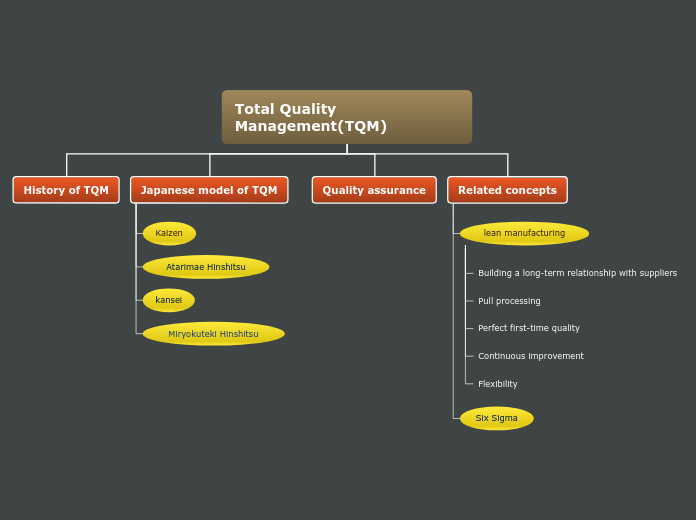

GEARS

Herringbone Gear

Subtema

External gear pumps

Disadvabtages

Difficult aligning during assembly

Manufacturing cost is too high

Improved load carrying ability

Minimum hydraulic shock

Great strength

Quiet and pulse free flow

(Also known as double helical) is a gear designed to transmit power through parallel or perpendicular axes. It works like a helical gear, but, because of its tooth structure, it nullifies the axial thrust.

Bevel Gear

Aplications

Bevel gear in differential

The bevel gear has many diverse applications such as locomotives, marine applications, automobiles, printing presses, cooling towers, power plants, steel plants, railway track inspection machines, etc.

The shafts' bearings must be capable of supporting significant forces.

Must be precisely mounted.

One wheel of such gear is designed to work with its complementary wheel and no other.

Differing of the number of teeth (effectively diameter) on each wheel allows mechanical advantage to be changed.

- It lets you change the operating angle.

They are gears where the xes of the two shafts intersect and the tooth bearing faces of the gears themselves are conically shaped.

HELICAL GEAR

The efficency is less than a spur gear

They are more expensive than spur gears

They tend to have more friction

They can transmit more power between either parallel of right angle shafts

They can be used for high load applicatons

They are more silent than spur gears

Railway industry

Construction Machinery

Automobile Gear Box

They are similiar to the spur gears, but they have a hélix angle between every teeth

There are two types of helical gears

Parallel

Crossed

Worm and worm gear

A worm and worm gear system consists of a worm and worm wheel. The worm resembles a screw, which meets with a worm wheel. It works when rotational power is applied to the worm so it rotates against the wheel and transfers power to the worm wheel.

Disavantages

Gears should be assembled with respective shaft precisely.

The mechanism might produce an annoying sound at a high speed.

The system provide high-ratio speed reduction.

They are used to increase torque or reduce speed.

They are the smoothest and quietest of the gear systems.

Rack and Pinion

Diameter of the wheel infinite

Applications

Railways

Stairlifts

Steering Wheel

Due to the friction, it is under a constant wear, possibly needing replacement after a certain time.

They can only work with certain levels of friction

The wheel is also the most convenient and somewhat more extensive in terms of energy too.

Rack and pinion gives easier and more compact control over the vehicle

Easiest way to convert rotation motion into linear motion

Robust

They are compact

They are cheap

Topic principal

SPUR GEAR

The teeth are parallel to the axix of the gear

They are usually low speed gears

They experience a large amout of stress

They produce a lot of noise

Advantage:

They are highly reliable

They do not have slip

They are compact and are easy to install

Auomobile Gear Boxe

Mechanical clocks and watches

Washing machines

Hypoid gear

Similar to spiral bevel gears except they transmit motion between non-intersecting shafts.The teeth on a hypoid gear are helical

Examples

Sumitomo hyponic drive.

Truck drive differentials, where high torque and an offset pinion are valued.

Disadvantages

Some gears may warp or become brittle in the face of extreme temperatures.

The material requires special care when meshing.

It requires high technology in design and manufacturing.

Requires special EP (extreme pressure) gear oil in order to maintain effective lubrication.

Advantages

Increases the flexibility of a machine design because the axis can be extended to both directions and the height of axis can be set freely in some degree.

Compared to worm, the offset between pinion and gear is small with resultant space savings.

Less sliding and high efficiency result in smaller capacity motors.

Provides quiet operation and additional durability.