L'Oréal Industry 4.0 - The Supply Chain as a business driver

Operations & Supply Chain Management For Professor Felipe AMADO QUINTANA NAVARROBy Lucrezia d’Arche - MiM Sept 2019 - S2

About L'Oréal

Key facts

L’Oréal has devoted itself to beauty for over 100 years. With its 34 outstanding brands in across 140 countries and 5 continents, the Group generated 26.9 billion euros in 2019 and counts more than 89k employees worldwide. Due to the nature of its business, L’Oréal operations and supply chain is highly complex. The company works with 70,00 suppliers, owns 41 manufacturing plants, 7 billion products that it delivers through 8 distribution channels and 500,000 delivery points. In 2017, the Group won the Operational Excellence Award recognizing the tremendous efforts it makes to ensure top quality operations.

Why L'Oréal

Beyond being a loyal customer to several of L’Oréal’s brands for cremes, perfumes, nail polish and much more (Khiel’s, Yves Saint Laurent, Biotherm, essie…), I had the opportunity to discover the Group under a business perspective. Indeed, when I was pursuing my Bachelor at McGill University in Montreal, Canada, I participated in a team of three to the L’Oréal Brandstorm annual international branding competition. The year we competed, we had three months to create a complete consumer experience to enable L’Oréal Men Expert recruit millennials through a new product and breakthrough service leveraging digital solutions and connected technologies. We worked closely with L’Oréal’s R&D department and were able to 3D print our prototype. We came up with an entire journey map and also had the opportunity to work with McCann, L’Oréal Canada’s advertisement agency. We made it to the top 10 teams in Canada. This competition tied me even more to the brand as it made me understand all the underlying drivers in terms of product development, operations, marketing that enable the Group to have so many loyal and happy customers.

My packaging prototype for the L'Oréal Brandstorm competition

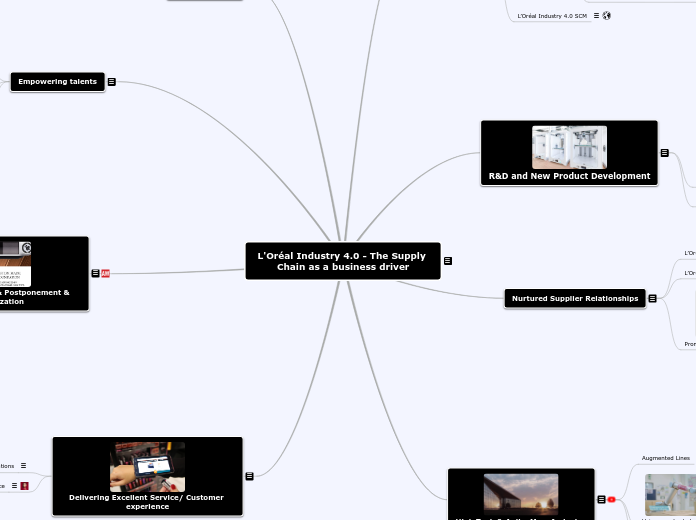

L’Oréal Industry 4.0 SCM

Customers want everything, anywhere, all the time. In response to this growing trend and to continuously be able to create value for customers & employees by delivering products faster without compromising quality, L’Oreal has adapted its supply chain based on Industry 4.0. L’Oréal is a global leader in embracing operational innovation and digitalization through its product development, manufacturing, and production lines. Here is a quick overview of L’Oréal’s Industry 4.0 before we explore it more in-depth.

a

R&D and New Product Development

A focus on R&D and New Product Development to accelerate the design and reduce the time-to-market & boost innovation...

Prototyping with 3D printing & VR

Fast 3D Prototyping & Virtual Reality enable L'Oréal to rapidly model future products by internalizing the manufacturing process of prototypes and indispensable production tools. It is a great way to reduce transport (motion and transportation waste), defects (information is corrected on the prototype). Previously considered one of the longest phases, today rapid prototyping only takes 24 hours. 100% of prototyping now involves prototyping. 14,000 prototypes were made in 2018 alone !“Instead of building models and testing products in the real world, we can develop 3D models in a matter of hours and use virtual simulation tools”, explains Stéphane Lannuzel, Operations Chief Digital Officer .The picture shows our 3D prototype done with L'Oréal during the competition. It's amazing to materialise an idea !

"Make Your Own Technology"

Last June, L’Oréal launched its 4.0 Technology Incubator created especially for its employees and dedicated to the industry and supply chain of the future. The MYT helps to identify, develop and implement ideas thanks to the new 4.0 technologies and agile methods (ideation - incubation - acceleration). In this way, they have a Kaisen approach, one in which employees work together to proactively “change for the better” by continuously improving current processes & products. Indeed, internal L’Oréal teams can create, prototype and transform their ideas into concrete achievements and support international deployment.

Nurtured Supplier Relationships

L'Oréal nurture its relationship with its suppliers to ensure long-term commitment and win-win situations undertakes concrete actions...

L’Oreal Campus for Suppliers

L’Oréal has been applying Kanban methodology, one that consists in regulating the flow of goods both within the factory and with outside suppliers and customers. They rely on automatic replenishment through signal cards that indicate them when more goods are needed. This enables L’Oréal to eliminate waste from inventory and overproduction. L'Oréal Campus for Suppliers is a digital platform where L’Oréal and its suppliers share the Group‘s stakes and invent together the beauty of tomorrow.

aL’Oréal Buy & Care Program

The "L'Oréal Buy & Care Program" is a way to select suppliers that meet L’Oréal’s social, environmental and ethical criteria and ensure alignment throughout the supply chain & operations. L’Oréal performs regular evaluation of its suppliers to make sure they meet defined standards & to establish long-term, transparent relationships with high-quality suppliers.

a

Promoting collaborative innovation

L’Oréal aims at building a two way and mutually beneficial relationships with strategic supply partners to deliver greater levels of collaboration, innovation and competitive advantage and to deliver even more value than could be achieved through a traditional, transactional purchasing arrangement.For example, since 2017 L’Oréal pursue Open Innovation with its partners & suppliers. It gives both L’Oréal and its suppliers to combine expertise, databases and research to continuously improve and develop new technologies to stay ahead of the game.

a

High Tech & Agile Manufacturing

High Tech & Agile Manufacturing as a response to the fast-beauty trends while keeping up with high quality standard. L’Oréal focuses on operator autonomy, which includes augmented lines, collaborative robots, connected devices that still ensure flexible operations. The L’Oréal Lassigny factory has just celebrated its 50th anniversary and is one of L’Oréal’s renowned factories. Check out the attached video for a quick overview of how operations work there.

Augmented Lines

Fully has automated warehouse with high speed automated processes - L’Oréal applies the concept of Jidoka by having equipment that partially automates the manufacturing process and to automatically stop when defects are detected. In this way, workers can frequently monitor multiple stations (which also reduce labor costs) and many quality issues can be detected immediately (which helps improving quality).Automatic Guided Vehicles (AGVs) – Dematic AGVs are fully mobile robots that can move and transport items within production, warehouse and distribution environments. AGVs provide reliable, autonomous mobile robotic solutions for where space is at a premium, flexibility is critical and operational efficiency is an imperative. Vehicles supply all of the packaging materials to their production line and transport finished products from production to the wrapping line.

Using smart robots: “Cobots”

The factories use smart robots “Cobots” to save employees’ valuable time by leaving them free to focus on quality control and improving their know-how. They can perform multiple tasks, understand employees’ emotions and are based on artificial intelligence

Connected Products

L’Oréal creates more and more connected products thanks to the data it captures from its customers. This enables to make good make goods more traceable and thus the production process more transparent which is becoming increasingly important for customers. Moreover, having connected product facilitates the process of having a global vision of inventory. For example, their inventory drone Eyesee captures all their inventory in a time-efficient and accurate manner.

Key Takeaways

Customers want everything, anywhere, all the time. L’Oréal has understood that its operations & supply chain would drive all its business and the Group has done tremendous work to adapt its supply chain by basing it on Industry 4.0. Their 3 key areas are: Accelerated development to reduce time to market - their 3D printing prototyping and use of virtual reality has allowed L’Oréal not only to be much quicker in delivering new products but also to cut tremendous costs while maintaining their quality. Agile lines to go beyond to customers’ request - by using automated production lines and collaborative robots, L’Oréal is able to save time and dedicate it to more valuable activities. These product lines have also been adapted to manage final product differentiation and thus respond to the growing trend of mass-customizationInvesting in their current and future talents - L’Oréal understand that its people are its first asset. It dedicates a lot of resources to empower its employees through various training and by breaking down walls amongst departement. By fostering communication, more innovative ideas see the light and help the company to improve. Although L'Oréal is excelling in these areas, it faces some key challenges in regards to its operations & supply chain management:Connecting with Millennials - they represent a huge market but L'Oréal is struggling to connect with them because they are mostly online whereas L'Oréal does not have such a strong online presence. They have recently tried to recruit Millennial brand social media editors as a means to connect with other Millennials. This challenge is also in line with their difficulty to create a thorough omnichannel experience.Building a more sustainable supply chain - being environmentally friendly is a growing trend and L'Oréal must work on this. The first step is to adapt its production line by choosing raw materials that are more eco-friendly. L'Oréal recognises this challenge and states "we will empower every L'Oréal consumer to make sustainable consumption choices while enhancing the beauty of the planet."Employer reputation: Although L'Oréal invests a lot in its employees, over the years it has build a reputation of being a very tough place to work. Managers are often under great pleasure to deliver under short deadlines and not treated as they would hope for. L'Oréal work on its workplace environment: it is like with customers, it is very expensive to hire someone and much cheaper to work to make current employees happy so they deliver maximum results.To face these challenges and keep on going forward, I have 3 major recommendations:Build an omnichannel experience by collecting more data on consumers at all the touchpoint (all the steps of the customer journey). By combining all this data, L'Oréal would be able to make sure that consumers have a 360° homogeneous and top quality experience.Empower even more employees by getting them more involved and by listening to their suggestions more closely. To get them more involved, L'Oréal should apply Genchi Gembutsu to Go & See what is happening and check facts by themselves.Focus on building a sustainable value chain. Customers are discarding companies for their environmental & social impacts. To start with this, L'Oréal should focus on the origin of its materials so that they are respectful of the environment. As we saw during the Starbucks assignment, companies should use sustainable materials and focus on relying on renewable energy. Through operational innovation, L'Oréal will also be able to build a more sustainable value chain. L’Oréal needs to continuously invest a lot of money and energy in order to continuously be ahead of the game and deliver products faster without compromising quality. That’s because they truly believe that their customers are worth it.

Empowering talents

L’Oréal has a very strong employer branding and is able not only to attract many talents but also to help them excel in their job. This is at the foundation of L’Oréal’s success in operations & supply chain management and beyond.

Attracting new talents

Beyond its strong employer brand image, L’Oréal attracts future operations & supply chain managers current student by organizing student competitions such as its Supply Chain Hackathon called UNBOX SUPPLY CHAIN event. Their great marketing expertise and the award promised for the top 3 teams help attract many students. Check out the event teaser here

Training for success and rewarding excellence

L’Oréal’s Supply Chain is integrated and structured around the main sectors of business: the industrial logistics teams manage production scheduling, plant procurement and subcontracting and manage the warehouses of raw materials and packaging items.The international logistics teams oversee the synchronisation of the logistics chain and procurement flow management, manage the catalogue of products used in sales operations and coordinate product launches. Lastly the sales logistics teams manage demand, develop services for the group’s commercial partners and supply the retail outlets.” Each of these teams is granted regular training to keep improving their operations. This is how L’Oreal excels in this domain and gets award prizes such as the Operational Excellence Award in 2017.

aBreaking silos

L’Oréal put great emphasis on having its various departments communicate with one another. They achieve this by implementing the 5C’s model for breaking down silo organizations (Communication, Trust, Coordination, Common & Mutual knowledge and understanding and Cooperation). They even look for external resources to help them achieve this. For example, L’Oréal has partnered with startups to create the “HR disrupt café” where work related innovations are put together to improve work experiences and break silos -

a

Mass Customization & Postponement & personalization

L’Oréal has adapted its supply chain to respond efficiently to the growing desire of customers to have products that are only theirs. “We really need to be reactive and we really need to make sure we provide what consumers need,” Carlos Ruiz, Vice President of operations and head of North American manufacturing for L’Oréal. It is also a key way to create an emotional and intimate connection with the customers.

Mass - customization

Due to the increasing trend of mass-customization, the new production lines also have to be able to manage final product differentiation (shade, labelling, etc.) later in the value chain. It is important to make changing product formats more straightforward, which is a key aspect of flexibility. We can produce the base and then choose the color for a lipstick right at the very last moment”, explains Stéphane Lannuzel, Operations Chief Digital Officer. This is an example of transparent customization where the representation of the product does not change but the color of the lipstick makes it another product. To face this mass customisation, L'Oréal has developed the 3 main capabilities:Solution Space Development by identifying the product attributes along which customers diverge. Indeed, L'Oréal has developed innovation toolkit by enabling customers to scan their skin and create a product based on their skin type and preferences.Robust Process Design through flexible automation. As mentioned above, L'Oréal has been able to make product differentiation possible in the last steps on its production line so that it is easier & efficient to deal with. Choice navigation by offering assortment matching. A software makes recommendation to a customer based on what he has previously purchased and his preferences.

In-store personalization

With POS co-creation opportunities, consumers can manufacture their very own cosmetic products in-store or have a personal message engraved on their fragrance bottle. This is already happening in the USA and also in London, UK, with Lancôme’s Teint Particulier, where shoppers can use a customization service supported by a smart factory (called My Little Factory) right at the POS. A scanner detects the customers skin type and then the factory creates the perfect foundation with the appropriate colors given the customers’ preference. This is a great example of collaborative customization. The objective is to make this a large-scale personalization. Discover how it works by watching the video from min 3:57 to the end.

Delivering Excellent Service/ Customer experience

Since its creation, L’Oréal has been a customer-centric brand. “This means it’s really important that we deliver products fast, make the most of automation, and never compromise on quality.” Stéphane Lannuzel, Operations Chief Digital Officer.

Quality control & Regulations

To ensure delivering excellent service, L'Oréalmakes "100 quality controls for each one of their cosmetic products over the course of the production cycle, from design to sourcing of raw materials and packaging, manufacturing and distribution. We basically make sure that the product is perfect at every stage of production.” -100% of their plants manufacture in accordance with ISO 22716 for good manufacturing practices for cosmetic products90% of their plants manufacture in accordance to ISO 9001 for quality management Only 52 complaints per million products sold. L’Oréal’s excellence is revealed through in the feedback received from consumers. It handles all issues from the customers’ perspective. Kaizen activities are made based on feedback from customers. Feedback drives continuous improvement. Among the 8 dimensions of quality we covered in class, L’Oréal is very strong on the aesthetics of its products, their reliability and durability. This is one of the key reasons why customers are loyal and become brand ambassadors.

Instore experience

L’Oréal addresses very well all the stages of the customer journey map, especially it’s in-store experience.SimpliField - L’Oréal has partnered with SimpliField, a firm that offer a mobile solution for store and field team to create smarter execution processes and improve their performance with more predictive decisions from anywhere, in real time. By being "obsessive about the details" and "using consistent methodology" across their stores, (Schmitt 10 principle), they tear down silos between services and make sure everyone is on board and aligned to reach the level of excellence expected by customers. This solution has greatly improved the experience L’Oréal gives to its customers by meeting their expectations at every step of the process. RFDI technology (Radio Frequency Identification) - This technoloy enables L’Oréal to create more fluid experiences, simplify the path to purchases and the operational management of stores. For example, it has been applied in NYX stores. All the products were equipped with RFDI chips so they were easily identified and located. It also helps with inventory management. In this way, L'Oréal thinks about the user experience, well beyond the products themselves. According to the Schmitt 10 principle, L'Oréal's starting point is clearly the Customer Experience. Nonetheless, I believe the brand needs to improve the omnichannel experience it offers its customers. Indeed, L'Oréal only makes 11% of its total sales online and the online experience does not always continue seamless in the stores. This is partly due to the fact that some products are sold through distributors on whom they do not cannot have much influence in terms of layout & customer experience. By continuously improving all parts of the customer experience and by continuing to think in act in terms of the customer experience, L'Oréal will truly attain excellence in customer experience (10 lessons of delivering excellent service).