Gear Classification

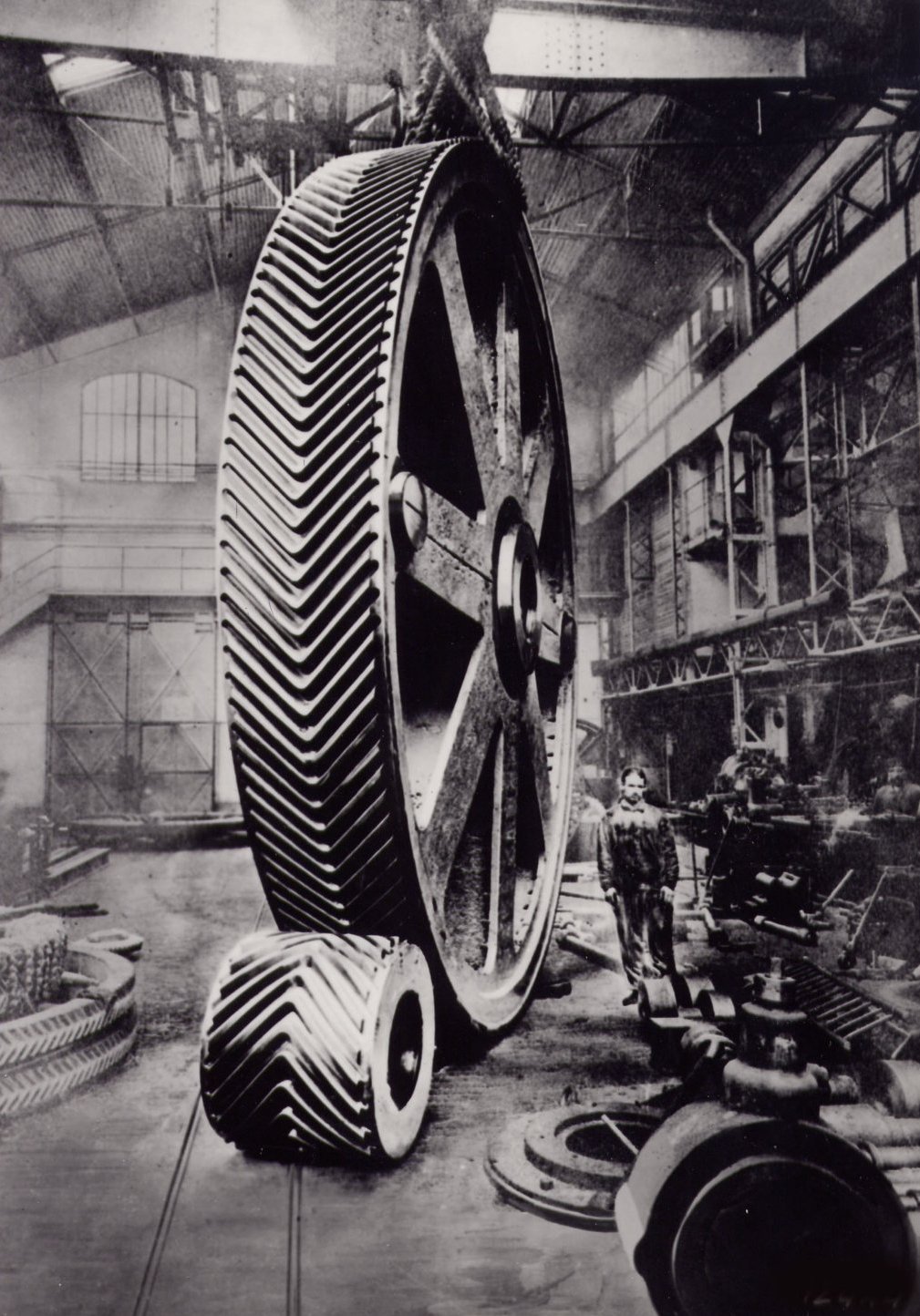

Herringbone gears:

Joining of two identical helical gears with opposite hand on the same shaft

Advantages

They have the advantage of transferring power smoothly and the side-thrust of one half is balanced by that of the other half

Disadvantages

Are more difficult to manufacture than equivalent spur or helical gears and more expensive and it cannot be cut by simple gear hobbing machines

Applications

Steam turbine

Power Transmissions

Special Gears

Worm and worm gear

Worm has only one tooth matched with the worm gear

Rack and pinion

Diameter of the wheel infinite

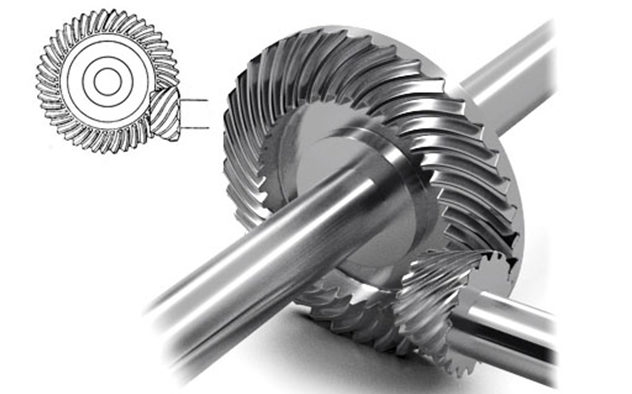

Bevel gears

Angle between the shafts (intersecting apices)

Hypoid gears

A hypoid is a type of spiral bevel gear whose axis does not intersect with the axis of the meshing gear

Spur gears

Are a type of cylindrical gear, with shafts that are parallel and coplanar, and teeth that are straight and oriented parallel to the shafts

Advantages

They are easy to manufacture and suitable for a wide range of applications and generally have high transmission efficiency

Disadvantages

The method of tooth meshing causes high stress on the gear teeth and high noise production, so they're typically used for lower speed applications

Applications

Ball mills

Crushing equipment

Home appliances

Helical gears

The teeth of a helical gear are set at an angle (relative to axis of the gear) and take the shape of a helix.

Advantages

They have less noise, especially at medium to high-speeds, less load on each individual tooth, a smoother transition of forces from one tooth to the next, so that vibrations, shock loads, and wear are reduced.

Disadvantages

The teeth causes sliding contact, which produces axial forces and heat, decreasing efficiency. And are more expensive.

Applications

Printing

Port and power industries

Rolling mills