break if the phone falls.

Other Resources that can commonly be found in phones are:

Graphite

Aluminum

Nickel

Magnesium

Silver

Tin

Lead

Silica

Capital Resources

Factories are required to mass manufacture smart phones.

Land is required in order to built factories.

Money is required to purchase the resources for the smart phone and to pay for employees.

Machines are used to mass produce smart phones.

/cdn.vox-cdn.com/uploads/chorus_image/image/48700379/NASA-Super-Guppy-Orion-Transport.0.0.jpg)

Airplanes or trucks are used to ship the smart phones to retail shops or distributors.

Packaging and Casings are used to display the phone.

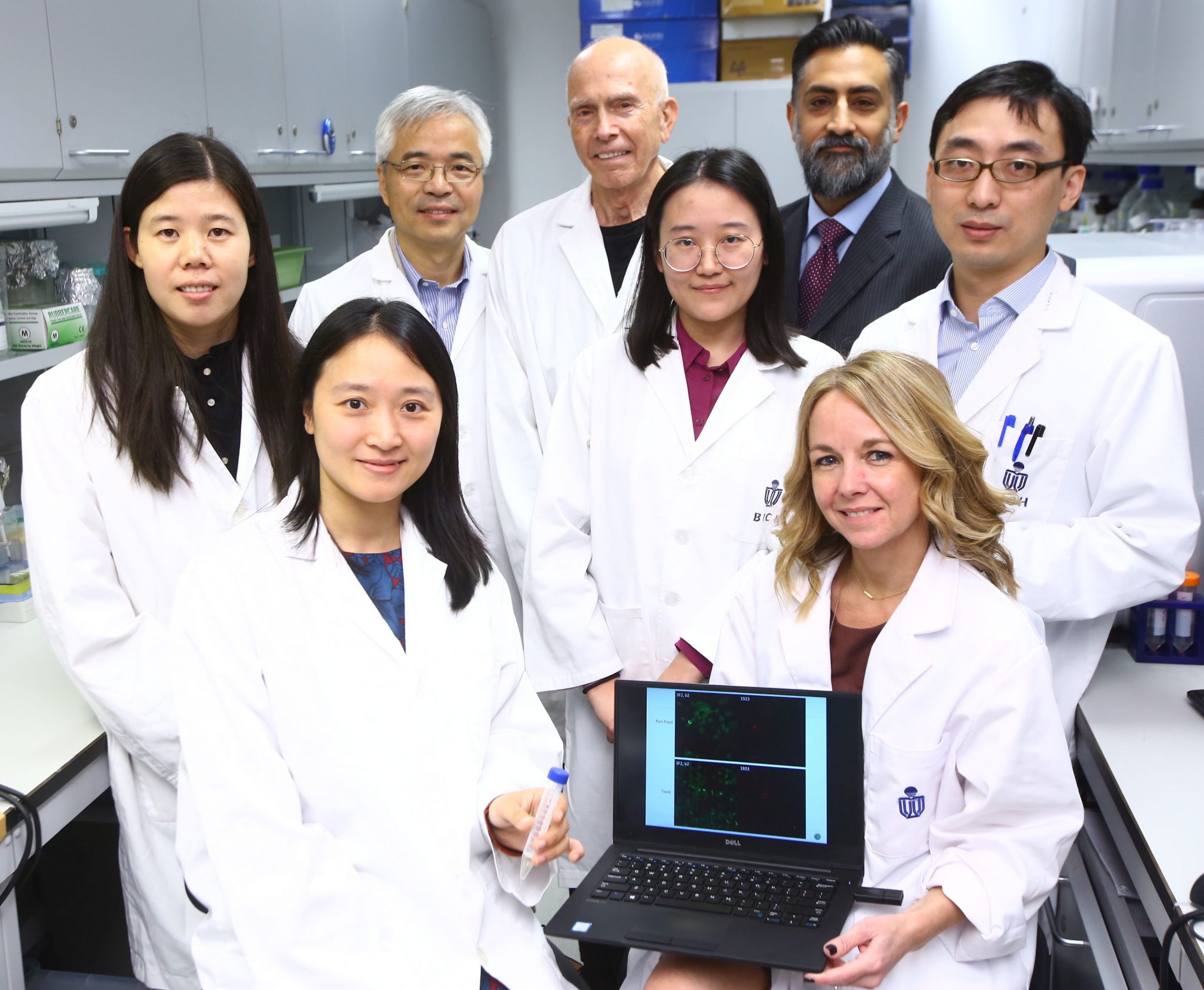

Human Resources

A lot of people are involved with the manufacturing such as design team, electronics engineering team, and software team.

A research team designs the prototype of the smartphone in which the aesthetics must be considered in the design. After the research team has a consensus design the electronic engineering team takes over.

The electronic engineering team must make decisions such as size of display screen, type of battery, and type of components used in the smartphone. After the electronic engineering team is satisfied with the work they ask the higher officials for approval.

If the higher officials approve the design, the software team takes over the design. The software team must make many important decisions such as installing the operating system to the smartphone, compatibility of the hardware to the operating system and if the phone is operating properly. If the design, hardware and software is working properly the design of the smartphone will be sent to the testing phase.

Before production, a testing team tests the smartphone in many aspects such as quality and performance. Some tests may include bend tests and water tests. If the final prototype passes all tests and works fine, it will be ready for mass production.

The mass production usually takes place either at the smartphone's own plant or from other manufacturers known as original equipment manufacturers (OEM).After mass production, the packaging of the smartphone follows.

The smartphone company must decide what accessories to include and packaging to use for the smartphone. The final step is shipment.

The final step is shipment. The smartphones are shipped to places such as distributors and retailers across the world. As you can see, many people are involved in the process of making a phone.