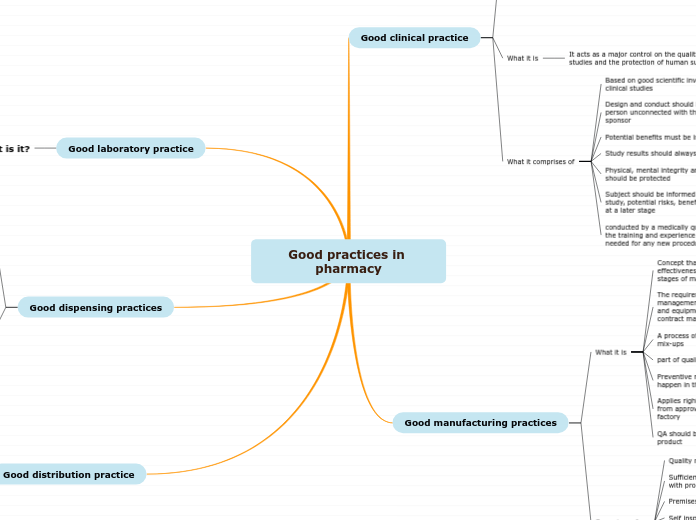

Good practices in pharmacy

Good clinical practice

For clinical trials

Clinical trials in Singapore

All clinical trials on medicinal products conducted in Singapore requires a clinical Trail Certificate

Additional info

The HSA through its Health Products Regulation Group, provides advice on the licensing of clinical drug trials

New applications for clinical trials certificates

Amendments to clinical trials protocols and informed consent documents

Serious adverse event report

Requests for CTC extensions

Because of

Increase in clinical research activities in Singapore

A need to grant appropriate protection to ensure the safety and well-being of trial subjects

Purpose

Set ethical and scientific standards for the conduct of clinical trials

Serves as an assurance that results obtained from clinical trials are credible

IRB

A committe that ensures health and safety of patients

What it is

It acts as a major control on the quality of clinical studies and the protection of human subjects

What it comprises of

Based on good scientific investigation including pre-clinical studies

Drug should be tested rigorously in labs in cell cultures and animals and healthy volunteer first

Design and conduct should be scrutinized by a person unconnected with the investigator and sponsor

Potential benefits must be in proportion with risks

Study results should always be reported accurately

Physical, mental integrity and privacy of the subject should be protected

Subject should be informed of the details of the study, potential risks, benefits and rights to withdraw at a later stage

conducted by a medically qualified person who have the training and experience in clinical trials and skill needed for any new procedure being investigated

Good manufacturing practices

What it is

Concept that covers the assurance of the safety and effectiveness of pharmaceuticals during all the stages of manufacturing

The requirements to cover such topics as quality management, personnel, documentation, premises and equipment, materials handling, validation, contract manufacturing, and self inspection

A process of preventing cross-contamination and mix-ups

part of quality assurance

Preventive measures tat is designed to ensure things happen in the correct manner

Applies rights from purchase of starting materials from approved suppliers until finished products leave factory

QA should be appropriate to the intended use of product

Comprises of

Quality management/ Quality System

Sufficient no. of qualified, experienced personnel, with proper training and hygiene

Premises and equipment

Self inspection audit

Documentation of specifications for raw materials/ packaging materials/finished products

Product process- proper handling of materials throughout process

Product complaints

Good laboratory practice

what is it?

Adequate facilities

Apparatus/ reagents must have validation, maintenance and proper storage

main area of activity must be covered by SOP

Physiological and biologicla testing system

Qualified Personnel with training

Proper receipt, handling, sampling and storage of all test and reference materials

proper storage and retention of records that allows for traceability

Good dispensing practices

What it is

Ensure quality of dispensed or compounded product by covering areas such s cleanliness, appearance, documentation, equipment, manipulative techniques, ingredients, calculations, counting etc

What it comprises

Cleanliness of drug, premises/bench/equipment/store

Documenting procedures and result

storage

Appearance: lab coat, hair, professional

equipment for extemporaneous preperations

counting devices must be kept clean daily and electronic counting equipment must be maintained for accuracy for accuracy

Good distribution practice

What it is

A concept that covers the assurance of the safety and efficacy of pharmaceuticals from the time they leave the factory gates to the point at which they are used by the patients

What is comprises of

Authorized/quality products

safe and secure storage conditions in warehouse as well as during transport

Avoid cross contamination

Right Product, Right Place, Right Time

FIFO system in stock movement

Full traceability in the distribution chain

Effective recall system