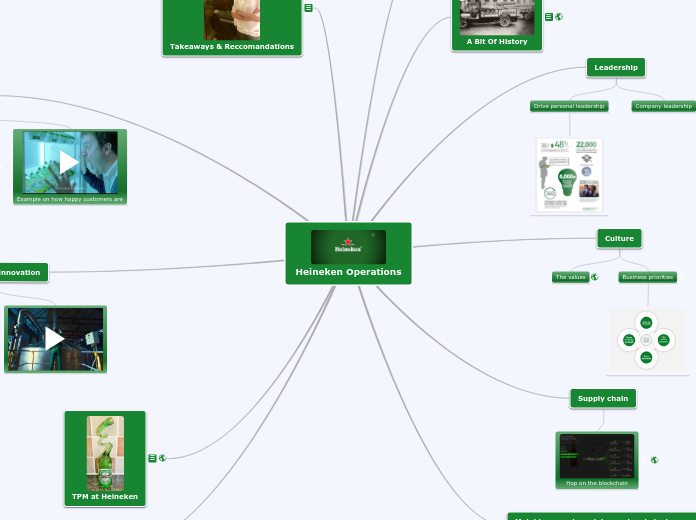

Heineken Operations

Introduction

Francesca MeucciOperation and Supply chain managementMIM, F1, Feb IntakeWhen I was 16 years old I went to Amsterdam and I visited the Heineken Experience Museum. I remember that I was fascinated by the explanations of the production process and all the work that was behind, what for me was a simple beer. So when I had to choose a topic I selected Heineken because I wanted to dig deeper into this old curiosity I had

A Bit Of History

The Heineken story began more than 150 years ago in 1864 when Gerard Adriaan Heineken acquired a small brewery in the heart of Amsterdam. Since then, four generations of the Heineken family have expanded the Heineken brand and the Company throughout Europe and the rest of the world.

aLeadership

Drive personal leadership

Heineken employs more than 85,000 people in over 70 countries. As our business continues to grow in scale and complexity, people are our main source of competitive advantage

Company leadership

Culture

The values

Business priorities

The Heineken strategy is built around four business priorities for action. They are designed to enable the Company to win in the marketplace, focus on the long-term sustainability of our business and continue to delivering growth and shareholder value.

Supply chain

Hop on the blockchain

Heineken developed a system to track its supply of hop thanks to blockchain. This can be considered as a great operational innovation because it allows the company to have a better view of its supply thanks to the new technology of blockchain. Besides, the company is also able to track its environmental footprint with the final goal to reduce it at a minimum.

aMatching supply and demand and stock managment

Heineken is adopting many new technologies, to keep improving its operations and to better forecast supply and demand. Here some examples

HOPS- Heineken Operational Planning System

Heineken USA launched its new Interact based system called Heineken Operational Planning System (HOPS) to allow the parent company to produce the beer closer to the time when they need to deliver it, so the customer receives a fresher product. The new system enables Heineken USA to achieve 50% reduction in the lead-time from order to delivery, 10% increase in sales and a decrease in inventory levels.

Every Angle at Heineken

This case represents another example of how Heineken uses new technology to improve its stock management

S&OP core programme

Takeaways & Reccomandations

After doing this Mindmap about Heineken, I discovered that this company keeps on innovating in every way they can. Since, as the CEO stated, beer as a product has very little space of innovation, the company is doing great in changing and improving his operations thanks to new technologies and management practices.I was personally impressed while digging deeper into the operations of the company, by the varieties of operational tools that they adopt as well as the new ones that they have created to be the best at what they do.I think that this company is doing very good, and in the future will have a strong competitive advantage over its competitors because these practices in the future will become the base of a business and not anymore something to do better.The only recommendation I can have for this company is to communicate in a more effective way its innovations, this because for the customer can be interesting to know how much the company is doing in ordered to be the best brewery in the world.

Customer experience

Big Data and AI to Improve CX

Heineken manages to improve its operations through data analytics. These new technologies also help the company to improve the customer experience as it will be described in the article

Heineken experience

As Disney has Disneyland, Heineken has Heineken experience. It is based in Amsterdam and is a sort of museum, which guides you through the history of the company together with the operations made to produce one of the most famous beers in the world.PS: It also includes a tasting of the beer at every stage of production ;)

Example on how happy customers are

Operational innovation

Heineken is a customer-centric company and is amazing how the managed to innovate their operations and product thanks to the suggestions of the customers. In the link, some of the best ideas selected by the company

TPM at Heineken

Lean management, Kaizen or Bottleneck analysis at Heineken are basic procedures to keep on improving their operations. In one of their production plan in 2009, as the first brewery of Heineken, they have received an international accreditation from the Japan Institute of Plant Maintenance for its Total Productive Maintenance program.Here the article that talks about it

aSustainability

Heineken believes that the key to be sustainable is to start from its operations, therefore we can see on the website that they try to reduce their consumptions under many aspects and with fixed goals

"We aim to use our global business as a positive force for change. Brewing a Better World is our global sustainability strategy that unites all our operating companies behind this goal."