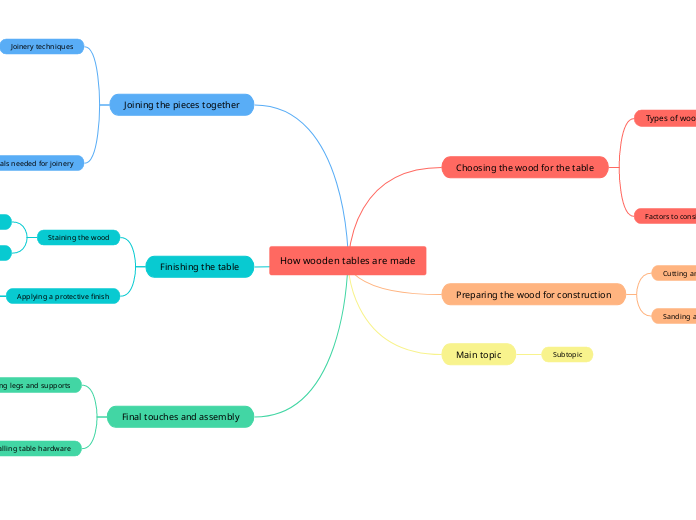

How wooden tables are made

Final touches and assembly

Installing table hardware

Tabletop fasteners

Hinges

Drawer pulls

Attaching legs and supports

Techniques for attaching legs

Types of table legs

Cabriole legs

Straight legs

Tapered legs

Finishing the table

Applying a protective finish

Wax

Lacquer

Varnish

Staining the wood

Techniques for applying stain

Types of wood stain

Water-based stain

Oil-based stain

Joining the pieces together

Tools and materials needed for joinery

Screws or nails

Wood glue

Clamps

Joinery techniques

Butt joint

Dovetail

Mortise and tenon

Benefits of using this technique

How it works

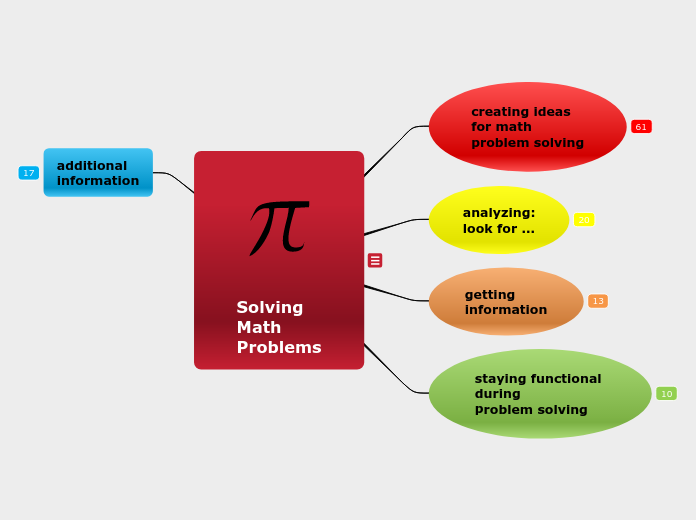

Main topic

Subtopic

Preparing the wood for construction

Sanding and smoothing the wood

Techniques for sanding and smoothing

Importance of sanding

Cutting and shaping the wood

Techniques for cutting and shaping

Tools used for cutting and shaping

Choosing the wood for the table

Factors to consider when selecting wood

Color

Grain pattern

Durability

Types of wood commonly used for tables

Walnut

Benefits of using walnut for tables

Characteristics of walnut wood

Maple

Benefits of using maple for tables

Characteristics of maple wood

Oak

Benefits of using oak for tables

Characteristics of oak wood