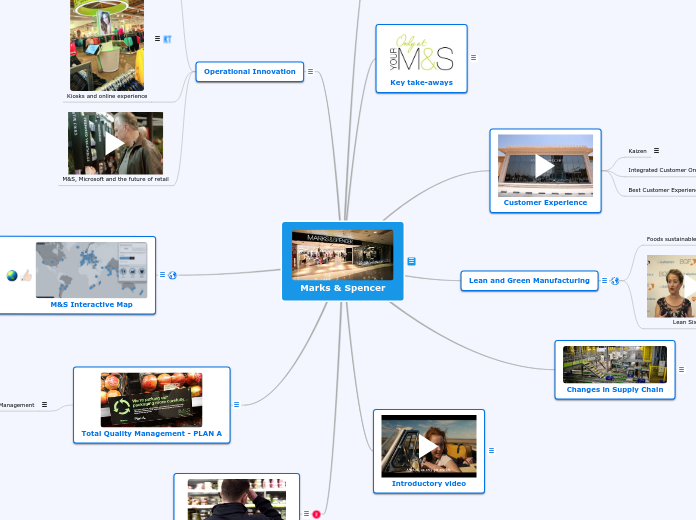

Marks & Spencer

IE Business School - Master in Management

Operations and Supply Chain Management

Section 3

Philippine de Baenst

Marks & Spencer

M&S is a very interesting company to analyse with regards to Operations and Supply Chain Management. Since its creation, it has

has always followed the principles of Quality, Value, Service, Innovation and Trust and has become one of the leader in retail organisations. It has succeeded in constantly reinventing itself; while offering qualitative products, following lean and green management, innovating and putting its employees as well as its customers at the core of its business.

This is the reason why M&S has been so successful, distinguished and popular among people.

Hope you will enjoy the journey!

Delivering Excellent Service

MARKS & SPENCER’S CUSTOMER SERVICE TRAINING ACHIEVES LANDMARK ACCREDITATION STANDARD

The Institute of Customer Service has announced that Marks & Spencer has successfully achieved the Institute's TrainingMark accreditation for its customer service training programmes.

TrainingMark is the standard set by the Institute of Customer Service for company training programmes. Achieving TrainingMark demonstrates a commitment to delivering excellent customer service in all areas of the business through high quality training.

Marks & Spencer runs one of the UK's biggest retail customer service training programmes, 50,000 store colleagues covering full-time and part-time staff and managers.

Jo Moran, Head of Head of Customer Service for Marks & Spencer explains why TrainingMark is a key element of Marks & Spencer's customer service strategy:

“At Marks & Spencer, we differentiate ourselves through excellent customer relationships and service. To deliver this, it's essential that our people receive the highest standards of customer service training. TrainingMark accreditation provides independent assessment and benchmarking of our training programmes to ensure that our employees are equipped to provide the excellent levels of service our customers expect.

Full article available on: https://corporate.marksandspencer.com/media/press-releases/2012/customer_service_training_achieves_landmark_accreditation_standard

Total Quality Management - PLAN A

PLAN A 2020 was launched in 2014 with a focus on greater transparency and engagement of Marks & Spencer customers, employees and suppliers.

M&S commitments are the following:

- Develop mechanisms to help their customers identify products with Plan A qualities (or ‘attributes’) online to encourage their purchase by 2015.

- To have at least one Plan A quality (or ‘attribute’) in all M&S General Merchandise and Food products by 2020, with 50% of products having at least one Plan A quality (or ‘attribute’) by 2015.

- By 2015, M&S will publish details of how they define and measure Plan A product qualities (or ‘attributes’), identifying hotspots and details of our collaborations.

At M&S we define a Plan A product attribute as:

A quality or feature regarded as a characteristic or inherent part of a product which has a demonstrable positive or significantly lower environmental and/or social impact during its sourcing, production, supply, use and/or disposal.

Supplier Relationship Management

Retailers are increasingly scrutinised on the strength of their relationships with suppliers and their local communities as well as efforts to continually improve working conditions and promote fair trading practices.

As one of the most trusted brands on the high street, M&S believes its role is to reassure their customers and key stakeholders that they are a fair partner. Being a fair partner covers the prices M&S pays to suppliers and producers of raw materials as well as the support they provide to communities where they trade. It also includes their responsibilities to ensure good working conditions throughout their supply chains and to source all products with integrity.

M&S Interactive Map

Marks & Spencer has launched an interactive map that shows customers and stakeholders where every type of fish or seafood it sells is either caught or farmed. It also lists the locations of all the company' suppliers and factories such as cattle and dairy farmers and details where the wool comes from to make M&S products.

It is a very nice and interactive tool, have a look!

Hannah Macintyre, M&S’ Marine Biologist, said: “We know how much our customers care about responsible fishing. We wanted to share with them all the data we have on where our fish comes from and how it is caught. Transparency is an important part of the trust that our customers and stakeholders put in us, that’s why we’ve published this smart tool which lays bare our whole fish supply chain, wherever it is in the world and however it is fished or farmed.”

Operational Innovation

The success of today’s M&S owes a great debt of gratitude to a long and rich track record of innovation. These are the foundations on which their business has been built and the points of difference that have set M&S apart on the high street for generations.

Giving their customers something new, something appealing, something that stands out from the crowd has meant their business had continued to evolve. Whether it’s a big idea that meets their customers’ needs or focusing in on the smallest detail, innovation has been the product of M&S unceasing drive to do things differently and make things better. Here are just a few examples that illustrate the point.

M&S, Microsoft and the future of retail

Kiosks and online experience

Integrated store and online experience

M&S is using the terminals to make the instore shopping experience more convenient for customers by allowing them to move more freely between shopping channels and make payments as smoothly as possible. It used its project management and quality assurance experience to help M&S develop and de-risk this first-of-a-kind instore technology.

Kyle McGinn, head of M&S new channels and digital labs, said in a statement: “Our goal is to be the best of M&S in every store and these kiosks do that in a convenient and practical way, whilst also providing inspiration and choice. We’re encouraged with the customer feedback we’ve received so far and the performance we are getting from these devices.”

Online Food Delivery Service

Introductory video

Marks and Spencer is one of the leading retail organizations in UK which sell stylish, quality and great value clothing and home products , also quality food. They are one of the most popular brand among people not only in UK but globally. They have more than 600 stores in UK and constantly increasing many more around the world. It was founded when in 1884, Michael Marks opened a stall at Leeds Kirkgate Market. In 1901, its first registered store was located at Derby street, Manchester. By 1924 they started expanding and the head office moved from Manchester to London. Implementation of new policies and maintenance of services and value kept on adding to the success of Marks and Spencer. In 1998, it became the first retailer to earn a profit of £1 billion.

Changes in Supply Chain

The company is planning to open a mechanised clothing and homeware logistics centre in Hertfordshire. This facility will be opened in 2019 and create over 500 jobs in the local community. The new facility looks to drive better service and heightened availability to customers who are demanding lower prices from retailers. The logistics centre, which will be managed by a third-party logistics supplier, is planned to be a 495,000-square foot facility and will be the hub for 150 stores in the South East of England.

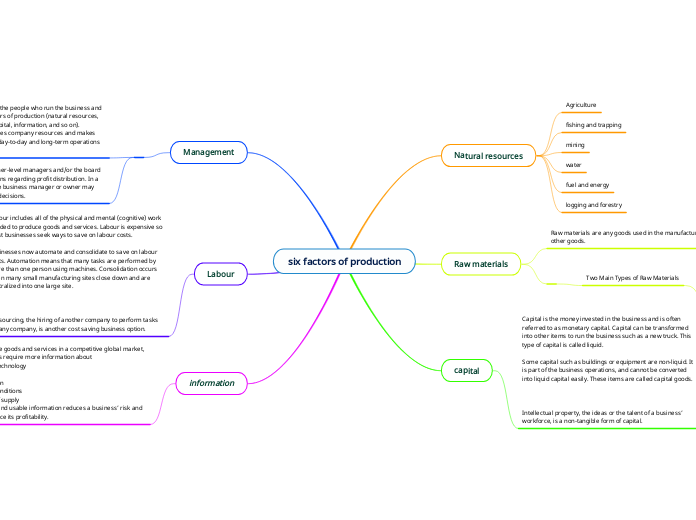

Lean and Green Manufacturing

Marks & Spencer has been a pioneer in terms of sourcing food and drink products from suppliers that meet lean, green and ethical manufacturing criteria.

The company conducts audit processes with its suppliers and quickly realised the importance of embedding 'lean thinking' to ensure the food supply chain is resource efficient and fit for the future.

"We decided to work with our suppliers alongside external technical experts to develop an M&S bespoke standard.The initial draft in 2009 was based on real-life learning from a pilot project run by the 2 Sisters factory in Flixton, designed to identify which practices delivered business benefit as well as positive environmental and social outcomes, and how to motivate and reward continual improvement, innovation and ambition" Marks & Spencer on How we define Plan A product attributes

Lean Six Sigma

Foods sustainable factory programme

From the article " SILVER AND BEYOND – FOODS SUSTAINABLE FACTORY PROGRAMME "

In the "Stories" section of Marks & Spencer website (see full text attached in the link)

"So what is the framework? Suppliers work through the bronze, silver and gold framework across 3 pillars – HR , Environment and Lean Manufacturing and are awarded an overall score. We think that to achieve silver is really challenging so we’ve set a target that 30% of our food will be sourced from ‘silver’factories by 2015. This isn’t another audit, it enables suppliers to prioritise what’s important to them and work over time to really embed change and excellent performance. We are not stopping at silver though and this year ‘crowned’ our first gold site and have several more in the pipeline.

So what does being a silver factory mean? In terms of people & HR the site has a clear and ambitious people plan and metrics, employees are actively motivated and rewarded and there is superb training in place for all levels. From an environmental point of view,the site has a clear environmental plan and metrics and a management system to underpin this; Employees when asked know about the plan and their role in delivery and Key raw materials have been risked assessed. Finally from a lean manufacturing point of view we are looking for a Dynamic business environment with an increased pace of change and a Changed workforce mind-set: people are empowered and able to generate ideas from all tiers with continuous improvement embedded across the business and into the supply chain."

Customer Experience

Best Customer Experience - award

Marks and Spencer has been named the company with the Best Customer Experience at Loyalty Magazine’s annual awards, recognising that the retailer places the “customer at the heart of every strategic decision”.

The award was entered in partnership with InMoment, Marks and Spencer’s provider of customer experience intelligence solutions for its international Voice of Customer programme.

The Loyalty Magazine Awards body said in a statement of Marks and Spencer’s winning customer experience strategy: "This is an excellent example of using innovation on a global basis to engage with customers in order to lift business using the M&S toolset. It allows the retailer to impact on hundreds of thousands of customers in multiple countries at the same time.”

Commenting on the win, Marks and Spencer’s international operations manager, John Heatherington added: “Our customer experience programme has gone through a complete overhaul since 2016, and we’ve worked diligently to create a strategy which enhances the way we connect with and listen to our customers.

Access to full article on: https://fashionunited.uk/news/retail/marks-and-spencer-recognised-for-customer-experience/2018062530375

Integrated Customer Ordering Service

The retail market is immensely competitive and keep on upgrading their information system to meet the requirements of services. M&S started using up-to-date information system in its ordering system which made it stand different from other rival organisations. On 19 April, 2005 Marks and Spencer signed an alliance with Amazon Services Europe. In this agreement, Amazon Services Europe will host and provide with synchronized information system to M&S websites, telephone ordering systems and in store ordering systems. ICOS was launched in 2006 and was based on Microsoft Windows NT Server and Oracle 10g databases. It also comprises various intelligence tools using DOS applications and is called as Rumba Server in M&S. This system enables ease of access of data and information across all stores and offices of the organisation. The system is efficient in dealing with the orders, vendors, manage information across the organisation, control the supply of incoming and outgoing products through a common database which gives solution to all problems related to above categories.

The business process improvement team has not only developed this application but has also installed it in all stores where in store ordering is available. The information system had to meet challenges like connecting all stores to common database so that all product related information and management related information could be shared across. It was not easy to interrelate thousands of product data and ordering information on websites, in stores and in offices. The system application must be in a way that the data is easily accessible through all channels and can be used through company intranet without paying heed to its location. The system included taking orders, order processing, order dispatch, order location, stock control and order prices. This helped M&S to expand their business systematically.

Kaizen

M&S strongly believes in Kaizen concept: it has established many feedback mechanisms in order to get valuable feedbacks from its customers and apply those suggestions for better performance. Kaizen is a process that never ends at M&S.

The decision to invest into a fresh voice of customer (VOC) approach and software application was driven by a desire to get customer insights into the business faster and more comprehensively. Historically, Marks & Spencer had been using a mystery shopper program, sending one mystery shopper to visit each store once per month to ascertain the level of service provided.

M&S then launched a Web-based survey asking customers to rate their overall satisfaction with the shopping experience from 0-5, as well if they would recommend the brand to family and friends.

To encourage customers, M&S offered discounts, vouchers and gifts in return for completing the survey.

Key take-aways

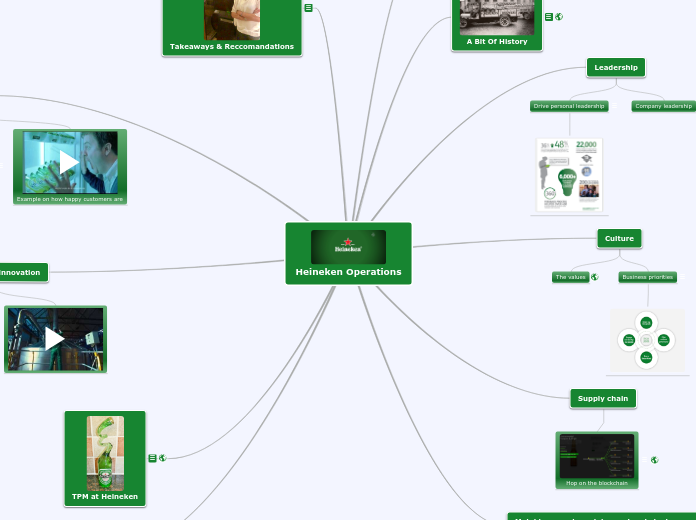

I hope you enjoyed going through this mind map and could gather deeper insights into Marks & Spencer unique Supply Chain management!

To sum up, the company successfully achieved to offer quality products as well as excellent service, maintain close relationships with its suppliers, innovate in numerous ways and constantly put its customers at the heart of every strategic decision. I believe M&S is and will remain a pioneer in the food and textile technology.

However, I would like to point out the increasing competition retail stores are experiencing nowadays. Online commerce has disrupted the traditional retail industry and pushed its players to redefine themselves. More than ever, Marks & Spencer needs to adapt to the current landscape in order to meet consumer needs and keep delivering high quality goods at an affordable price.

Greater Competition & Challenges

M&S faces greater competition as the internet has made it easier than ever to shop around, compare prices and access fashion from around the world. About a quarter of fashion and footwear is now bought online in the UK, says retail expert GlobalData, and the switch from the high street is benefiting the likes of Asos as well as dozens of smaller brands from Boden to Me+Em. M&S has struggled to adapt. It made a massive investment in an automated home delivery warehouse which has struggled to cope with demand.