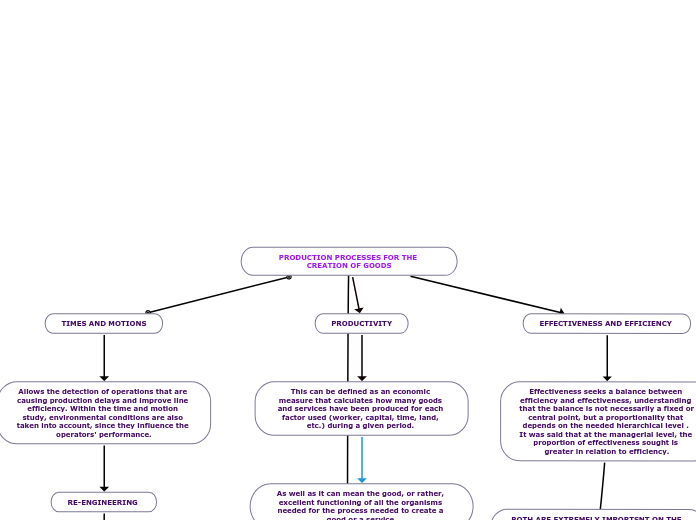

PRODUCTION PROCESSES FOR THE CREATION OF GOODS

BASIC PRINCIPLES ABOUT THE DESIGN OF A PRODUCTION PLANT

One of the most basic principles that are taken into account when designing the layout of a production plant is its distribution, which is an extremely important point to plan ahead.

In addition to the above, there are the principles of satisfaction and safety in plant design.

EFFECTIVENESS AND EFFICIENCY

Effectiveness seeks a balance between efficiency and effectiveness, understanding that the balance is not necessarily a fixed or central point, but a proportionality that depends on the needed hierarchical level . It was said that at the managerial level, the proportion of effectiveness sought is greater in relation to efficiency.

BOTH ARE EXTREMELY IMPORTSNT ON THE PROCESS TO PRODUCE A GOOD OR A SERVICE

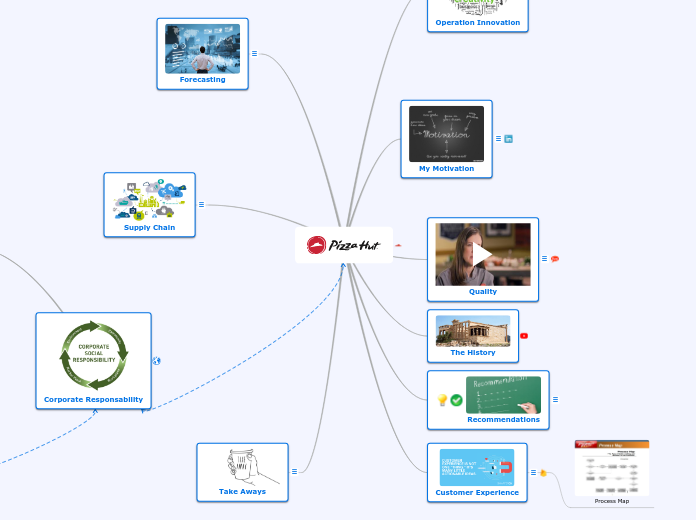

FORECASTING METHODS

Before deeply explaining each of them, it should be known that there exist 3 different forecasting methods, and they are the following:

QUALITATIVE - TIME SERIES - SIMULATIONS

From these mentioned, several forecasting methods are deployed such as the Delphi method, market research, simple moving average, weighted moving average, exponential smoothing, time regression analysis, Monte Carlo, among others.

PRODUCTIVITY

This can be defined as an economic measure that calculates how many goods and services have been produced for each factor used (worker, capital, time, land, etc.) during a given period.

As well as it can mean the good, or rather, excellent functioning of all the organisms needed for the process needed to create a good or a service.

TIMES AND MOTIONS

Allows the detection of operations that are causing production delays and improve line efficiency. Within the time and motion study, environmental conditions are also taken into account, since they influence the operators' performance.

RE-ENGINEERING

Process reengineering involves the radical redesign of business processes to achieve dramatic improvements in productivity, cycle times and quality.

Quality Management refers to programs that affect the improvement of work processes. Process improvement projects would be placed in this line. These would be incremental improvements achieved through the continuous improvement cycle (PDCA).

Process reengineering refers to discrete initiatives that aim to radically redesign processes in a limited time frame. The aim here is not so much to improve ineffective and/or inefficient processes, but to transform them completely.