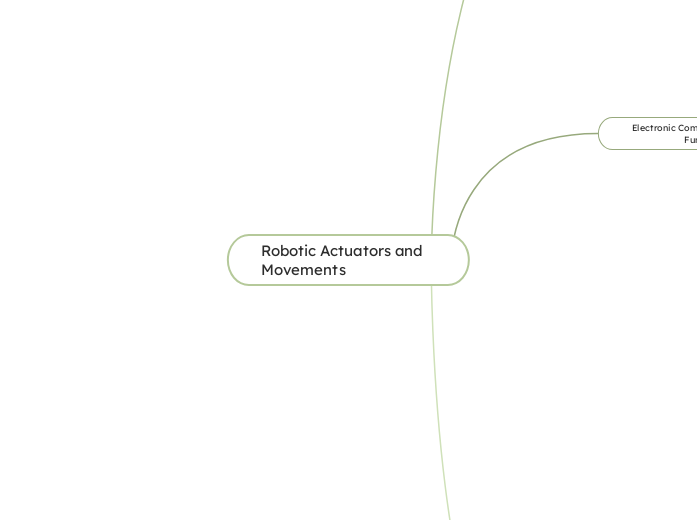

Robotic Actuators and Movements

The relationship between battery and motor and Safety features of Baxter robot

2. Safety features of Baxter robot

Security mechanism

Collaborative design

Working with humans to ensure safety.

Automatic adjustment

Automatically slow down or stop when detecting anomalies.

Flexible arms

Collision protection:

Safely avoid excessive force.

Flexible design

no harm when touched.

Sensor

Human detection

Automatically slow down or stop to ensure safety.

Environmental detection

real-time monitoring of the working environment to avoid collisions.

1.The relationship between battery and motor

Key points

The relationship between the battery and the motor

the battery performance directly determines the motor performance.

Low power

Motor performance decreases, robot slows down or stops.

Motor

Mechanical energy output

Converts electrical energy into mechanical motion to drive robot components.

Motor efficiency

The synergy of battery and motor affects robot speed and performance.

Battery

Battery quality

affects motor efficiency and robot performance

Battery capacity

determines robot running time.

Power supply

Provide power to the robot.

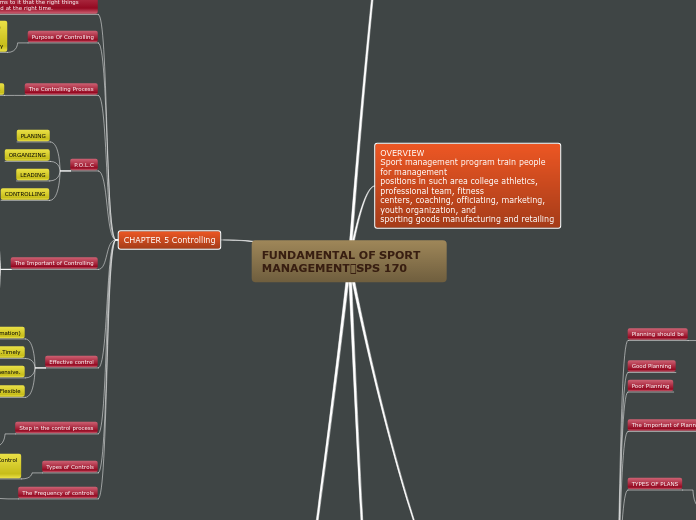

Electronic Components and Their Functions

How does the motor receive signals?

3.Motor Response

After receiving the control signal, the motor adjusts its rotor’s position or action based on the width of the PWM signal.

2.Pulse Width Modulation (PWM) Signal

A PWM signal is a square wave, and the pulse width (the duration of the high signal) determines the motor’s movement or position.

1.Transmission of Control Signals

The computer sends control signals to the motor through a signal wire . This signal is delivered using PWM.

How does the motor know when it has gotten to the right position?

2.Feedback System

position sensor

1.PWM Signals

These signals are sent periodically, typically every 20 milliseconds. Different pulse widths correspond to different rotor angles. By adjusting the pulse width, the controller directs the servo motor to move to a specific position.

About Arduino Uno

The Arduino Uno is easily programmable with computers, which allows users to write and upload code via USB.

Based on the input data and programmed instructions, the Arduino Uno controls outputs like motors.

The Arduino Uno is a microcontroller.

Basic Working principle of Robotics

How robots move

When the battery supplies power to the motors, the motors drive the robots mechanical parts to move.

At the same time, sensors continuously collect environmental data and send it back to the control system, allowing the robot to make precise adjustments and respond in real-time.

3 things drive robotic movement

Control System

Motors

Sensors

End effectors

Different types of end effectors depending on its use

its like the hand of a robot, allowing them to interact with the outside world

Batteries;how they work

When material at the negative electrode is depleted or when the positive electrode cant accept electrons anymore that means the battery wont work

creating electrical energy through chemical reactions

Inside there is positive/negative electrode and electrolyte

The material at the negative electrode releases electrons that flow through the external circuit to the positive electrode, and this process creates an electric current.

Electrolytes help conduct the ions within

Serves as energy source

Motors process of working

Servo and Stepper motors are the most common used ones

Generates a magnetic field through current, causing it to spin

Converts electrical energy into mechanical energy