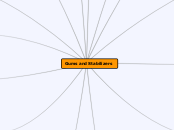

Gums and Stabilizers

Cellulose Derivatives

Use in fried foods in which they create

a barrier to oil absorption, retard loss of

moisture & improve adhesion of batter

Methylcellulose (MC) & HPMC gel when

heated & return to their original liquid

viscosities when cooled

Use for thickening, suspending,

stabilizing & modify flow characteristics

Very clear solution & stable over pH 4

to 10

Examples: carboxymethylcellulose

(CMC), hydroxypropylmethylcellulose

(HPMC)

Source of Raw Materials

peel of citrus fruits (lemon,

lime, orange) or apple pomace

Konjac Glucomannan

Armophophallus konjac, K. Koch tuber

Seed of Carob Bean

Carragenan

Seaweed

Acacia Senegal L

Main Classes of Hydrocolloids

Extract from plant parts

Extract from tubers

Microbial gums

Extract from seaweeds

Extract from seed

Derivatives from exudation or sap of

trees

Factors Affect Gum Properties

Distribution of Side Chains

Number of Side Chains

Type of Side Chains

Monosaccharide Composition

Molecular Weight

Hydrocolloid Structure

Substituent will determine whether

the gums are non-ionic or ionic (there

are no cationic food gums)

High MW polymers consisting long chain sugar units with substituent protruding from the main chain

Gellation of Hydrocolloids

Others will form gel under acidic

pH + high sugar concentration,

some require pH and alkaline pH.

Some hydrocolloids form gel on

heating/cooling; some require the

presence of cations

Thermally Irreversible Gelling Agents

Examples: alginate, starch, konjac,

HM pectin

Thermoreversible Gelling Agents

Examples: Gelatin, agar, -

carrageenan, -carrageenan, LM

pectin, gellan gum, methyl cellulose,

HPMC.

Gel formed on heating or cooling and

the process is reversible

What is Hydrocolloids?

Functions

Secondary Functions

Formation of Film

Encapsulation

Control of Crystallization

Suspension of particulates

Stabilisation of emulsions

Primary Functions

Gelling or texturizing agents

Thickening agents

Food Hydrocolloids

A range of polyssacharides and proteins also known as 'water-soluble gum', 'stabilizers' , 'gums'

Xanthan Gum

Use for thickening, suspending and stabilizing effects

Pseudoplastic – thin with shear recover their initial viscosity when shearing stops – important for good flavour release, mouthfeel.

Viscosity remain unchanged across the

temp range of 0 – 100 C & pH 1 – 13

Excellent stability to heat & pH

Completely soluble in cold water and hot water produce high viscosity at low conc.

Cellulosic backbone with trisaccharide

branches attached to every other

glucose unit in the main chain

Polysaccharides produced from fermentation of CHO substrate with Xanthomonas campestris

Guar Gum

Very stable from pH 4 -10.

Nongelling – used primarily as a viscosity builder, stabilizer water binder

More highly substituted than LBG –

more soluble & hydrates fully in cold

water giving high viscosity

A linear chain of mannose with single galactose units attached as side chains

Locust Bean Gum (LBG)

Canned foods, sauces, desserts, beverages, ice cream, processed meats

Primary functions: thickening, stabilization of emulsions, inhibition of syneresis

LBG is non-ionic – stable over the pH range of 3.5 to 11.0

Does not form a gel by itself – but can gel

when combined with xanthan gum

Insoluble in cold water & must be heated

dissolve to max viscosity develop when

heated to ~95C, then cooled.

Galactomannan gums – made up of

mannose & galactose in a ratio of 4:1

Come from seeds of the leguminose

Ceratonia siliqua (indigenous to

Mediterranean countries)

Carrageenan

Gelation of Carrageenan

Cations are important in carrageenan gelation. It

is believed that Ca2+ and K+ ions form bridges

between adjacent double helices through an

electrostatic binding to two adjacent sulfate

groups, thus stabilizing and strengthening the

network.

In a concentration as low as 0.5%, K- and I-carrageenan have the ability to form thermoreversible gelsvupon cooling of hot aqueous solutions containing various cations (e.g., K+); L-carrageenan does not form gel

types of carrageenan

Iota (-carrageenan)

Lambda (-carrageenan)

Kappa (-carrageenan)

structure is composed of linear galactan

polysaccharides that have a sulfate content of 15-40%.

highly refined extract of seaweed

from the rhodophyta family.

Gum Arabic

Uses

Function as an emulsifier & stabilizer in

soft drink emulsion (30% of world supply)

Promote stabilization of foam in beer

Encapsulation agent - to encapsulate volatile flavour compounds

confectionery products – to retard sugar

crystallization & to promote emulsification

Least viscous & the most soluble of all

the hydrocolloids – up to 55% solid

concentration can be used

Dissolve easily in hot/cold water

Complex structure – polysaccharide

containing galactose, rhamnose,

arabinopyranose, arabinofuranose,

glucuronic acid.

Alginate

Applications

Propylene (esterified glycol alginate form of alginate) has emulsification property – commonly used as stabilizer in emulsions like mayonnaise/low-fat mayonnaise.

In beverages, alginate act as a thickener & stabilizer – e.g., in dry mix fruit drinks, alginate gives fast hydration & mouthfeel.

excellent stabilizing effect in frozen products; e.g., used in ice cream to avoid crystallization,

can form gel in cold water in the presence of Ca ion; the gel is thermo-irreversible.

ratio of M:G & the MW of polymer

determine the solution and gelling

properties of alginate

Made up of blocks of Dmannuronic

acid (M-blocks) & Lguluronicvacid (G-block)

Derived brown seaweedv(Laminaria hyperborea)

Pectin

Typical Pectins Used

In fermented /directly acidified dairy products

As stabiliser

in fruit juices fruit drink concentrates –

also to provide a “natural mouthfeel”

Jams, jellies & preserves

Jam with suspended fruit particles requires rapidset

HM pectin

primary gelling agent in jams & jellies

Types of Pectin

Low Methoxy Pectin (LMP)

ALMP – very Ca2+ reactive : assist gelation in low sugar

fruit preparations, e.g. low-sugar jams & jellies

LMP – less Ca2+ reactive than ALMP:used as a

thickening agent in yoghurt fruit

form gel with Ca but lose gelling ability asDE increase

Form gels in the presence of Ca2+, with a low solids

content & wide pH range (1-7) [but soluble solids can

be up to 85%]

DE < 50% — two sub-groups:Conventional low methoxyl pectin (LMP),Amidated low methoxyl pectin (ALMP)

High Methoxy Pectin (HMP)

As DE increase, ability to form gel increase

gels at high solids & low pH

not heat reversible

firm & short structure,

clear & transparent, excellent flavour

release

Setting times vary from 1-3 min to > 1 h

Commercial high methoxy pectin: DE 58% to

75%

Natural form is called

protopectin (insoluble)

Derived from the peel of citrus fruits (lemon, lime,orange), apple pomace, sugar beet, sunflower heads