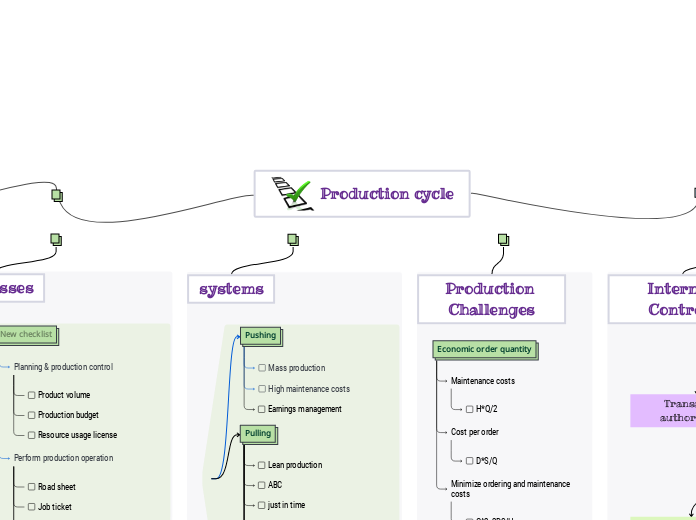

Production cycle

connections

Cycle

Market system

Cost system

Revenue system

general ledger

FRS $ MRS

processes

Planning & production control

Product volume

Production budget

Resource usage license

Perform production operation

Road sheet

Job ticket

moving ticket

storekeeping or buy material

Inventory controls

Check out the goods at the warehouse

Documents for registering documents in the property control unit

Cost accounting

Number of goods transferred

Rial amounts

Wage information

Machinery operation information

Function of workers

systems

Pushing

Mass production

High maintenance costs

Earnings management

Pulling

Lean production

ABC

just in time

TQM

Good relationships with trusted suppliers

Flexible production

Staff with a team attitude

Ability to use smart equipment

Production Challenges

Economic order quantity

Maintenance costs

H*Q/2

Cost per order

D*S/Q

Minimize ordering and maintenance costs

Q^2=2DS/H

Reorder point

Delivery time by the supplier

Consumption while waiting for initial inventory

1*2+percentage error

Internal Controls

Transaction authorization

Work orders

move tickets

materials requisitions

Segregation of duties

Inventory control separate from RM and FG inventory custody

Cost accounting separate from work centers

GL separate from other accounting functions

Supervision

Supervisors oversee usage of raw materials and timekeeping

Access

Limit physical access to finished goods, raw materials stocks, and production processes

Use formal procedures and documents to release materials into production

Accounting records

Work orders

cost sheets

move tickets

job tickets

materials requisitions

WIP records

FG inventory file

Independent verification

Cost accounting function reconciles all cost of productio

General ledger reconciles overall system