A recommendation, almost all elements, videos, photos, and texts have a written description, but sometimes it is not immediately shown on the right. You have to search with the mouse the symbol on the right and click it.

Have fun!

2019 Christmas Company Party

It is incredible to think how this whole world of relationships and progress was created in just 50 years by one man, born an orphan.

This is also why I chose this topic for my mind map, because it makes me think about how infinite human possibilities are.

I hope you enjoyed this travel!

Thank you!

Federico Cerri S2

References

http://www.luxottica.com/en;

https://www.mckinsey.com/business-functions/digital-mckinsey/our-insights/transforming-operationsmanagement-for-a-digital-world; http://www.luxottica.com/en/governance;

https://onesight.org;

Scientific paper of sector, “Asta La Vista”, Luxottica Operations Management;

LUXOTTICA

IE Business School

Master in Management - Class of September 2019

Operations and Supply Chain Management - Prof. Felipe Quintana

Section 2

Federico Cerri

Why LUXOTTICA?

I have chosen to present you LUXOTTICA as the object of my mind map. The reason for this choice is that I consider the company to be the largest Italian company of our days, which has managed to conquer, in a short time, the world market, through its focus on quality and efficiency, while maintaining its Italian roots.

The company was the first in its market to undergo a successful process of digital transformation, that allowed the firm to become more interconnected and agile, giving her the chance to become the global leader it is now.

I think it is an excellent example of how excellence in supply management allows us to emerge among our competitors and become market leaders. In fact, Luxottica was only born after its main competitors, who were already solid in the market, but thanks to its disruptive innovations it managed to reach the dominant position.

Moreover, I had the opportunity to do a summer internship at the Agordo headquarters, where production is still based. During those three months I was completely absorbed by the beauty of the place, the work done there and my colleagues that I can now call friends and after that period I am proud to declare myself a Luxottican!

That's Me! You can also detect a pair of Ray Ban Aviator...

In the middle of the courtyard there is a giant statue of the pair of glasses symbol of Luxottica, the one that decreed its success, the timeless Ray Ban Aviator.

Picture of the company, from my first day of work

Digital Transformation

Digital transformation is the leading phenomenon of our century, a revolution that will involve all our existences, from the Macro to the micro environment. It represents a radical change in the way we conceive and live our life; this phenomenon has already become established as part of our daily routine, from the instinctive action of checking the news and e-mails on our smart-phones as soon as we wake up to its role in business.

This phenomenon has embraced the corporative world entirely, and its nature of being a managing tool, with a sensible organizing power, has led to its deep penetration in the operations’ areas of businesses. This power has been largely applied to supply chain and strategic planning, to innovate companies’ organizational strategies. In a world where being fast, efficient and effective no longer represents a competitive advantage but only a hygiene factor, embracing the digital revolution is now a must-step in the path of value creation.

The main opportunity offered by digital innovation is freeing human resources from the repetitive tasks of their jobs, allowing them to allocate their time on decision making and problem solving.

Entrusting the redundant and practical parts of operations to algorithms able to provide an omnicomprensive scenario of the company’s necessities and capabilities, produce a double benefit.

On one hand allows the human component to focus more on the strategical side of his job.

While, on the other, provides a wider and more accurate supply of datas.

To follow this path of growth Luxottica has developed the so called “NPS”, New Planning System. In order to maintain its leading role in the market the company equipped itself with management software, such as SAP and YUNGO, through which it has managed to create a perfect connection between the various operating units and to achieve homogeneity in operational processes across the world.

Luxottica has already achieved one of its goals, the strong integration of physical and informative streams.

The effort put in the digitalization process was triggered by the necessity of making Luxottica more integrated and connected all over the world. In fact, although being a global company with an international presence, the firm administrative headquarter is still where the company was born almost 60 years ago, in Agordo, a small village embedded in the Dolomites. The particular location of the headquarter has made the availability of real-time information and the interconnection with all production processes around the world vital for the survival of the company.

Indeed, Luxottica can boasts to be one of the biggest company in the world with a strong vertical integration, with almost 96% of the manufacturing and organizing operations carried out inside the firm.

Moreover, to improve speed, flexibility, quality and productivity, Luxottica has incorporated robotics, automation, computing and big data into its manufacturing processes. The Group is tirelessly committed to operational excellence, tapping into new technologies and digital tools to achieve a higher level of factory digitalization. The Group has also accelerated its Digital Transformation Program in order to identify manufacturing needs earlier and monitor real-time production data, improve work and personal safety and allow teams to solve problems faster and more proactively than ever before.

Robotic Logistic

In 2018 the pilot project for the introduction of the Internet of Things in the field of logistics was launched, entrusting the identification, picking and transport of products in warehouses to fleets of conveyor robots.

Launched at the pilot site of Rovereto, the project has subsequently taken off in the other Italian plants, making it possible to obtain an accurate and efficient warehouse management through the real-time connection between the robot fleets and the company's Master Data System. The support of the robotic fleet has made it possible to reduce the time wasted by individuals, for the unused talent, following the six sigma principle, now the warehouse staff can make greater use of their talent for planning inflows and outflows more precisely, as well as to follow projects for the implementation of robotic fleets in the plants abroad.

Entrusting warehouse and stock logistics to the machines has made it possible to reduce management errors in terms of time and space, improving efficiency by reducing errors, a true example of Lean Management.

What does it means for customers and buyers?

As we have seen in Session 12, Delivering Excellent Service.

As a highly vertically integrated company, the digital transformation process is carried out in every area of the operations and supply chain. In this case we see how the distribution and sale of glasses is digitalized, in order to make the experience more agile and fun for both operators and customers.

This digitisation process will be made available to b2b customers, i.e. eyewear shops and opticians, in order to create a fully digitised supply chain.

Stores will be equipped with sensors that will be able to understand the customer's tastes and provide him with virtually all the models of glasses in the company's product portfolio, even those that are not currently available in stock.

The customization of the experience will play a major role, with the creation of devices that will allow customers to customize lenses and frames for real-time interaction.

This corporate project, which saw developments in the first quarter of 2019, will allow Luxottica to equip its single-brand stores with 20,000 digital screens that will replace the old form of advertising panels. The modernization costs will be borne in full by the company, in a strategy of strengthening relations with distributors, who represent the outflow part of the supply chain. In this perspective, we can resume the third A of triple A management of supply chain, Alignment. Bringing the interests of the company and its partners closer together aims to strengthen existing synergies to give further impetus to the group.

MIDO Eyewear Fairs 2019

Presentation to the public of the new smart-store concept that will be proposed to B2B customers.

OneSight

The company has always been very attentive to the health of individuals, and strives to pursue excellence in the eye care field. This is why it has joined the OneSight project.

OneSight is an independent, non-profit organization that provides access to quality eye care and eyewear to less developed communities around the world. Its mission is to combat the global eye care crisis, a problem that affects more than a billion people who could solve their vision problems simply with an eye exam and a pair of glasses.

Luxottica, being the leading eyewear and eye care group wants to be the forefront of the challenge to improve the quality of vision worldwide.

That's why the Group is proud to be the supporter of OneSight, with a contribution not only in monetary terms, but also expressed through effort of many employees, who take part in many of the organization's activities, encouraged by the company to make their highly specialized skills and expertise available to the rest of the world.

The commitment of the entire Group enables OneSight to sustainably provide quality eyewear and eye care to less privileged communities around the world each year.

Luxottica's association to this valuable initiative also serves as an internal alignment mechanism within the Group. Employees and partners are in fact advised to take part in these initiatives, not only financially but also personally, exchanging their knowledge with developing countries and communities to facilitate their growth. This initiative has received an excellent response from all the corporate stakeholders involved, who have enthusiastically embraced the project. This has made everyone feel more motivated and close to the company's values, increasing loyalty and commitment, attention and commitment also increases in the workplace, and work proceeds more efficiently in the workplace.

Master Data System

Related to the concepts viewed in Session 11, Breaking Business Silos, Aligning Operations with the other relevant Areas of the Organization.

Launch of the NPS, New Planning System. Structure of the Digital Revolution.

The digital revolution process took place on the creation of an organic and dynamic digital structure, characterized by a Master Data system, formed by six components, each of which represents a branch of the planning division or plays a supportive role. The Master Data presents:

1. Two software products that operate in the organization of demand planning:

- A “DPM”, a software that carries out statistical analysis and computations in order to perform the function of the MPS, Master Production Scheduling, unit of the planning, providing the 90% of the whole company’s forecast regarding distribution. The DPM analyse the two main distribution channels of Luxottica, the whole sail and the retail, performing the function of monitoring and providing information about the demand that absorbs 90% of the company’s output.

- A "SAP”, an E.R.P, “Enterprise Production Planning” system, which focuses itself on the remaining 10% of the company’s forecast, that is composed by the so-called “Made to Order”, MtO, special orders that do not re-enter in the normal production schedule of the firm. This is composed by particular kind of products which are directly ordered by fashion houses, such as Prada or Armani, for catwalks or under the request of customers of particular importance. SAP software divides the MtO in two additional categories in order to provide a more accurate analysis, Light or Hard orders, the hard are the ones characterized by incredibly high levels of customization, that made them particularly difficult to handle.

2.“S&OP a management software for indirect plans of productions.

3. A program that plays the function of calculating and defining all the production constraints and possible inconvenients that may occur during the various phases of the product life cycle. This allows the company to provide its planners with a 360-degree scenario of which emergencies they might have to handle in the future and which capacity limits they have to take into account while elaborating strategic decisions.

4. All the information provided by these four operating systems merge into the “12-JDA”, a digital SCP, “Supply Chain Planner”, that represent the “beating hearth” of the whole Master Data, this system in fact operates the function of join together all the data provided to it and elaborate them in terms of actions that have to be taken in order to fulfil the market demand of products, and the amount of resources necessaries to the company to satisfy it.

5. All the now elaborated data are converted in terms of purchase and order proposals. Datas, now modelled in this form, are sent to the last and more practical component of the Master Data, a second SAP software that plays the role of a data bank, providing planners, with the exact amount of input that have to be reached per single article code, from the number of screws to the tons of steel needed, in order to keep the global production going. Now human rationality enters in the game, in fact, the planner has to elaborate all the data provided and issue, trough the direct and inter-personal contact with various units responsible, orders of production and purchase.

This ambitious progect set itself 4 main goals:

- Refine Integration

- Reduce Complexity

- Improve Centralization

- Improve misurment of Loading Level

Level of Loading

The Level Loading, i.e. the balancing between implants’ capacity and stock’s level. Being able to reach an equilibrium in workload distribution between various implants is fundamental in a business like the eyewear one, that is strongly under the influence of fashion trends, that led to the application of a product life cycle that is dynamic and fastchange oriented, and stagionality.

Flexible Centralization Process

The centralization of the informative flows related to the MPS, “Master Production Scheduling”. This will allow to join all the production requests that are now divided per manufacturing implant, in a single data center, that will allow the management to have an clearer overall vision of the whole group.

Reduction of Complexity

Reduction of Complexity, in fact as it is possible to assume from previous paragraphs, the company’s employees have to manage the organization of dozens of thousands article codes, each characterized by its own complexity and characteristics.

An impressive amount of information, too big to be managed in all its single parts. This has been one of the first problems addressed through the implementation of the digital revolution.

Thanks to the NPS project, the process of data research and organization carried out by SAP, has been put in constant communication with the JDA, that have elaborated all the information provided, founding relations and similarities between all the codes that have allowed the program to create various clusters in which different codes, that from the human point of view presented no connections at all, can be gathered together in order to manage them as group, as cluster, sensibly simplifying the planner’s job, that now has to face at maximum a hundred of clusters and no more dozens thousands of single article codes.

Integration

Integration, in terms of perfect coordination between the planned demand of final products and the balancing of the group’s industries’ capacity and productivity potential, the current and the future’s one.

Luxottica is a manufacturing company, everything that supports production scheduling can give immediate business advantages and since before it was based on many different systems, it was important to create an interconnected system.

In the Supply Chain the management of "physical" and information flows is now strongly integrated.

Every year the company introduces 10 thousand new Sku (singular key unit), and manage more than 25 thousand purchased components, 20 thousand production Sku, 70 thousand active Sku in stock, and seven different business models.

As we can guess, achieving the integration of these flows was fundamental in order to limit inefficiencies and make the company agile, able to adapt quickly to possible emergencies or changes in supply and demand.

Corporate Social Responsability

As seen during our field experience, the Starbucks analysis, in session 18, creating a strong corporate culture brings significant benefits in terms of employee turnover and training costs.

The company has always been interested in sustainable development, both on a human and environmental level, this is reflected in the relationship with employees, who call themselves a large family, and in measures to reduce the environmental footprint, in the field of operations.

The eyewear created by Luxottica has an intrinsic social purpose: that of helping people to see.

Making the best eyewear in the world, innovative in design and excellent in quality, represents the intersection between the Group’s Sustainability vision, “To see the beauty of life”, and its mission: the health and well-being of the eyes.

Thanks to “made in Luxottica” eyewear people can enjoy the beauty of life in every aspect and of the world.

The Group’s distinctive, vertically integrated business model enables Luxottica to oversee the entire value chain. This guaranteed control of all phases and enables it to closely monitor environmental issues, health and safety and human rights along the value chain and, ultimately, to adopt socially responsible practices.

Sustainability along the Supply Chain

Related with the Starbucks analysis, in session 18.

In addition to outward-looking commitment, the company knows that to improve things you have to start from the inside. This is why managing a sustainable supply chain has always been one of the Group's primary concerns.

Over the years, numerous initiatives have been taken to pursue the objective of an operations system that follows the principles of CSR.

Monitoring and compliance by an external authority to pass the selection process to become a supplier to the company. Aiming for excellence. Luxottica engages a qualified third party to monitor the suppliers’ compliance with ethical principles and environmental and social responsibilities, as well as to implement corrective actions in the event of noncompliance with the Group Code of Ethics and local regulations. Moreover, in 2018, Luxottica launched a training workshop on responsible sourcing for strategic suppliers. China was the first geographic area to be involved due to its high-risk profile and the amount of purchases made by the Group, which in China produces over 40% of its frames and sunglasses.

The total consumption of energy deriving from non-renewable resources can mainly be attributed to the consumption of grid electricity and, to a lesser extent, the consumption of natural gas and diesel used to heat the production and logistics sites within the reporting scope. Meanwhile, the total consumption of renewable energy is connected with hot water from biomass and electricity from photovoltaic energy and refers exclusively to the Italian sites.

Digital Transformation has caused the Group's energy consumption to increase, even in 2018 the general increase in energy consumption in the Operations (+2.3% to 389.1 kWh at constant scope) . The digital transformation of the company has made possible greater communication and connection between the various business units, this has resulted in the possibility of further increasing vertical integration and the opening of new international hubs. This has resulted in an increase in energy consumption. Thus, since 2013, Luxottica has been investing in manufacturing plants that run on renewable energy, with the objective of reducing its Carbon footprint across the value chain.

- The first one was the solar panel system in the Lauriano factory. Between 2014 and 2018, approximately 2,000 sqm of solar panels, allow the firm to reduce emissions by approximately 80 t/CO2 per year.

- 2014, the first biomass heating system was built in the Cencenighe factory.

- In July 2016, the solid biomass fueled trigeneration system next to the Agordo factory was started, the system is able to satisfy 40% of the heating requirements and 60% of cooling requirements within the factory.

- In 2018 Luxottica activated a solar thermal plant for the production of hot water at the Chinese production site.

The successful implementation of these green energy sources has brought the company to quadruple in a 4 years interval its quota of clean energy which, which is self-generated.

The company's focus on reducing its environmental impact has led to a virtuous path of conversion of the energy resources used, which in the medium to long term will ensure greater savings against the initial investments made.

The Master Data System has also been applied to reduce the company's emissions by creating a series of indicators that measure the company's level of service and linkage on a global scale.

The first phase of the project, started in 2017, quantified the emissions deriving from the transport of finished products among the primary distribution centers of Sedico, Atlanta, Dongguan and Jundiaì.

Subsequently, the scope of analysis was extended, the second phase of the project to quantify CO2 emissions from the transport of finished products (eyewear) considers all the distribution channels used to reach the final consumers.

The final consequence of this process was that the perimeter of analysis was extended to the entire path of each product, monitoring the consumption so that the MDS was able to track the position of each load in real time. This made it possible to identify errors, inefficiencies and pain points in transport and logistics, as each Hub was now able to track each individual load and have a complete overview of the company's transport flow. Therefore, the company's initial investment in the environment has had the result of increasing control over its supply chain, making it more efficient and reducing costs, thanks to the greater centralized control guaranteed by the New Planning System.

History

Welcome to this mind map, it is about Luxottica, the biggest player in the eyewear industry.Even if this name does not ring a bell I am sure you've already had a pair of glasses made by them before in your life.

Click on the link on the right to learn about the company's history and start this journey discovering a company that in the last 50 years has managed to produce all the glasses we all love.

OPERATIONS & LOGISTIC OVERVIEW

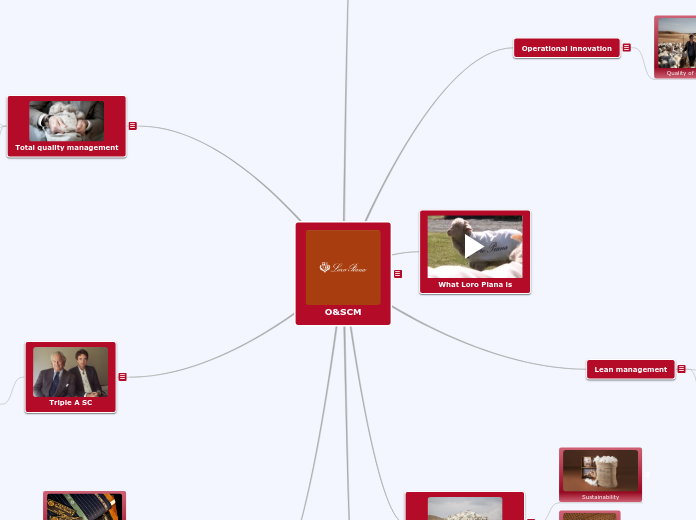

Alignment & Suppliers' Management

The objective of alignment is to bring partners, downstream and upstream, closer together in order to present themselves on the market as a compact team, almost as a single entity, in order to strengthen the business capabilities and strengthen the supply chain.

Given the high level of vertical integration achieved by the company, the issue of alignment could be considered marginal, but this is not the case, as supplier management plays a major role in the company's business plans.

The company works with around 2000 suppliers.

It is true that the Group needs to find excellent raw material and components producers or service providers, but it is also true that its dimensions and production volumes have reached a dimension that do not let suppliers to have a strong bargaining power. Despite this, Luxottica has always prefered to create synergies with its partners instead of imposing orders.

This has led to the establishment of decades-long relationships between the company and its partners, which have led to the formation of an important capital of trust.

It is precisely on this trust that the strategies that the Group applies today to improve the performance of its partners and maximise its network of suppliers have been created.

- Using the Jungo platform, which allows the order to be sent to the supplier in real time, at this point the order can be accepted or modified, if the required quantity or timing cannot be reached, a continuous correction between supplier and company in real time of the order begins. This allows to solve ex-ante and within a few hours any pain points of the process.

- Creation of Luxottica warehouses within the suppliers themselves, these warehouses function like real company warehouses, as they are used to stock products requested by the company, so that they can meet sudden peaks in demand for materials. Should sudden changes in demand occur, materials can be transported within a few minutes from the supplier to the company and vice versa. This also allows the company to lighten its warehouses, both from an operational point of view, further increasing capacity and from an accounting point of view.

- In order to increase performance and guarantee maximum punctuality, every year the company puts all its suppliers, divided according to the various product or component clusters, in competition with each other, and the following year orders are placed according to the positioning in the previous year's competition. This ensures that suppliers are able to meet the company's needs, as many medium-sized companies have created their fortunes thanks to Luxottica.

In addition, the company's ongoing commitment to sustainable development, pursuing the path of CSR, means that suppliers also find themselves involved in a path of value creation, and embrace its values.

In this way, suppliers know that by becoming part of the Luxottica universe they are embracing more than just one company project, they are also pursuing its human and environmental development values and objectives. This can be considered a further practice of bringing the Group and its suppliers closer together, who thus find themselves united in a mission of social responsibility, not only in the pursuit of profit. This creates an additional screening mechanism in the selection process, and only suppliers who are aligned at the level of values fell the need to continue the partnership. This allows the company to choose from a range of motivated, selected and compliant suppliers, significantly reducing future replacement costs that could be created by choosing the wrong supplier.

Triple A Supply Chain

As analyzed in class on the 13th of January 13, session 17, the Amazon Case, nowadays being efficient and having decent cost control is no longer sufficient to remain competitive in the market.

The total focus on speed and cost management makes the supply chain rigid and often unable to quickly respond to new challenges in the market.

A company's supply chain must be fast, efficient and able to control costs, but it must also be able to respond quickly to market stimuli and adapt to them. Doing this alone may seem impossible, in fact supply chain is a constant teamwork with suppliers and B2B customers, who have to work together with their partners to best serve the end customer.

From this new vision of operations comes triple A supply management, based on Agility, Adaptability and Alignment.

Luxottica in the world

Among Luxottica's strengths, its diversified and widespread geographical presence in over 150 countries worldwide, which includes institutional offices and wholesale branches.

The company can boast::

- 9,100 retail network outlets

- 13 distribution centres

- 13 production plants

Its presence across the world enables it to efficiently manage its inbound and outbound supply chain, strengthening economies of scale and scope on the one hand and penetration into target markets on the other, allowing it to benefit from the advantages offered by Glocalization.

In other words, the standardization and cost control of a global holding company and the flexibility and contact with the customer offered by a reality well rooted in the territory.

This expansion and the necessary cordination to keep it efficient is ensured by digital link systems, which guarantee a constant flow of information to all the company's hubs.

Adapatbility

Luxottica's adaptability lies in the international scale of its supply chain.

The Firm distribution system is globally integrated and supplied by the MDS, the centralized programming platform.

The company, even before the digital revolution, had an international network of supply and manufacturing points, the real strength lies in the link that has been created between them.

The network linking the logistics and sales centres to the production facilities in Italy, China, the United States and Brazil also provides daily monitoring of global sales performance and inventory levels so that manufacturing resources can be programmed and warehouse stocks re-allocated to meet local market demand. This integrated system serves both the retail and wholesale businesses and is one of the most efficient and advanced logistics system in the industry with 18 distribution centres worldwide, including 11 in the Americas, 5 in the Asia-Pacific region and 2 in Europe, which have allowed the Group to reduce worldwide logistic lead time year after year. The Luxottica’s logistic network is composed by two extremely integrated segments. The first one is composed by the three main distribution hubs located in strategic markets: Sedico (Italy), Ontario (US) and Dongguan (China). They operate as centralized facilities thanks to a highly automated order management system, servicing other Group distribution centres or, in some markets, shipping products directly to customers, thereby further reducing delivery times and keeping stock levels low. The second echelon consists instead in 15 secondary distribution centres spread all over the world.

The coverage offered by the group's galaxy of hubs, and the constant connection between them, allows the company to adapt its offer to every possible shock or change in the market, managing to maintain its efficiency and flexibility, and above all to always satisfy customers.

Agility

Agility lies in a company's ability to respond quickly to changes in market, demand and supply. For a company like Luxottica, which operates in the fashion and eyewear industry, it is subject to phenomena such as new fashion trends, the seasonality of products and the demands of designers and fashion houses, being able to quickly adjust its products' offer is vital to remain competitive.

Thus, the company has decided to move from being a trend seeker to a trend maker.

In order to achieve this ambitious goal and to anticipate market trends or shocks, and respond appropriately, the company has implemented some changes in its operations' managements.

Key to this change was the digital revolution experienced by the company.

Through the full integration of physical and IT flows, the company's forecasting departments are now able to have a 360-degree view of the current situation of the company, of every plant, distribution center or store, worldwide, from Rio de Janeiro to Shanghai. This has made it possible to precisely identify the daily requirements of each plant, and to monitor its working and loading capacity per minute.

The first phase of forecasting is carried out by the system, which on the basis of the historical and current stock, elaborates a first model of procurement requirements, which is then checked by the analysts, approved and sent in order, all this takes place every morning. The system is also able to learn from the mistakes made, and adjust its calculations accordingly, thanks to the experience gained.

The new connection system has also made possible greater integration among the company's employees, in order to spread the company's know-how, the company's real valuable resource, from one corner of the globe to another. In this way, the knowledge and experience of the company's various facilities are fully integrated and made available to everyone.

Therefore, possible pain points or errors are quickly identified and resolved.

In addition, in order to anticipate market demands, the models of future glasses are prepared in a time horizon of two seasons ahead, so that at the right time the models are reviewed and improved, according to the trends of the moment, but not created from scratch.

An agility tool is the continuous contact with suppliers and B2B customers, several meetings are organized weekly, in which the company explains the idea behind the new product or project they are proposing and all together they analise strengths and weaknesses of the idea, thus allowing to launch safe bets on the market.