av Eryl Estavillo för 3 månader sedan

239

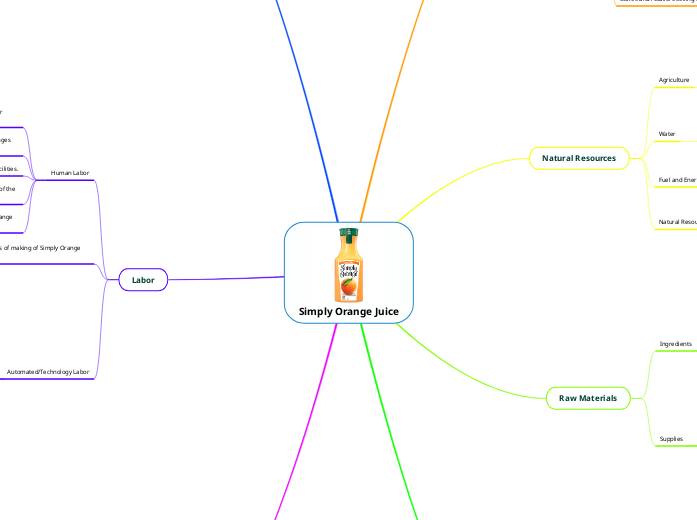

Simply Orange Juice

The production of Simply Orange Juice involves several meticulous steps, starting with the cultivation of oranges in select regions of the USA, Brazil, and Mexico. Once the oranges are ripe, they are harvested by farmers and transported to the production facility in Apopka, Florida.