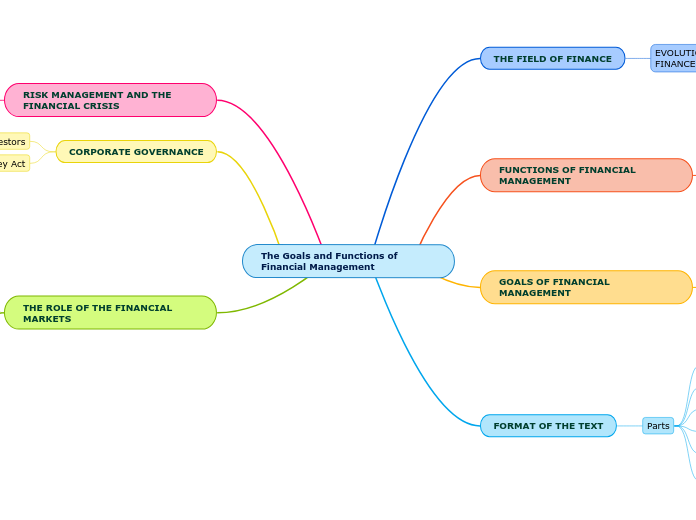

Clothing

Quaternary Industry

A job that may be linked to clothing could be a high demand for personel using ecofriendly material; Organic Cotton

Benefits of organic cotton

Preserves soil quality and limits soil erosion.

This type of soil could still germinate even if there's a massive drought in a particular area.

Promotes and advances biodiversity; Organic cotton is proven to produce 94% less of greenhouse gasses than harvested cotton. This promotes biodiversity by preventing massive chaos, such as rising sea levels. Rising sea levels could destroy the habitats of animals and homes.

Sustainable; uses less energy, releases less greenhouse gasses. Duriing the process of germination and harvestation, organic cotton is said to use less water.

Many fashion designs company in Eupa would like to customize their designs in order to fit their climate and future goals.

Tertiary Industry

Examples of jobs that require selling clothing are thrift stores GoodWill, OldNavy and Roots.

To ship to stores; wrap the clothing or accessory in a sizable plastic bag. Next, package the entire shipping into a poly mailer.

Examples are Rugs, blankets, shoes (inside) , Winter clothing, and cotton balls to clean up wounds.

Comes in the market for adults and kids to buy. It's also used as beds and comfort for those who don't want to feel cold.

Fashion designer

Once, the sketches are sent to a seamstress, the final product is made. From there, it can appear in fashion shows like-Zara, Nike, H&M.

Fashion designers sketches designs of clothing, footwear and accessories.

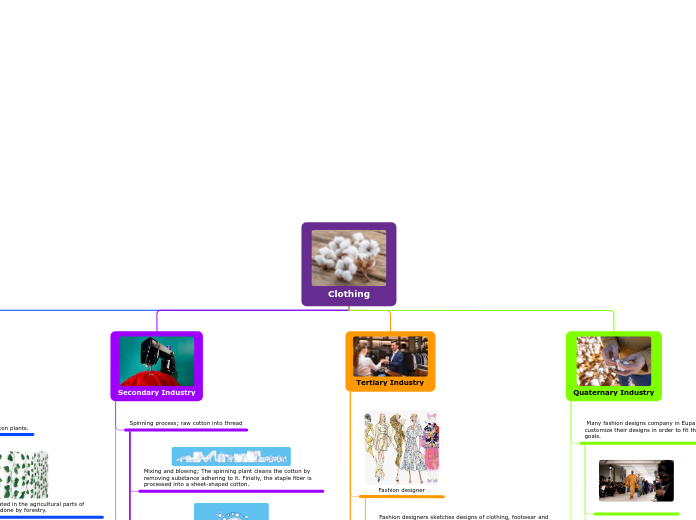

Secondary Industry

Weaving Process;thread into fabric

Product; The finished pant is sold.

Packing; The pant is packed in a manner appropriate to Eupas shipping conditions.

Inspection/ Folding;The fabric is inspected and folded. Imperfections are corrected as required. The fabric is then graded.

Weaving; Prepared beams are set on a looming frame to weave a textile in the following five motions:

(5) Take-up: The woven fabric is wound on the cloth beam.

(4) Let-off: The warp yarns are unwound from the warp beam.

(3) Beat-up: Pushing the newly inserted yarn back into the fell using reed.

(2)Picking: The weft is inserted between two groups of warps.

(1) Shedding: two groups of warps are opened to let the weft pass through.

Drawing-in; To prepare for setting beams on a loom, warps are routed in the order of droppers, healds and guide bars.

Sizing; The warping beams of the required number of warps of the final textile are piled up for rewinding on beams after sizing and drying.

Warping; cones are set on a warping machine to wind the determined length and number of yarns onto the number of warping beams under tension.

Spinning process; raw cotton into thread

Winding; rewinding the finished yarn onto bobbins into the cheese or cone according to its piece of clothing, which in this case, is a pant.

Spinning; when spinning the yarn. The yarn would like to have it's desired thickness and length

Roven;Twisting is first applied to fibers in this process to obtain the colored yarn, which is wound onto a bobbin.

Drawing; using a drawing machine to straighten the fibers. This process transforms fibers into string-like piece called "drawn sliver."

Combing; The silver lap is then combed to remove fine dust and small particles of fiber

Silver lap former; From 18 to 24 carded slivers are fed together side by side. They are drafted and a loose form of web is created. The web is rolled up to a lap called "sliver lap."

Carding; The fibers are then neatly combed so that fine dirt could be removed.

Mixing and blowing; The spinning plant cleans the cotton by removing substance adhering to it. Finally, the staple fiber is processed into a sheet-shaped cotton.

Primary Industry

Agriculture; Most cotton in Eupa is grown in fields, during a spinning process. And is extracted by a picker or a stripper.

This extracted part is then inserted into a harvester.

A cotton stripper pulls the white part (boll) entirely off of the cotton plant.

Clothing in Eupa comes from cotton plants.

Cotton fibers comes from cotton plants which germinate during the spring/summer season.

These cotton plants are located in the agricultural parts of Eupa. Some of the rest are done by forestry.