por Lysten823 Luna hace 10 meses

106

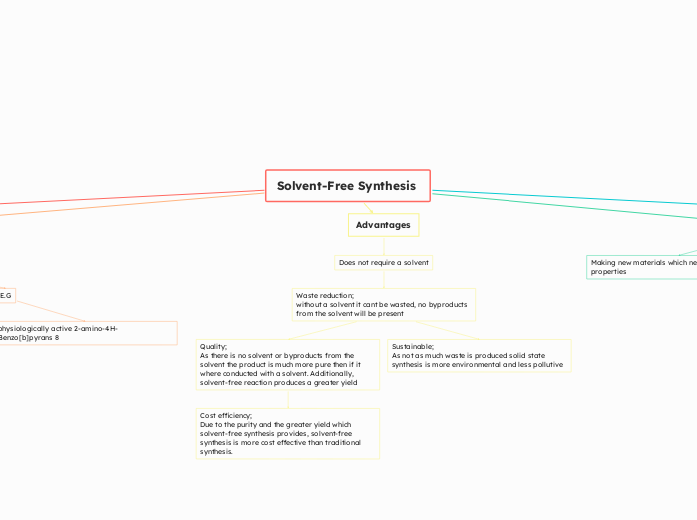

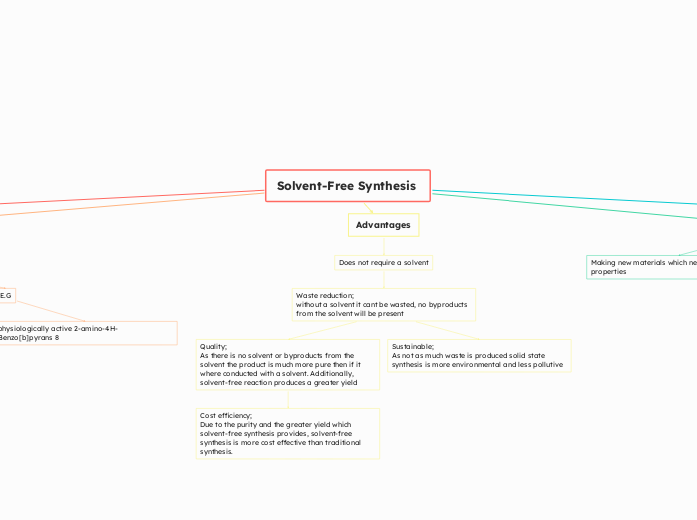

Solvent-Free Synthesis

Solvent-free synthesis represents a significant advancement in the chemical synthesis industry by eliminating the use of solvents, thus reducing pollution and increasing cost efficiency.

por Lysten823 Luna hace 10 meses

106

Ver más

Sustainable; As not as much waste is produced solid state synthesis is more environmental and less pollutive

Quality; As there is no solvent or byproducts from the solvent the product is much more pure then if it where conducted with a solvent. Additionally, solvent-free reaction produces a greater yield

Cost efficiency; Due to the purity and the greater yield which solvent-free synthesis provides, solvent-free synthesis is more cost effective than traditional synthesis.

physiologically active 2-amino-4H-Benzo[b]pyrans 8

Carboxymethyl Cellulose (CMC)

Historically, this theory was used to preserve food product, remove the median of the reaction thus slowing it down considerably.

Pollutive

Due to creating waste it is often inefficient