によって Simran Mattu - Humberview SS (2472) 5年前.

403

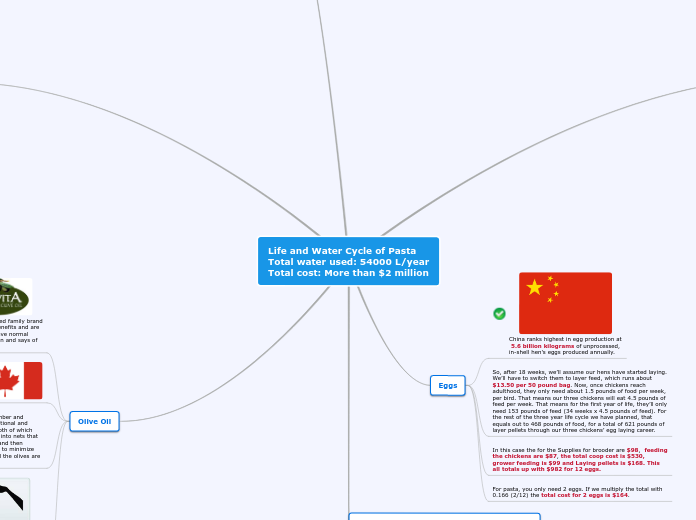

Water Cycle of Pasta

The production and lifecycle of pasta ingredients involve significant water usage and expenses. Salt extraction uses water to create brine, which in turn dissolves the salt and forms caverns in salt beds.