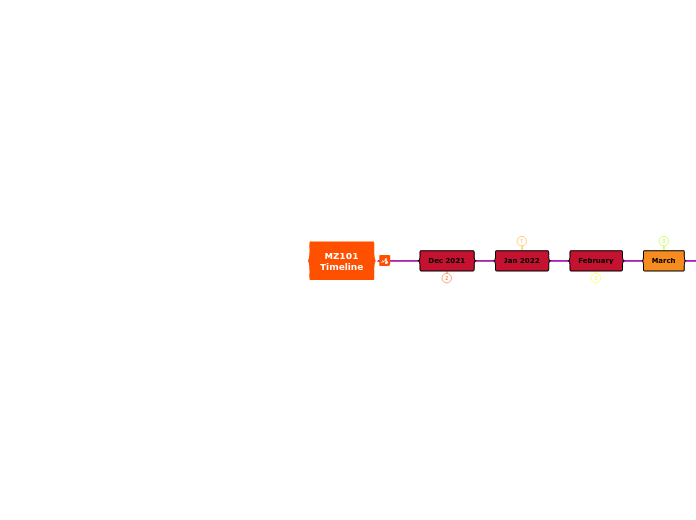

MZ101

Timeline

Dec 2021

Jan 2022

February

March

April

May

MZ101 robustness testing plan

MZ101 application testing plan

Release MZ101-P1 drawings for

fabrication

Build MZ100-2 for testing critical

controls design changes

RT mobility application

study complete for JLG mobility

base requirements

Benchmark MZ101 cost

June

Resolve motor & gearbox

supply chain issues

High level manufacturing strategy

outline for new building setup

Primary function testing

and debug

Evaluate use cases of all current

ML150 accessories

July

Review FEA Results

Perform first full FEA of production

intent design release

Validate critical functions

of wireless handle w/ gripper

August

Perform second full FEA of production

intent design release

Electrical documentation complete

with all critical components for

manufacturing MZ101

Setup electric gripper testing

on ML150 for application,

debug, and robustness

Work with vendors to get forecast

and lead time understood for long

lead electronics.

Executable manufacturing plan

for setup in new building

Start ordering long lead electronics

to protect production supply

Marketing strategy outline

MZ101 official production forecast

for vendors to protect supply chain

September

Validate production intent

motor controls w/ temperature

compensation complete

Finalize complete software

validation plan

Marcus on leave

Marketing pictures and videos???

Working MZ101-P1A production

intent prototype

Prepare customer design review

application presentation

Customer facing spec sheet

GUI layout requirements

outlined

Working MZ101-P1B production

intent prototype

October

Production design release for 1st

manufacturing test run (Rev A)

Customer R&D design review

application meeting

Production software functions

locked down

Inhouse testing with real masons

MZ101-P2A design release?

(Parts or machine)

GUI requirements locked down

Risk assessment complete

Draft risk assessment complete

Start system software validation

and debug for production

Show unit / marketing requirements?

November

Executable marketing plan

MZ101-P2A working unit?

Pre-orders?

GUI complete

December

Draft CE assessment complete

Assembly documentation for

manufacturing floor builds

1st MZ101 pre-production unit assembled

and debugged

Software validated

Jan 2023

Final update and release of all

production drawings (Rev B)

Handoff to operations to

execute on manufacturing

Final setup of manufacturing line

CE certification plan complete

February

Operations owns MZ101

manufacturing efforts

World of Concrete

March

1st MZ101 production unit shipped