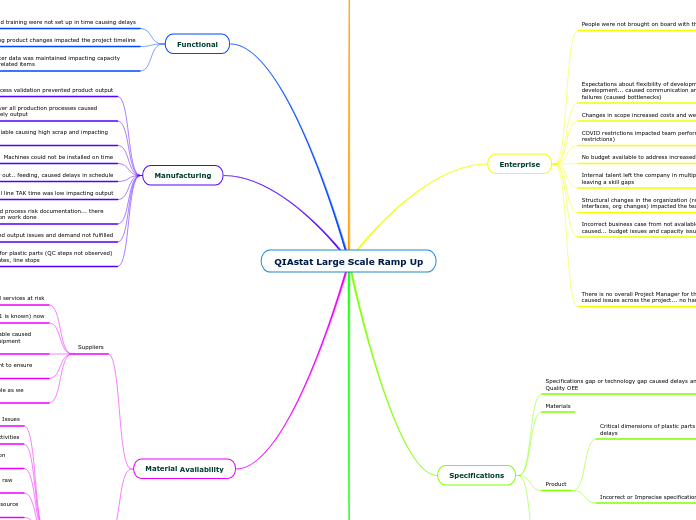

QIAstat Large Scale Ramp Up

Commercial Market

We focused on machine availability, but market demands needed things like flexibility that were not addressed during development

Project agreement/communication needs to clarify the flexibility requirements

We have other production lines that are flexible... Define long term plan for the capacity of each line (including others) and related hiring plan that could address flexibility

Enterprise

People were not brought on board with the right skills

Critical Issue:

Create clear resource plan for the whole project, not just GxP requirements

Link this issue with Project Manager responsibility

Address both hiring and training issues

Identify critical roles that need to be addressed

Expectations about flexibility of development, capacity development... caused communication and expectation failures (caused bottlenecks)

Changes in scope increased costs and went over initial budget

COVID restrictions impacted team performance (e.g., travel restrictions)

No budget available to address increased costs

Internal talent left the company in multiple departments leaving a skill gaps

Structural changes in the organization (responsibilities, interfaces, org changes) impacted the team and stakeholders

Incorrect business case from not available or miscalculation caused... budget issues and capacity issue

There is no overall Project Manager for the program which caused issues across the project... no harmonization

Critical Issue:

Hire a program level PM... this also addresses contamination issues

Define who is doing what to address many of the identified concerns

Address expectations on who is responsible for what across team and stakeholders

Address 'handoffs' when responsibilities change

Specifications

Specifications gap or technology gap caused delays and Quality OEE

Materials

Product

Critical dimensions of plastic parts are not defined causing delays

Incorrect or Imprecise specifications for the product

Critical Issue:

Update requirements document for any mfg. line. A document exists but is outdated, incorrect, insufficient. Make it editable across sites.

Investigate tolerances/specs on production line windows... consider larger windows. (Product Development issue - at least addressed for future projects)

Communicate this risk to the team and raise awareness of the issue

Machines

Machines were not specified correctly or missing causing delays

Subtopic

Contamination

Contamination of raw material caused delays

Critical Items

This is hard to answer at this time... no one knows what compliant manufacturing

Communicate clear definitions via documentation

Need a regular meeting/ communications between LCM with stakeholders. Focus on this.

Mfg lines had issues with product contamination

Improper or difficult cleaning procedures (related to machine design)... contamination of product and excess scrap rate

Contamination related to automation actuators caused delays and Quality issues

Functional

Processes and training were not set up in time causing delays

Ongoing product changes impacted the project timeline

Incorrect master data was maintained impacting capacity planning and related items

Manufacturing

Delayed or failed process validation prevented product output

LSL project did not cover all production processes caused lower OEE and ultimately output

Processes were not reliable causing high scrap and impacting output

Machines could not be installed on time

Tools wear out.. feeding, caused delays in schedule

Overall line TAK time was low impacting output

Insufficient or outdated process risk documentation... there was not enough revision work done

Too low OEB caused output issues and demand not fulfilled

Quality issues related for plastic parts (QC steps not observed) caused higher scrap rates, line stops

Material Availability

Suppliers

Single sourcing put materials and services at risk

ACTION: Set up new suppliers (at least 1 is known) now

Suppliers need raw material that was not available caused delays... made it difficult to set up QIAGEN equipment properly

Time for qualification reviews were not sufficient to ensure quality of documents etc.

Services were not capable or were not as flexible as we needed

Internal Processes

Critical Issues

Confirm that Procurement has initiated required activities

Not all material is covered in BOM (e.g., mfg consumption mtl.) Address planning for non-MRP items

3 lines sharing the same materials have large impact on raw materials and supplies in general

Unable to stage materials due to space constraints or resource constraints... causing delays

Raw material were not ordered in time causing delays

Capacity is limited or too much inventory... forecast is wrong. Unable to meet Max or oversupplied for Min scenario

Did not have critical materials in stock

Investigate storage issues for each scenario... which may impact capital budget

New types of materials were not available because we didn't initiate efforts soon enough to assure stock

Set up training for new processes