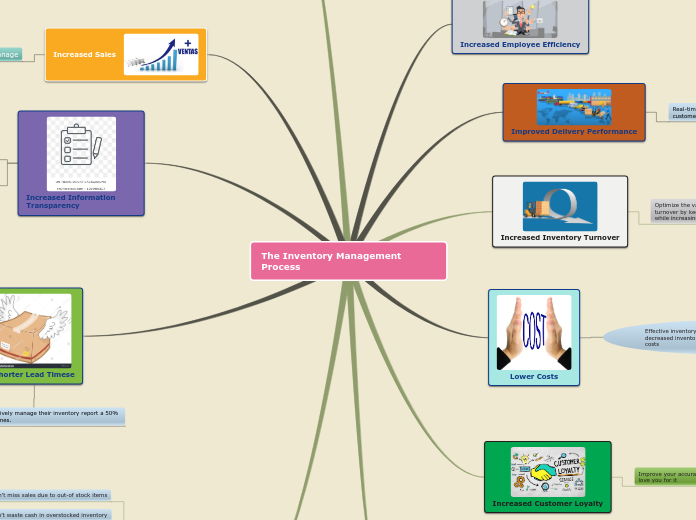

The Inventory Management Process

Increased Employee Efficiency

Good inventory management solutions save time. Less time spent on managing inventory results in greater productivity for you and your clients.

Improved Delivery Performance

Real-time inventory updates improve the flow of goods to customers.

Increased Inventory Turnover

Optimize the value of goods you have and increase inventory turnover by keeping fewer slow-moving products on hand, while increasing your stock levels on profitable goods.

Lower Costs

Effective inventory management practices help result in decreased inventory write-offs, plus lower inventory holding costs

Increased Customer Loyalty

Improve your accuracy and efficiency, and your customers will love you for it

Decreased Stock-Outs

Businesses who actively manage their inventory report a 10-25% decrease in stock-outs

Accurate Planning

Stay steps ahead of the game and always have the right amount of products on hand by making decisions based on inventory trends

Increased Sales

Actively Manage

Increased Information Transparency

know when you need to order more, when you’re over-stocked, or under-stocked

Know when items are received, picked, packed, shipped, kitted, manufactured, etc.

Shorter Lead Timese

Businesses who actively manage their inventory report a 50% reduction in lead times.

Improving your invenyory

1. Don’t miss sales due to out-of stock items

2. Don’t waste cash in overstocked inventory

3. Improve the accuracy of your accounting and profit reporting

4. Identify issues before they get out of control

5. Customer service

6. Efficient re-ordering

7. Minimize theft and losses

8. Trust in your information systems

9. Minimize warehouse costs

10. Efficient stock take and end-of-year process