によって Ian D See 4年前.

186

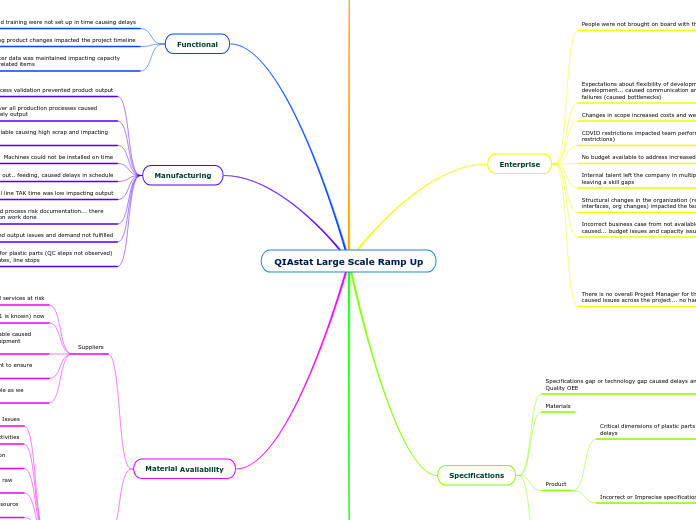

QIAstat Large Scale Ramp Up Copy

The project faced numerous challenges across manufacturing, functional processes, and material availability, leading to significant delays and output issues. Manufacturing was hampered by tool wear, unreliable processes, and low overall efficiency, resulting in high scrap rates and frequent production line stops.