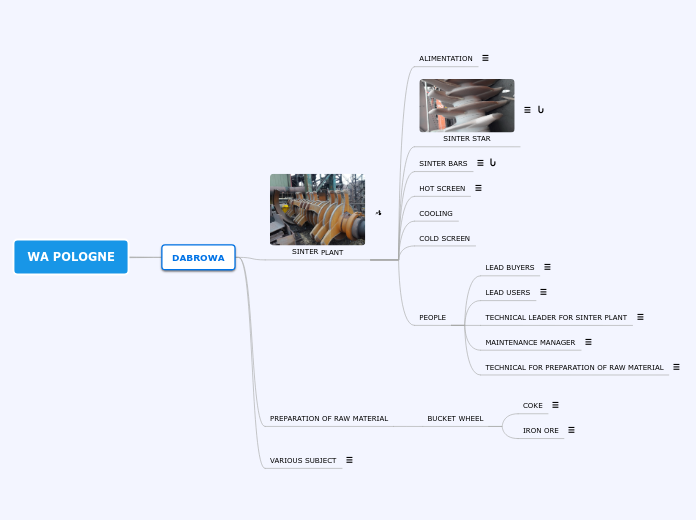

WA POLOGNE

DABROWA

ALIMENTATION

One year life time. We have to ask the base material and the drawing. With the both information we can propose a quote.

SINTER STAR

The life time of the 3 teeth model is 10 months to 1 year and 2 months. This is PIOMA company which manufactures the casting and subcontracts the hardfacing. It seems to be a HARDAFCE CNV-O type of product.The surfacic hardfacing is not resistant enough to have one year life time without reparation. Each 3 months maintenance service is checking the set and refurbish if necessary. We don't know which kind of reparation they made (surface hardfacing).There is another supplier delivering sets of sinter stars.The life time of the 4 teeth model seems to be 2 years. But this model presents some problems for maintenance because of the lack of place between teeth and bars. The thickness seems to be higher.The production rate is 600t/h. The production is quiet the same for the 3 lines. There is 30% recirculation. DABROWA unit is providing sinter for DABROWA and KRAKOW. The global production is 3.5Mt per line of sinter.Line 2 is equipped with 3-teeth stars and Line 3 with 4-teeth stars

dSINTER BARS

No information for the moment

dHOT SCREEN

Casted screens using refractory stainless steels. Lifetime depends on who supplied the screens.They change the complete screen even if only a part of it is damaged.TVV: 9 monthsPolish manufacturer: 3 monthsDrawings available from DRIVEEven if certain part of the screen is not worn , they change the entire set.

COOLING

COLD SCREEN

PEOPLE

LEAD BUYERS

Lukasz Cygan 795580951

LEAD USERS

Marcin Roziecki -668860141 (a quitté AM DABROWA en juillet 2018, remplacé par Sesha Prasad

TECHNICAL LEADER FOR SINTER PLANT

MICHAL BIALEK 664139218

MAINTENANCE MANAGER

PIOTR AUGUSTAK = Planning Specialist

TECHNICAL FOR PREPARATION OF RAW MATERIAL

ROMUALD URBANCZYK 795462276

PREPARATION OF RAW MATERIAL

BUCKET WHEEL

COKE

Michal have to get a bucket and make a drawing. Send it to us to make a quote for and piece in HARDPLATE.

IRON ORE

They would like to have a solution to have 3 years life time. The production is 3Mt par year.The problem is about sticking and not wear. For the moment they fix POLYURETHANE 15 to 20mm thickness. The problem we have seen is about product go beneath the protection. We could propose a complete protection with DURPLAST S.They gonna send us drawings for buckets and the center piece. We could make a trial or a complete set.

VARIOUS SUBJECT

It seems that they are not using standard plates (TUS) like in France. Neither HARDPLATE nor CERAMIQUE (600x300). KALENBORN is not present in DABROWA.The best solution could be to allow WAP to produce themselves their own TUS.