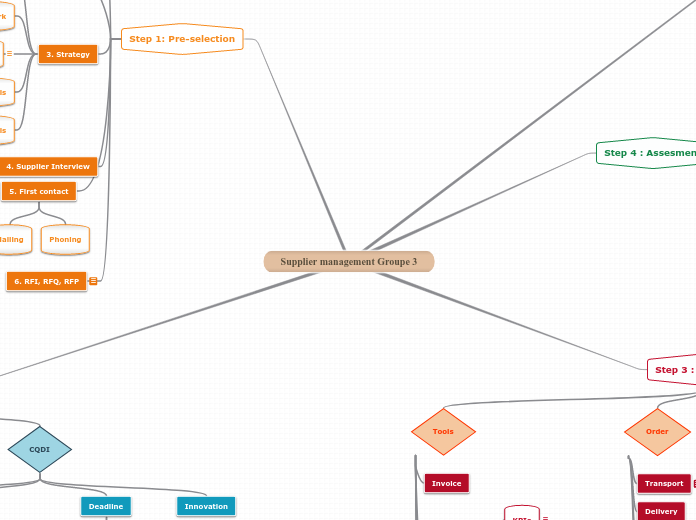

Supplier management Groupe 3

Step 2 : Selection

CQDI

Innovation

Deadline

OTD

Schedules

Quality

Goods

Services

On time Quality

No Quality

Cost

Selection process

Contracting

Selection

Negociation

Bid presentation

Bid analysis

Consultation

Total cost of ownership

Supplier SWOT

Scoring grid

Step 1: Pre-selection

6. RFI, RFQ, RFP

Request for information

Request for quotation

Request for proposal

5. First contact

Phoning

Mailing

4. Supplier Interview

3. Strategy

Risk Analysis

Specifications

Respect of the specifications (needs)

Benchmark

Purchasing Strategy

2. Sourcing

Subcontracting

Client reference

Experience

+ 10 years

Core business

< 75% of the activity's

Réputation

Certifications

ISO 9001

ISO 14001

Location

France

1. Market research

SWOT

PORTER

PESTEL

Step 3 : Follow up

Stock

Critical stock coverage

Duration (in days) of consumption of critical stocks

Advance of stocks

= Stocks in progress / total stock

Stock rotation

Stock rotation rate

Turnover / average stock

(average stock: beginning of year stock + end of year stock / 2)

Actions

COPIL

Treatment purchase request

Penalty

10% up to thirty days late,

20% between thirty and sixty days,

50% beyond sixty days.

From EXW

Order

Forecast

Order per year

Issues

Calculate over 1 year

Delivery

Transport

EXW

Reporting

Assesment grid

Service scorecard

Number of issues / year

Reject

Reject rate

(number of rejects / total volume of the task) X100

Invoice

Step 4 : Assesment

After 6 months

Results

Partnership

Continuous improvement

Means

Financial Analysis

Corrective actions

Currative actions

Indicators

PPM

Part per million

< 10 PPM

OTQs

Rate products comply

(Number of non-compliant products / production total) X100

OTDs

< 96 % OTD

Comparing the number of orders with the number of compliance of deliveries

KPIs

Key Performance Indicators

Tools

Ishikawa diagram

Exemple :

Contents : Inputs: raw materials, subassemblies ...

Equipment : Production and monitoring equipment

Middle : The working context

Methods : Technical Methods and Procedures

Workforce : The staff

Management : Men's management

Dashboard

PARETO

About 80% of the effects are the product of 20% of the causes

Step 5 : Partnership

From 3 evaluation periods

Framework contract

The framework contract is an agreement by which the parties agree on the general characteristics of their future contractual relationships. Application contracts specify the execution procedures.

Relation

Loyalty

Association

Longterm relation

Cooperation

Communication

Joint actions

Co-development

Development approach for people who believe they can learn from each other to improve their practice.

Co-conception

Co-design is the activity of conducting a process of developing a product or service, most often innovative, involving the end user.