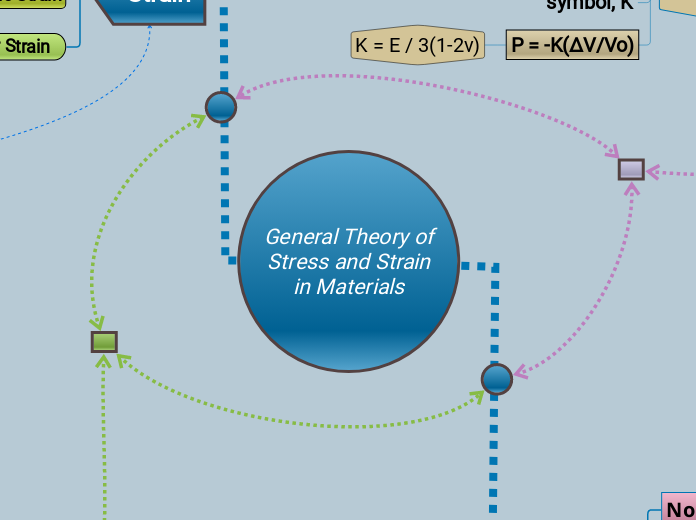

General Theory of

Stress and Strain

in Materials

Stress

Normal Stress

Compressive Stress

τ = F / Ao

F = compressive force

Ao = original area (before loading)

Tensile Stress

σ = Ft / Ao

Fs = tensile force

Ao = original area (before loading)

Shear Stress

τ = Fs / Ao

Fs = shear force

Ao = original area (before loading)

unit, Pa or psi

unit, unitless

Strain

Lateral Strain

εL = -δL / wo

Longitudinal Strain

ε = δ / Lo

Volumetric Strain

(ΔV/Vo)undefined

Shear Strain

sideways force exerted on a medium

Stress-Strain Curve

Elastic State

Proportional Limit

σ = E ε

Yonge's Modulus

or

Modulus of Elasticity

symbol, E

unit, gPa

rise/run

E = Stress/Strain

measures how aeasily a material streches or deforms

Elastic Yield Point

Yield Strength

unit, Pa, psi

Plastic State

Lower Yield Point

Ultimate Yield Point

Ultimate Yield Strength

unit, Pa, psi

Ultimate Stress

unit, Pa, psi

Fracture Point

Breaking Stress

unit, Pa, psi

Reversible Deformation

Permanent Deformation

Poisson's Ratio

ν = εL / ε

Lateral Strain / Longitudinal Strain

Mechanical Properties

Ductilty

%EL = [(Lf – Lo) / Lo] x 100

%RA = [(Ao – Af) / Ao] x 100

ability of a material to sustain a large permanent deformation

Toughness

the strength with which the material opposes rupture

Resilience

the ability of a material to absorb energy when it is deformed elastically, and release that energy upon unloading.

Elastic Shear Modulus

symbol, G

τ = Gγ

Shear stress/shear strain

G = E / 2(1+v)

measure of the ability of a material to resist transverse deformations

Elastic Bulk Modulus

measure of the ability of a substance to withstand changes in volume when under compression on all sides

symbol, K

P = -K(ΔV/Vo)

K = E / 3(1-2v)