par Pablo Dos Santos González Il y a 2 années

124

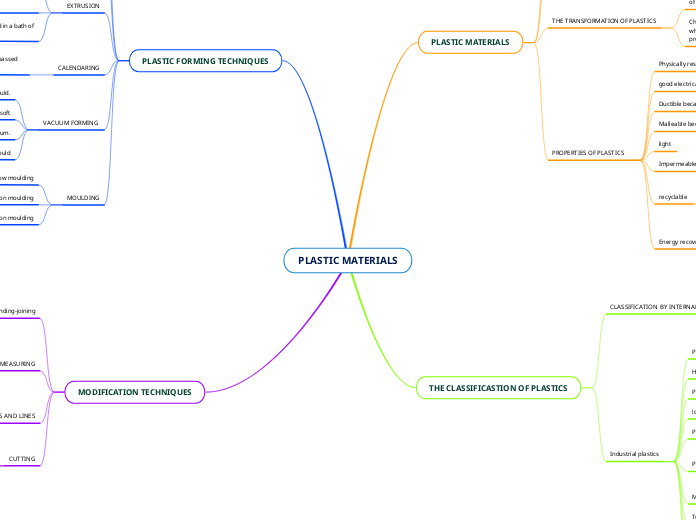

PLASTIC MATERIALS

Plastics encompass a wide range of materials with diverse properties and applications. These materials can be classified into natural and synthetic categories, each possessing unique characteristics such as impermeability, physical resistance, and recyclability.